Rotary regulating-and-controlling-type water purification tap

A technology of rotary joints and faucets, which is applied in the field of faucets, can solve the problems of increasing the production process of clean faucets, poor sealing performance, and reducing production efficiency, so as to reduce manual assembly costs, improve axial limit stability, and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

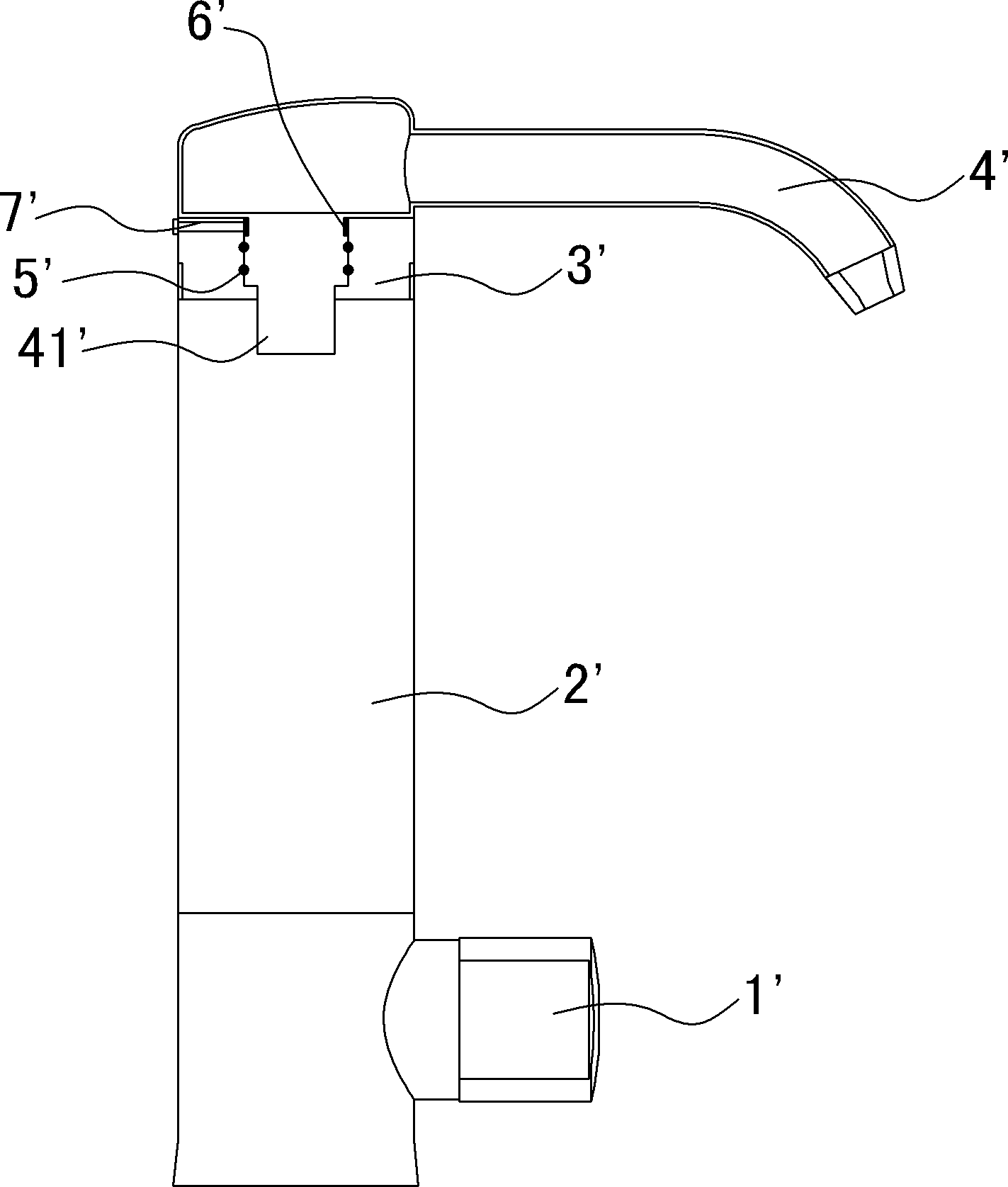

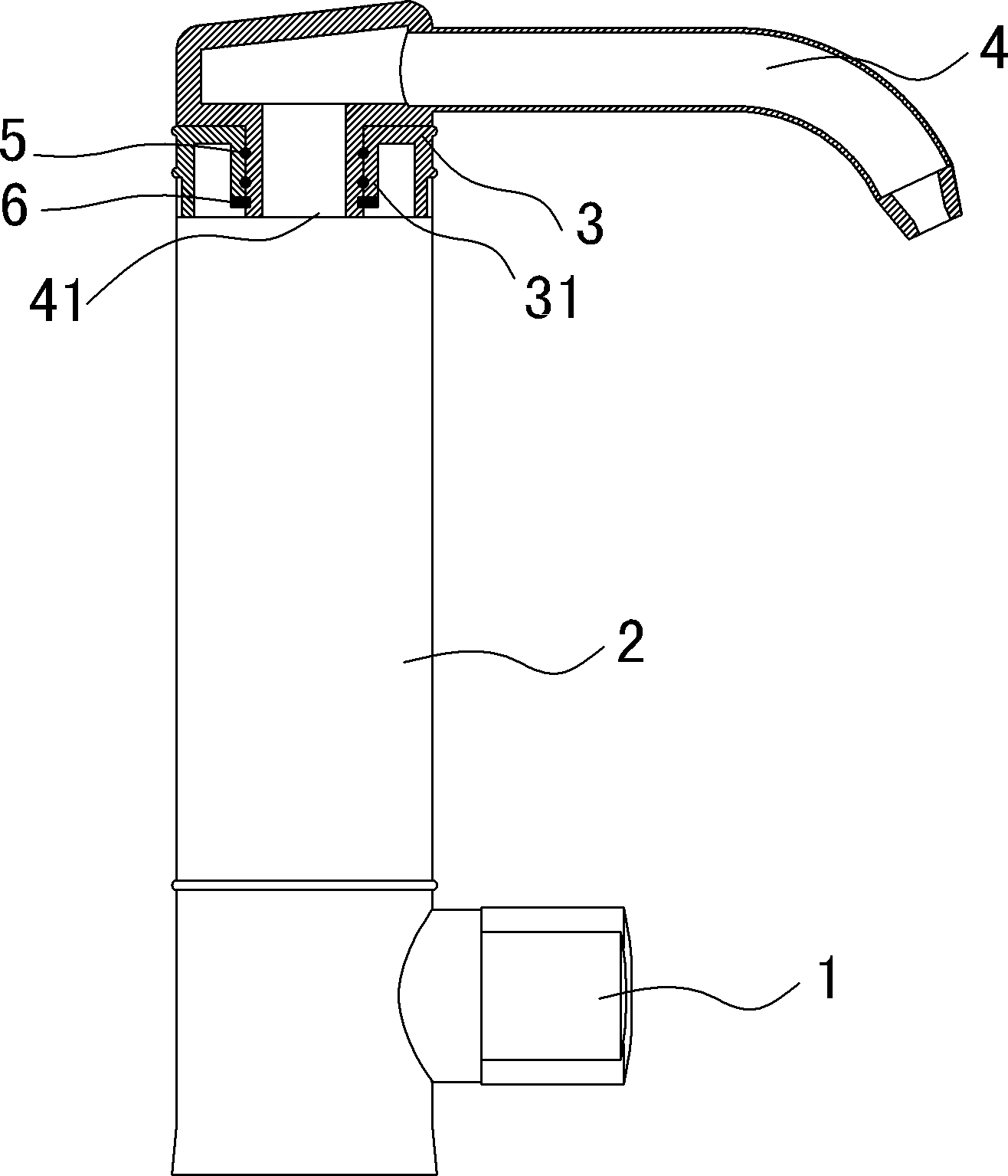

[0018] refer to figure 2 , this embodiment discloses a rotary control type water purification faucet, including a faucet body 1, a water purification pipe body 2, a rotating centering 3 and a water outlet pipe 4, and the water purification pipe body 2 is arranged on the water outlet of the faucet body 1 The rotating centering 3 is set on the water outlet of the water purification pipe body 2, and one end of the water outlet pipe 4 is provided with a rotary joint 41, and the outer wall of the rotary joint 41 is provided with two intervals from top to bottom. O-shaped sealing ring 5, two O-shaped sealing rings 5 play the effect of sealing water, and described outlet pipe 4 is rotatably arranged on the rotation centering 3 through the rotary joint 41 thereon, in order to make outlet pipe 4 longitudinally be fixed but It is still rotatable in the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com