Backlight module, back plate and liquid crystal display device

A backlight module and backplane technology, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve problems such as poor versatility, high production cost, and difficulty in adapting to PCB boards, and reduce production costs. and processing cost, high versatility, and the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

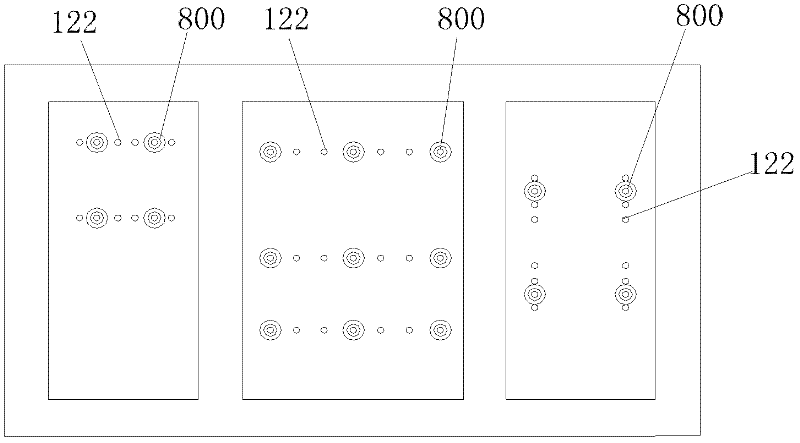

[0025] The present invention provides a liquid crystal display device, including a liquid crystal panel and a backlight module, the bottom of the backlight module is provided with a back plate, and the back plate is processed by one board or a plurality of boards or a plurality of boards of different materials Formed, on the board surface of the backboard, there is provided a chute for fixing the convex hull. For this scheme, the present invention is further illustrated by the following preferred embodiments:

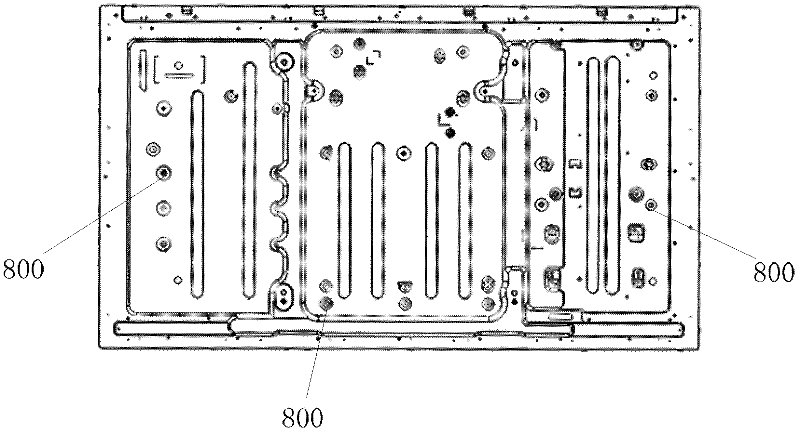

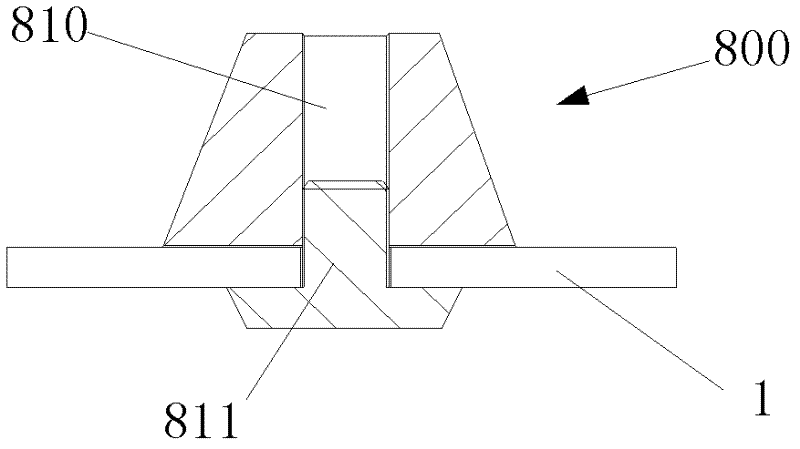

[0026] like figure 2 Shown is a backplane processed from a whole board, on which a chute 121 is arranged, the length, position and quantity of the chute 121 are correspondingly set on the backplane according to PCBs of various sizes and specifications. On the surface of the board, a convex hull 800 is provided on the chute 121. The convex hull 800 is installed on the chute 121 as a separate part, and its position can be adjusted according to the size of the PCB. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com