Filament beam finishing oil spray device

A technology of spraying device and tow oiling agent, applied in the field of tow oiling agent spraying device, can solve the problems of reduction of spinning machine position distance, high plant investment cost, low output per spinning position, etc. The effect of optimizing the distribution, improving the quality of oiling, and increasing the number of spinning heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

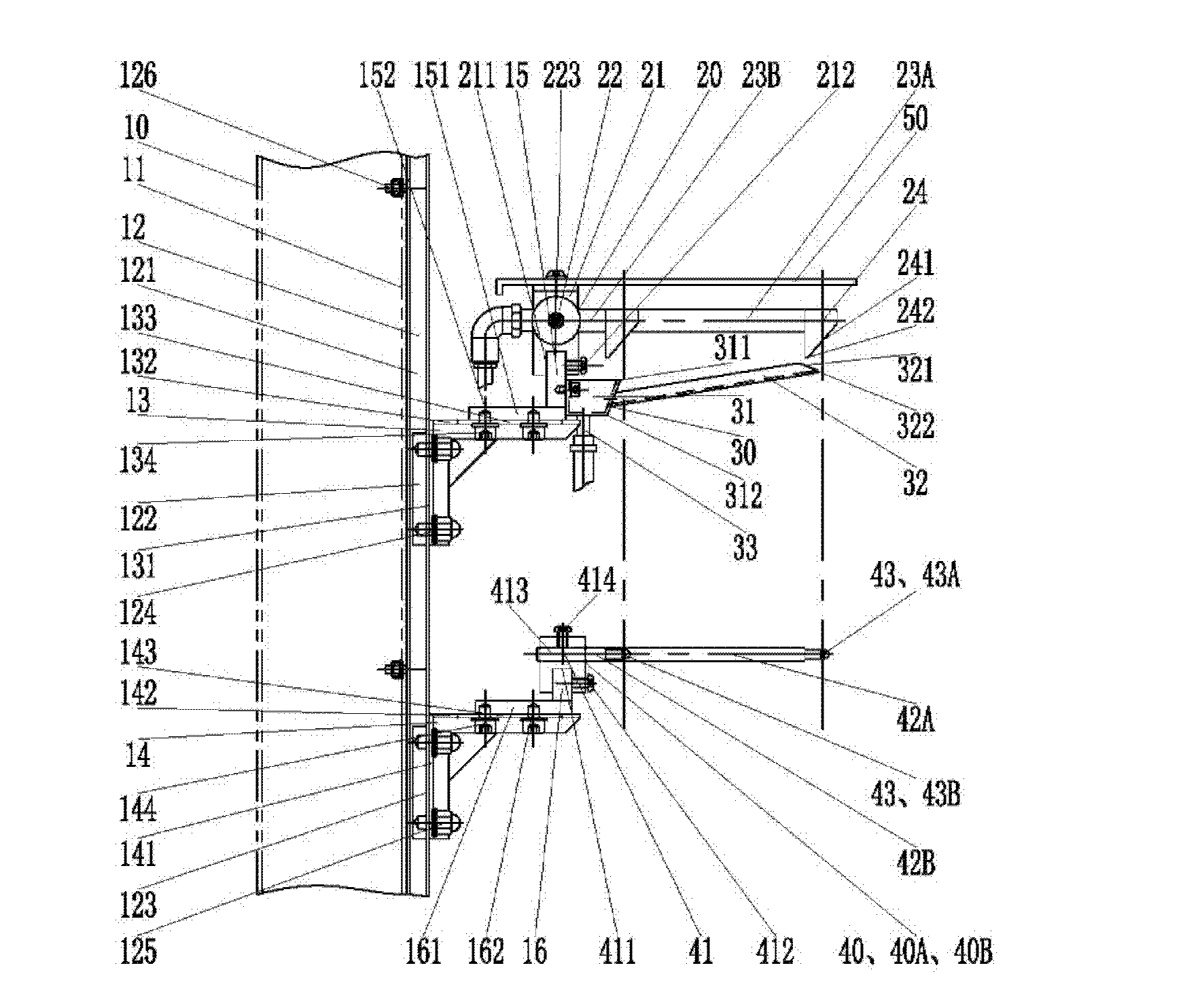

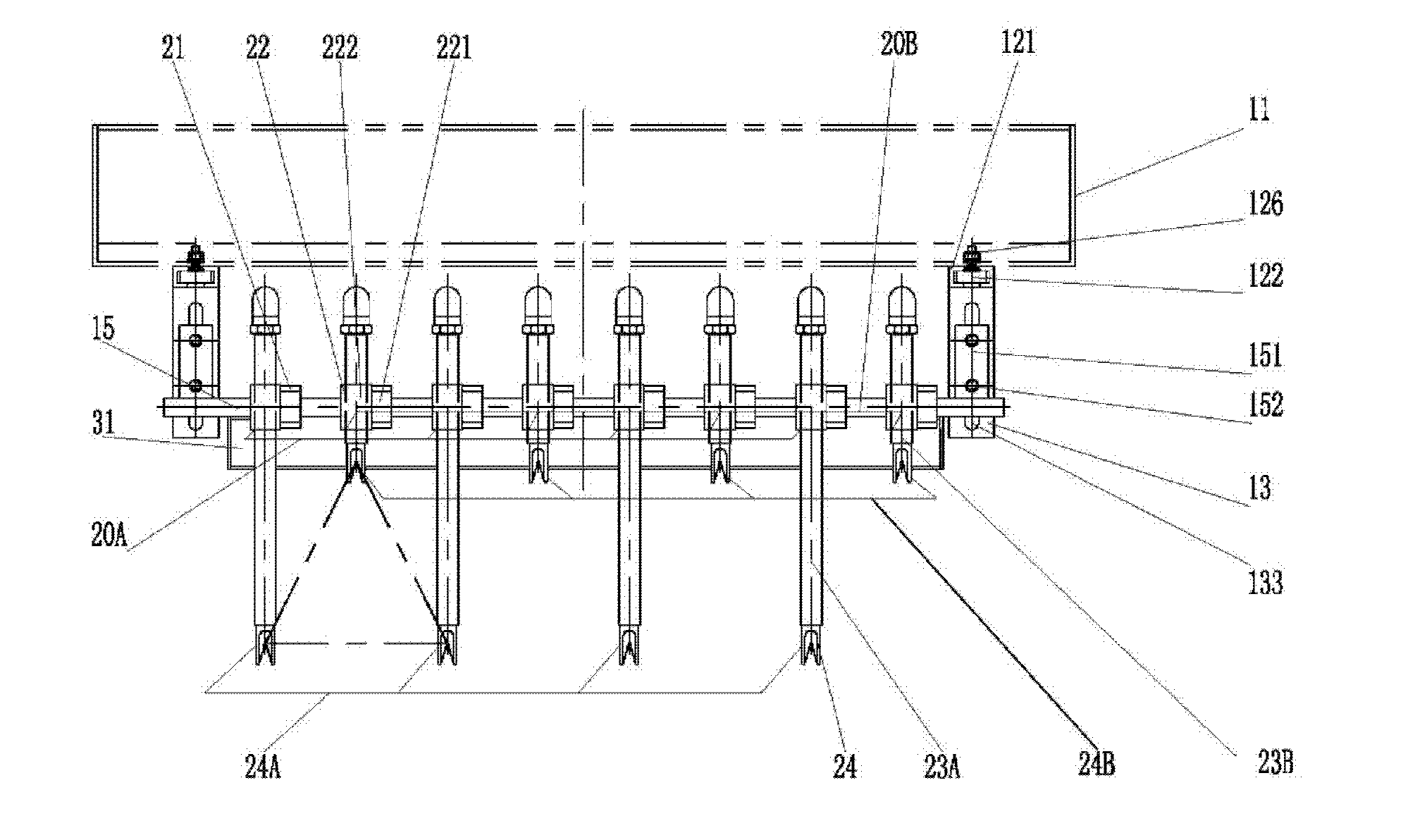

