Clutch

A clutch and column technology, applied in the field of clutches, can solve the problems of huge oil supply system, friction and wear, heating, inconvenient control, etc., and achieve the effects of reducing mechanical energy loss, strong power output, and remarkable fuel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

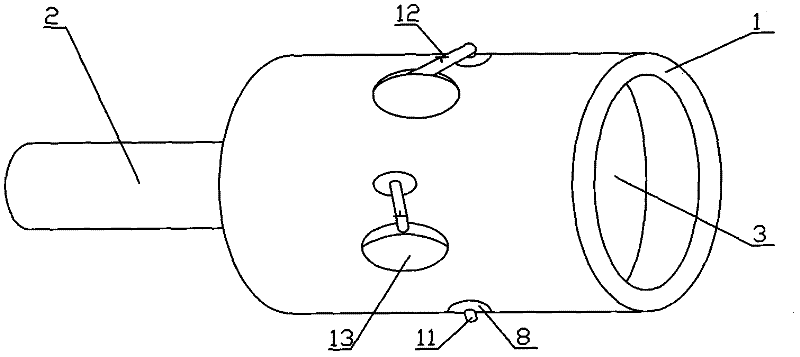

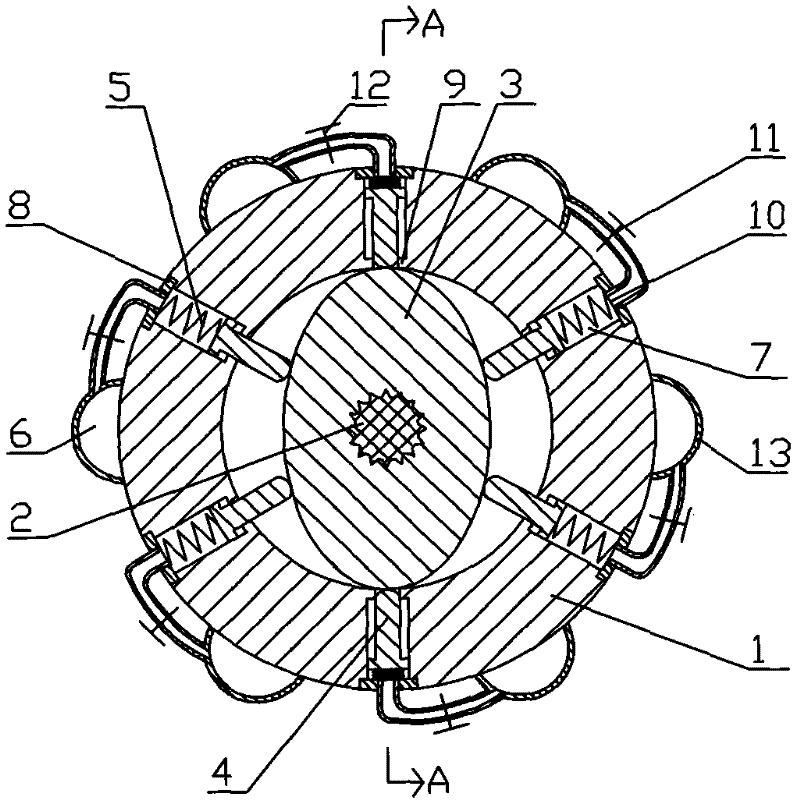

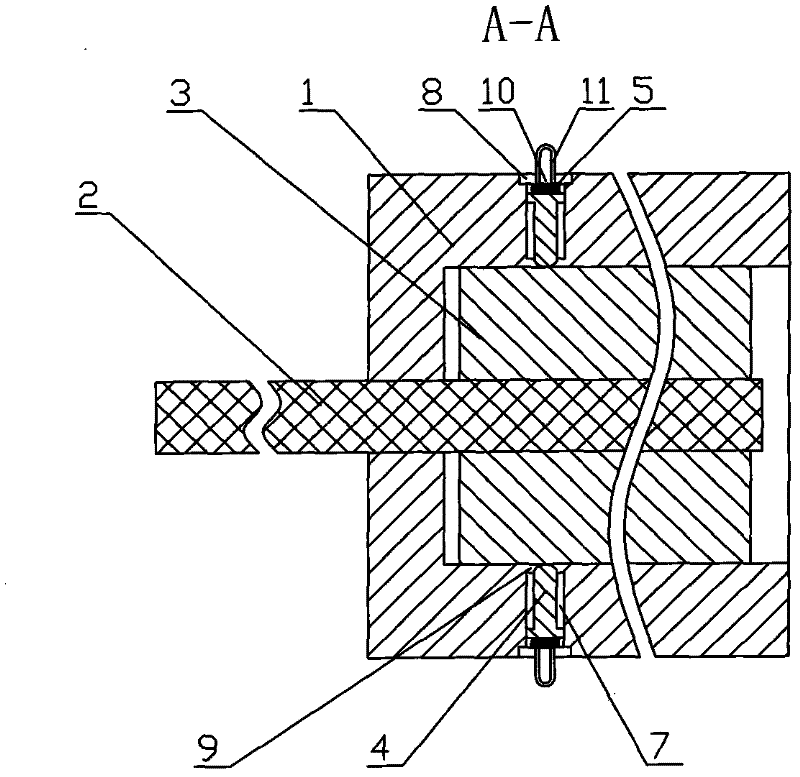

[0025] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a clutch includes a cylindrical driving shaft 1, a driven shaft 2, a driven disc 3, a compression clamp 4, a return spring 5 and a liquid storage device 6, wherein one end of the driven shaft 2 passes through the cylindrical At the center of the bottom end of the driving shaft 1, a driven disk 3 is fixed on the top of the driven shaft 2 in the cylindrical driving shaft 1. The driven disk is a 3-elliptical column structure, and the top of the driven shaft 2 is connected to the elliptical surface of the driven disk 3. Vertically fixed, on the outer wall of the cylindrical driving shaft 1, there are 6 clamping column holes 7 evenly arranged along a cross section perpendicular to the axial direction of the cylindrical driving shaft 1, and the pressing clamping holes 7 on the outer wall of the cylindrical driving shaft 1 The opening of the column hole 7 is sealed and screwed with a compression column hole sealing c...

Embodiment 2

