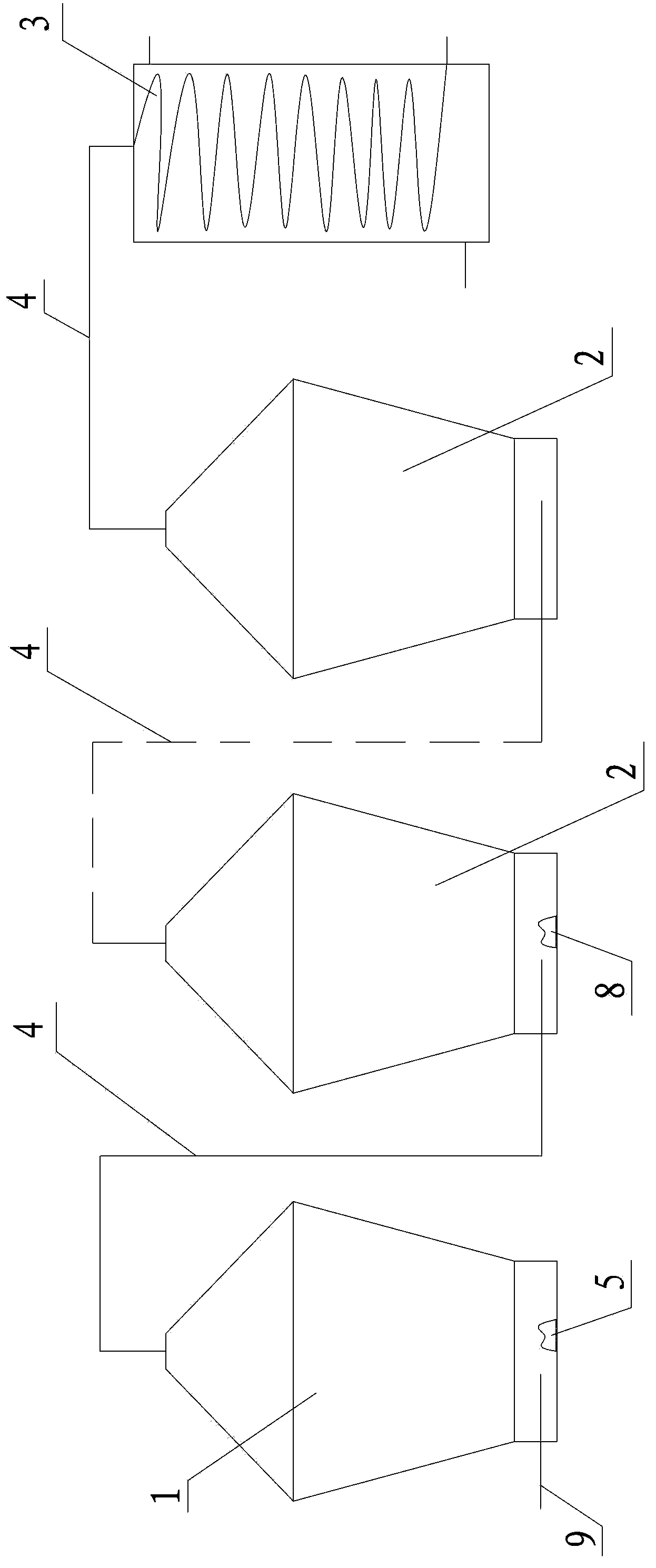

Device and method for extracting bouquet through multistage distillation

A distillation extraction and distillation device technology, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of low alcohol content, too fast or too slow local vapor penetration, and low efficiency of aroma enhancement, so as to increase the content of aroma substances and dilute the vapor penetration Unevenness, the effect of improving the extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

