Simple fixed-shaft type transmission assembly for loader

A gearbox and fixed-shaft technology, which is applied to mechanical equipment, engine components, engine seals, etc., can solve the problem of reducing the working efficiency and service life of the gearbox, wear of the primary worm gear and secondary worm gear, and force converter movement Vibration and other problems to achieve the effect of prolonging the interval between out-of-box maintenance, solving vibration and shock, and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

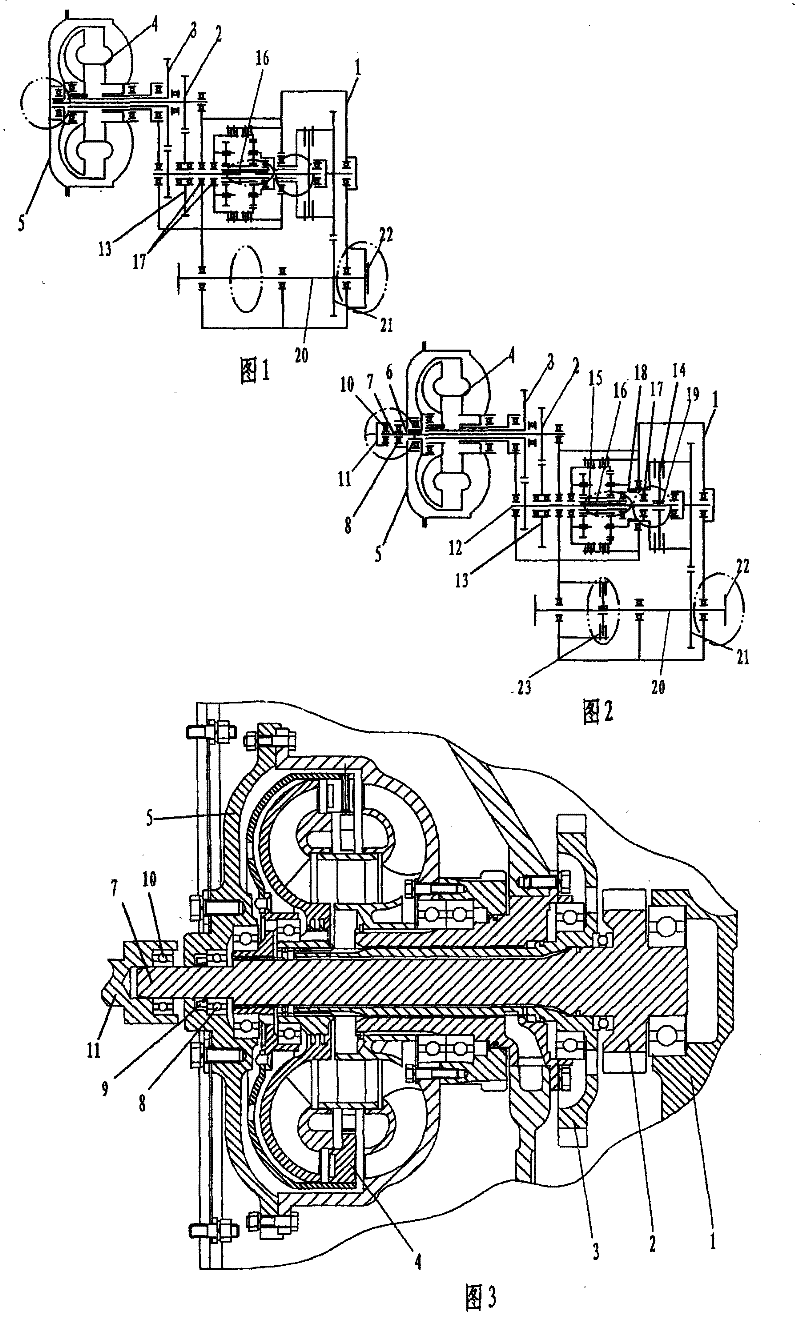

[0014] pass figure 1 with figure 2 It can be seen from the comparison that the simple fixed axis loader gearbox assembly of the present invention mainly has five improvements to the original loader gearbox assembly (outlined by the ellipse with double dotted line in the figure): 1. The through hole in the middle of the cover wheel and the forward cylindrical section of the input first-stage gear; 2. The middle part of the second shaft; 3. The right part of the 2nd shaft; 4. The middle left part of the 3rd shaft; 5. The third shaft at the right end.