[0026] Embodiment 2: as Figure 4 , Figure 5 Shown, a kind of clutch, compared with embodiment 1, only liquid storage device 6 is different, other structures are all the same as embodiment 1, and wherein liquid storage device 6 comprises hollow liquid storage device housing 14, in liquid storage device housing A piston 15 sliding up and down is provided in the cavity of the body 14, and the cavity of the liquid storage device housing 14 is divided into an air chamber 16 and a liquid storage chamber 17; Oil hole 18, the oil outlet hole 18 communicates with the liquid storage chamber 17, and the oil pipe 11 is connected on the oil outlet hole 18; an air hole 9 is arranged on the top of the liquid storage device housing 14, and the air hole 9 communicates with the air chamber 16; The liquid cavity 17 is filled with hydraulic oil.

Embodiment 3

[0027] Embodiment 3: as Figure 6 As shown, a clutch, compared with embodiment 2, only the driven disc 2 is different, and other structures are the same as embodiment 1, the cross section of the driven disc 2 is a special-shaped equilateral triangle, along a cylindrical driving shaft 1 There are 3 clamping post holes 7 evenly arranged in the cross-section perpendicular to the axial direction; or as Figure 7 As shown, the cross-section of the driven disc 2 is a special-shaped square, and there are four clamping post holes 7 evenly arranged along a cross-section perpendicular to the axial direction of the cylindrical driving shaft 1; or as Figure 8 As shown, when the cross-section of the driven disc 2 is a special-shaped regular pentagon, there are five compression clamp holes 7 evenly arranged along a cross-section perpendicular to the axial direction of the cylindrical driving shaft 1; or as Figure 9 As shown, the cross section of the driven disc 2 is a special-shaped regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com