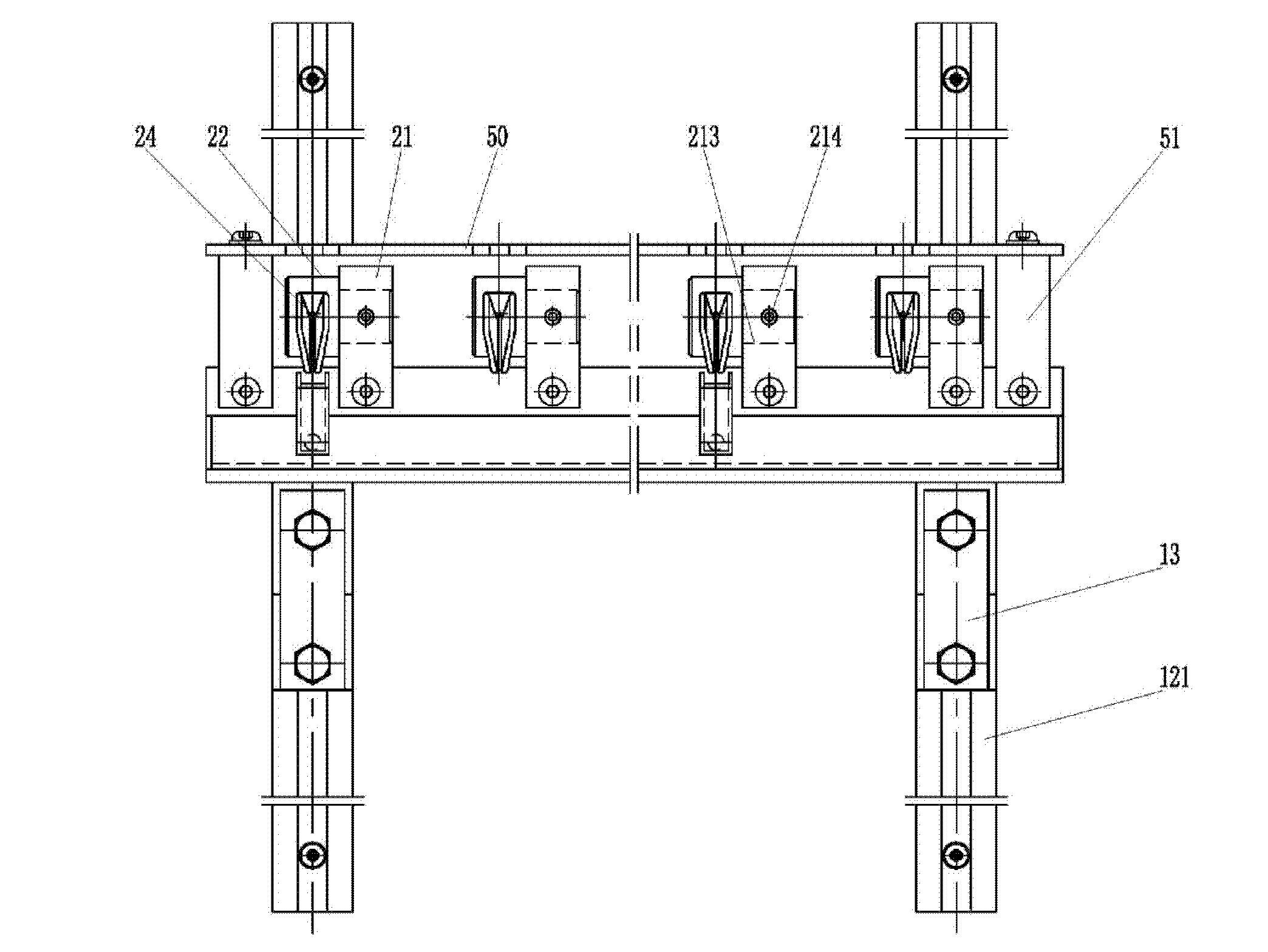

[0028] Such as figure 1 , figure 2 and image 3 As shown, the tow oil agent spraying device of the present invention comprises a liftable vertical frame 10; the upper part before the frame 10 is provided with an upper beam 15, and the lower part before the frame 10 corresponds to the upper beam 15 is provided with lower beam 16 . The upper beam 15 is laterally distributed with a plurality of nozzle parts 20, the number of which is usually 12-32, wherein each nozzle part 20 has a nozzle 24, and the nozzle 24 is arranged in front of the upper beam 15. The guide wire opening 241 of 24 is centered downward, and the oil drip opening 242 of the oil nozzle 24 is behind the guide wire opening 241 and below. An oil return component 30 is provided below the upper beam 15 corresponding to the oil nipple 24 . The lower beam 16 has a plurality of guide wire hook parts 40 distributed laterally corresponding to the oil nozzle part 20, and its number is usually 12-32, wherein each guide ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap