High-temperature and high-pressure sleeve type compensator

A high-temperature and high-pressure, sleeve-type technology, which is used in expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve the problems of pipeline compensator leakage, seal damage, and excessive friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

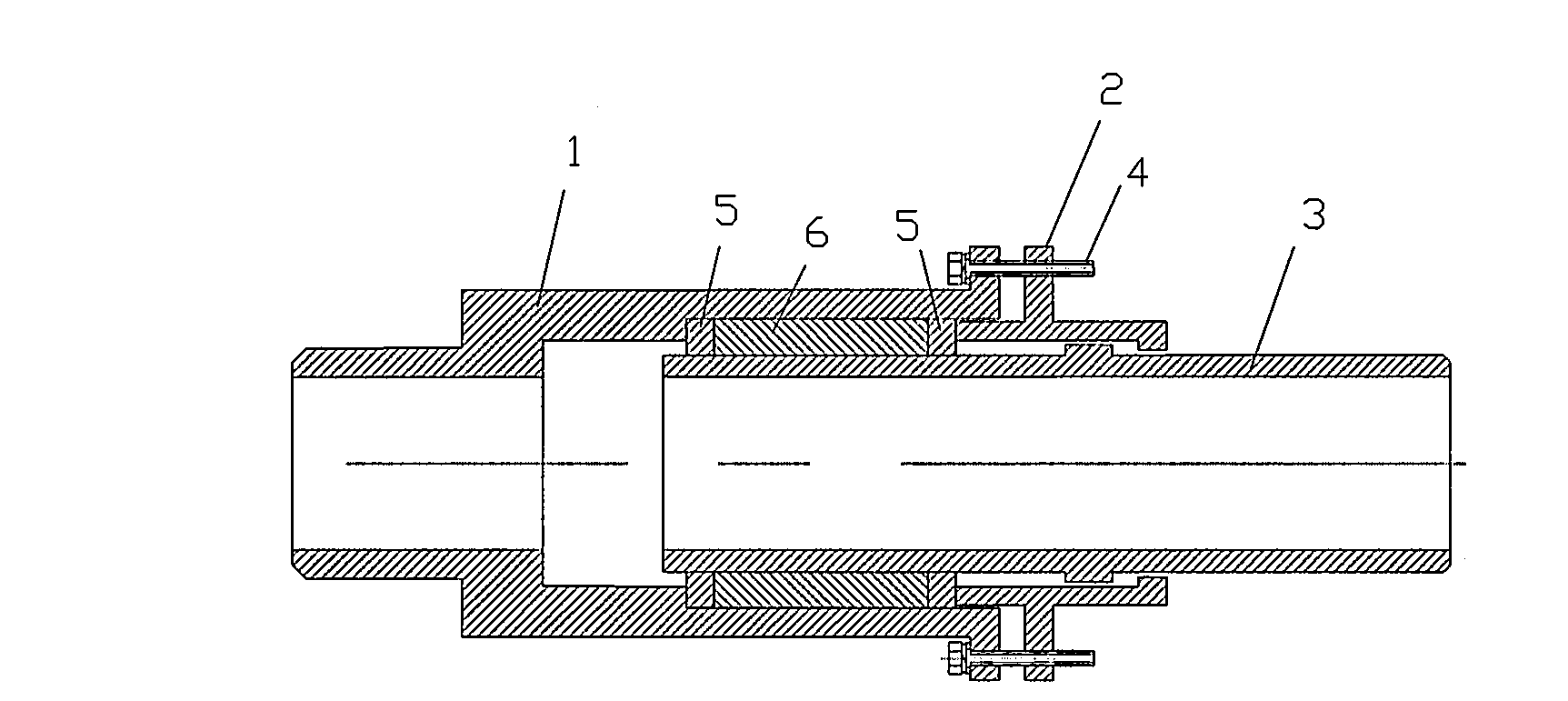

[0016] figure 1 It is a schematic diagram of the overall structure of the high temperature and high pressure sleeve type compensator in the embodiment of the present invention;

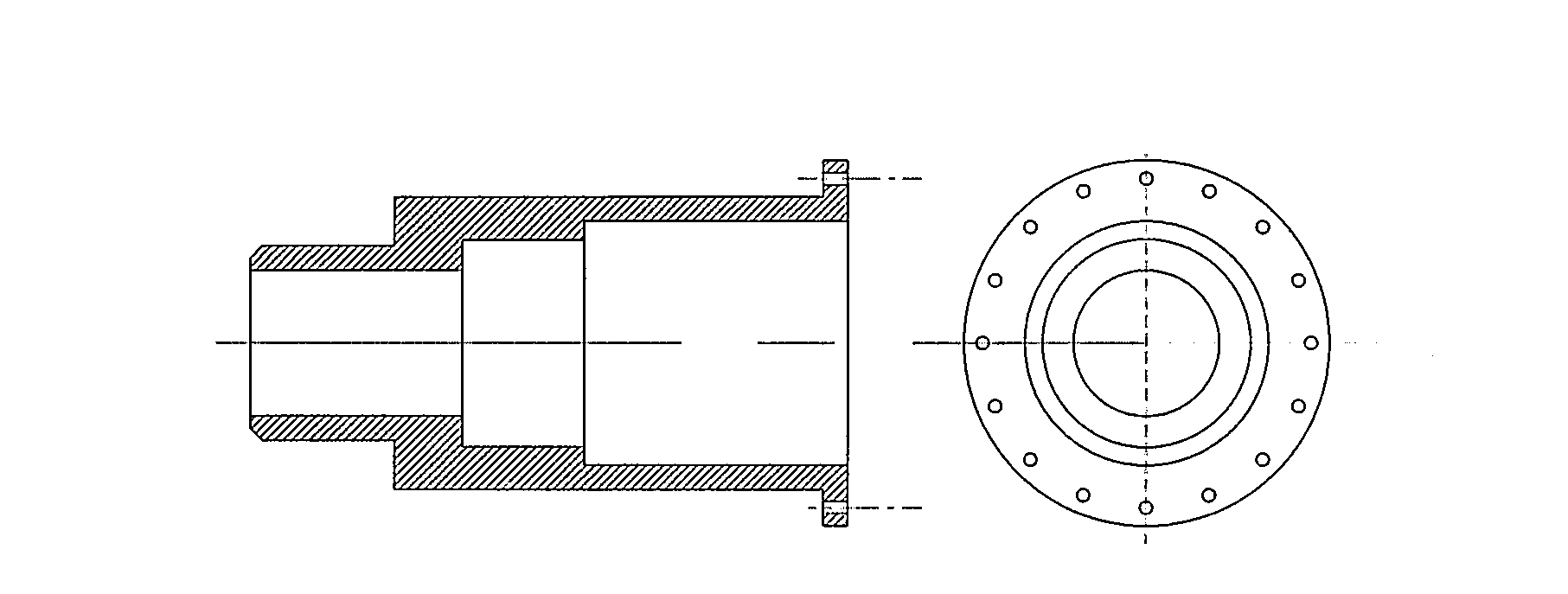

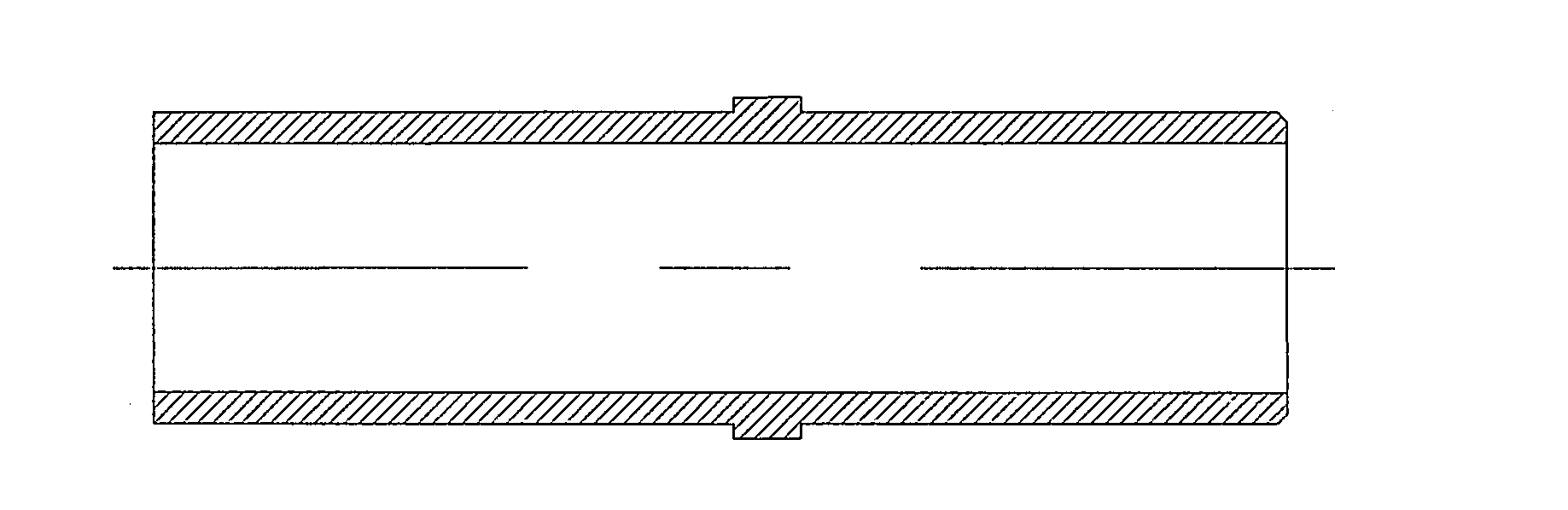

[0017] A high-temperature and high-pressure sleeve type compensator is composed of an outer sleeve 1, an outer pressure tube 2, an inner sleeve 3, a compression bolt 4, a sliding bearing compression ring 5 with self-lubricating properties, and a sealing packing 6. The inner diameter of the outer sleeve 1 is stepped, and there are 3 steps in total, which increase successively from left to right. The outer surface of the middle section of the inner sleeve 3 is provided with a ring-shaped outer convex ring as an anti-detachment shackle, and two self-lubricating features. The sliding bearing pressure ring 5 is set on the outer surface of the inner sleeve 3 on the left side of the ring-shaped outer convex ring, and inserted into the right end of the outer sleeve 1, and the sliding bearing pressure ring 5 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com