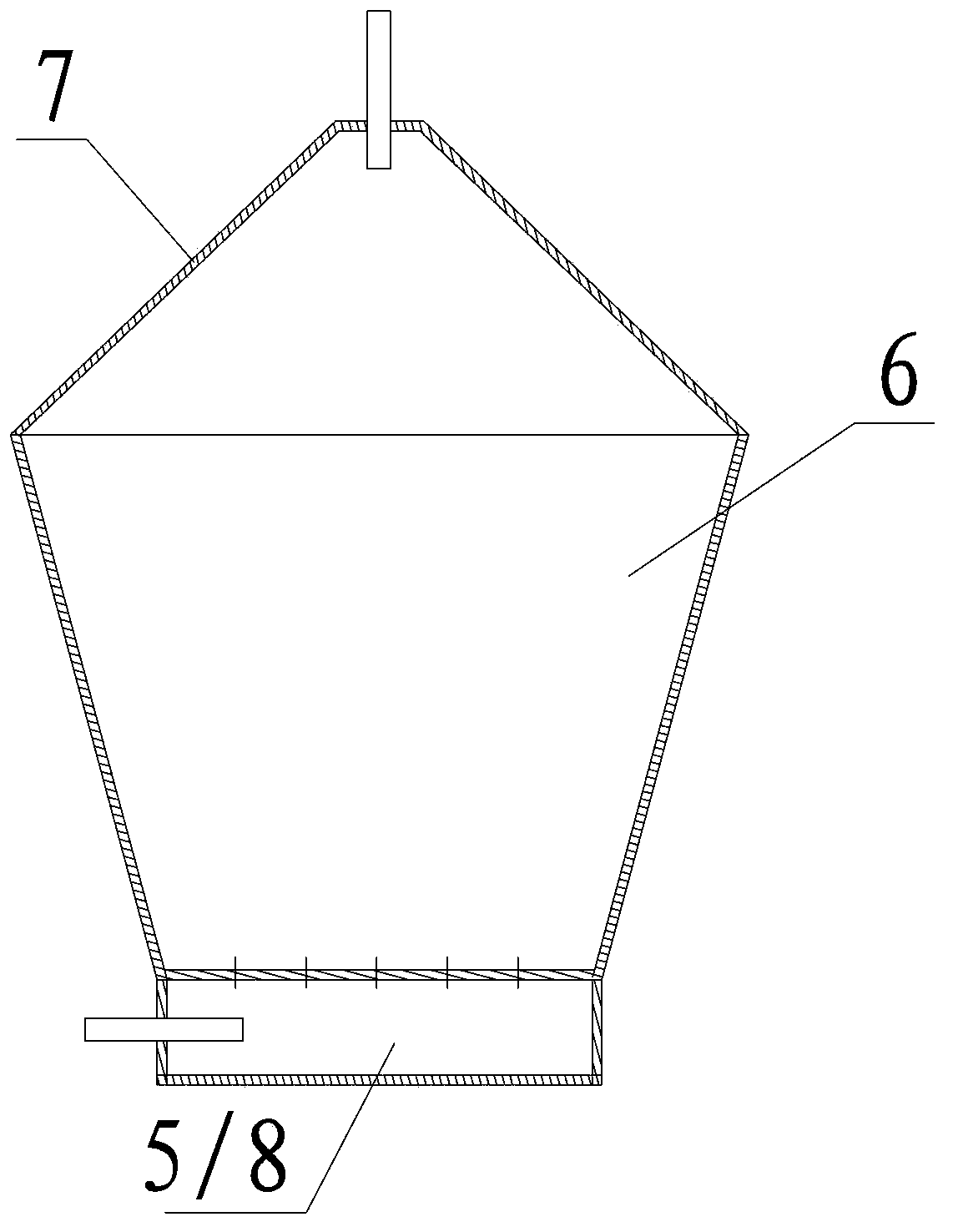

[0033] Using the multi-stage distillation and aromatizing device and method of the present invention, the water vapor of 0.03Mpa is charged into the water vapor storage cavity of the primary distiller 1, and the fermentation tank 6 of the primary distiller 1 is filled with fermentation The filling volume of 60-day fermented grains is 1m3. During the filling process, the height difference between the grains and the water vapor is always maintained at 10cm. After the filling is completed, the wine steam conveying pipe 4 is connected. The wine vapor conveying pipe 4 is then connected to the wine vapor storage cavity of the secondary distiller 2, and the same quality and volume of grains are filled in the same way, and then the distilled wine liquid is received through the cooler.

[0034] An ordinary large retort still is used as a comparison, and the bottom pot of the distiller is also filled with 0.045Mpa water vapor, and the retort is filled with fermented grains of the same fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com