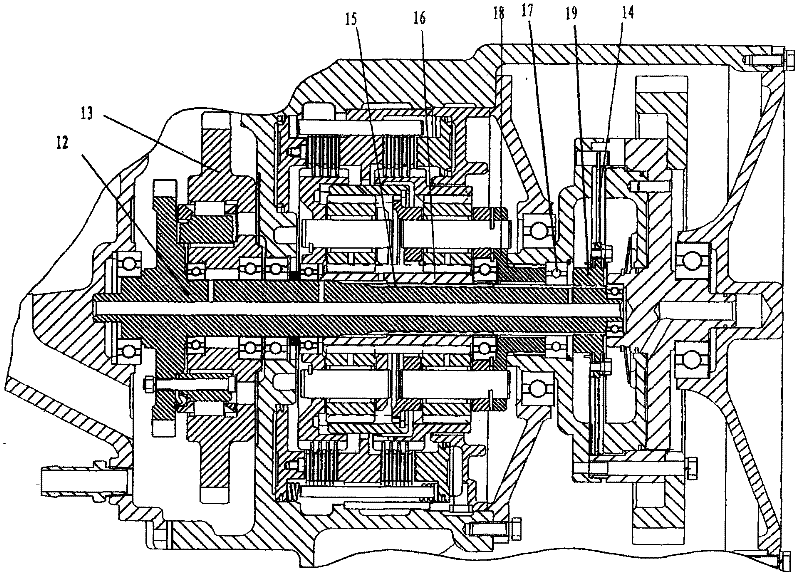

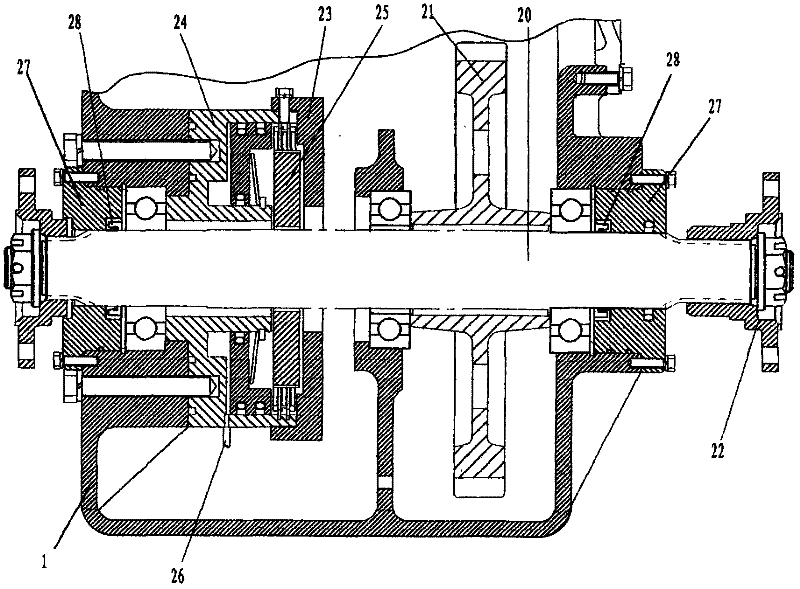

[0015] Refer to attached figure 2 with 3 , In the gearbox housing 1 of the present invention, one shaft, two shafts and three shafts are also installed. The first shaft is also the gear shaft of the input primary gear 2 and the input secondary gear 3, the input primary gear 2 is a solid shaft, the input secondary gear 3 is a hollow shaft, and the input secondary gear shaft is set outside the input primary gear shaft , the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com