Planetary transmission system with bevel gears subjected to axial modification

A planetary transmission, helical gear technology, applied in the direction of gear transmission, transmission, components with teeth, etc., to achieve the effect of improving bearing capacity, reducing vibration and noise, and improving transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

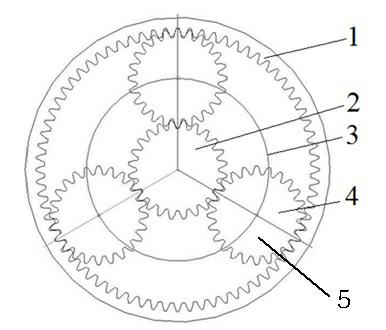

[0019] As shown in the figure, the helical gear planetary transmission system adopts tooth surface modification. The inner helical gear 1 and the outer helical gear 5 are both cylindrical gears. The axes of the inner helical gear 1 and the outer helical gear 5 are parallel to each other. The tooth direction and the axial direction of the external helical gear 5 form a certain angle. The external helical gear 5 includes a sun gear 2 and a planetary gear 4. There is 1 sun gear 2 and 1 to 6 planetary gears 4. The helical gear 1 forms a planetary gear train, the tooth surface of the external helical gear 5 is modified, and the internal helical gear 1 meshing with the external helical gear 5 is not modified.

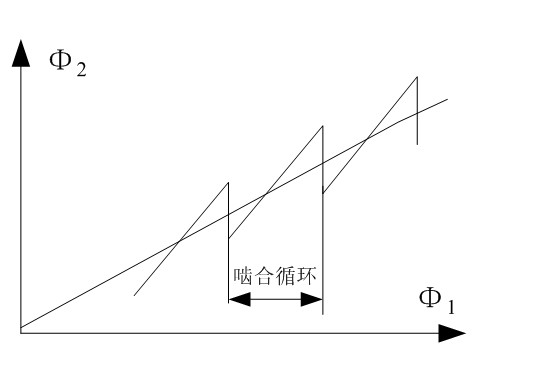

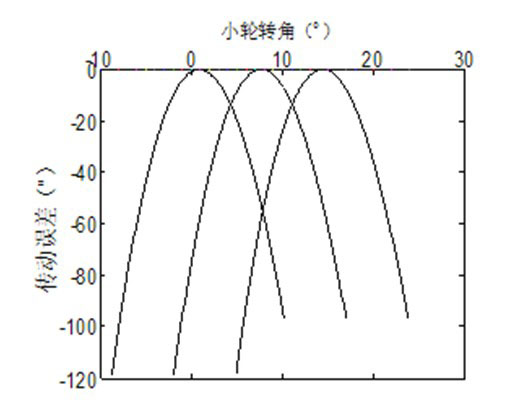

[0020] The invention proposes to preset the transmission error curve as a high-order transmission error curve, and improve the transmission performance through tooth surface modification.

[0021] The invention establishes the dynamic model of the modified helical gear tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com