Fresnel lens and lamp with same

A Fresnel lens and lens technology, applied in the field of Fresnel lenses and lamps using the Fresnel lens, can solve the problems of increasing the difficulty of installation design, the large space occupied by the lens, and the consumption of manufacturing materials, etc., to achieve the goal of lamps Effects of volume reduction, cost reduction, lens volume reduction and space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

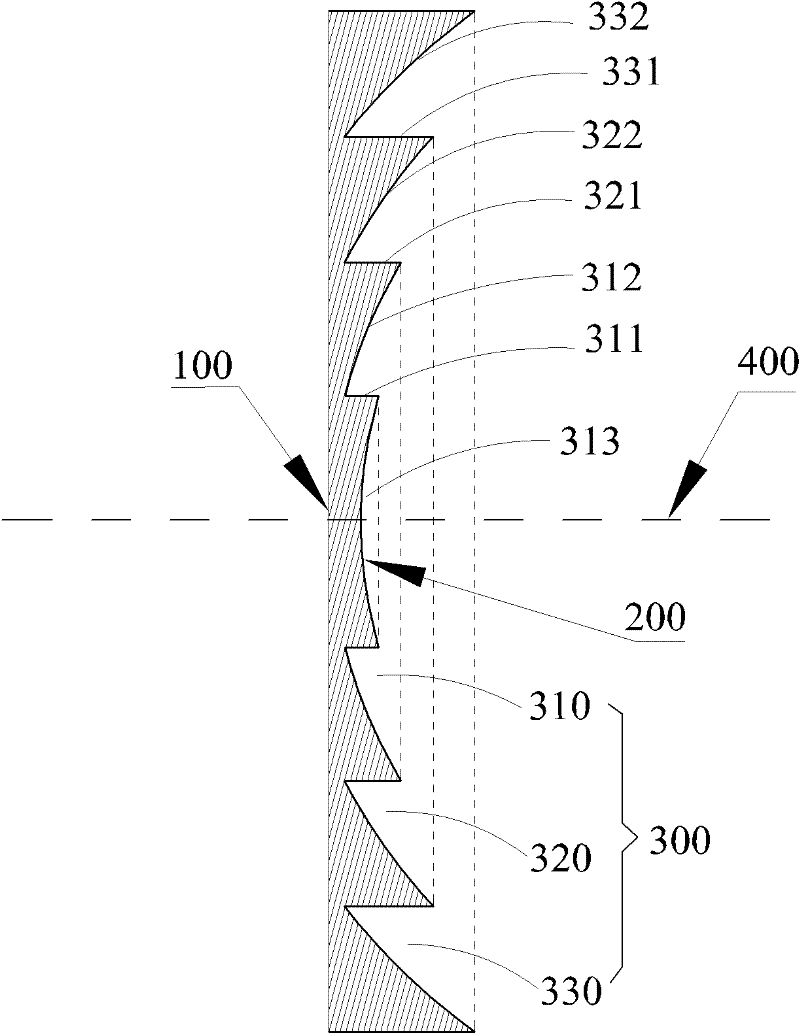

[0024] The Fresnel lens includes an incident surface and a refraction concave surface opposite to the incident surface. The refraction concave surface is divided by a plurality of concentric ring grooves. The outer sidewall of the shaft, the inner sidewall of the annular groove are perpendicular to the incident surface, and the outer sidewall of the annular groove is inclined towards the optical axis of the lens. The radius of curvature of the outer wall of the circular groove increases successively with a fixed value.

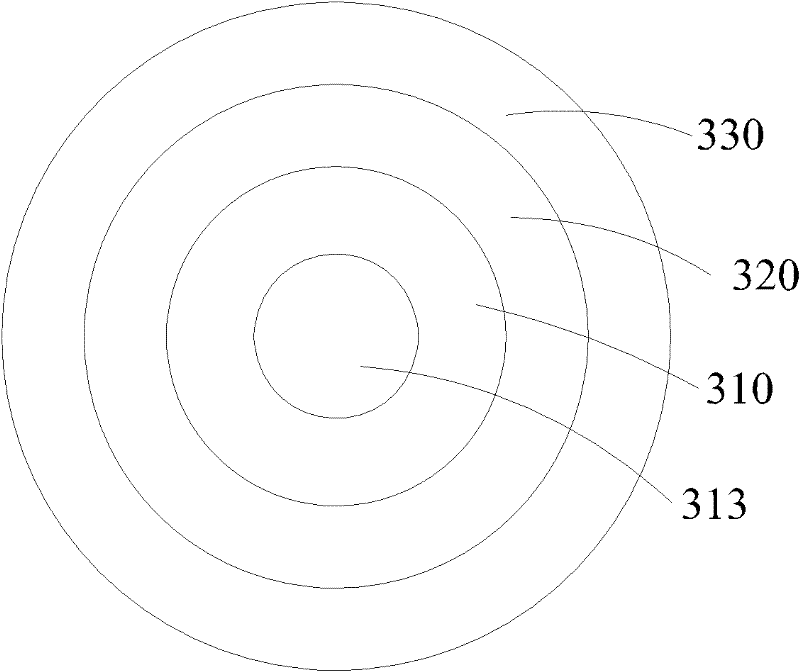

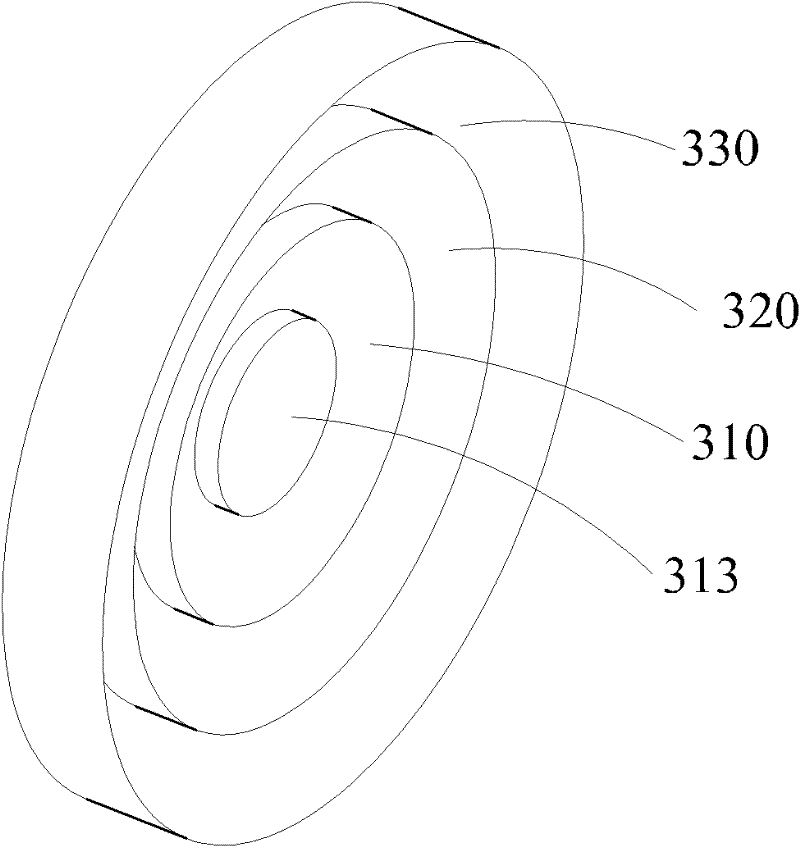

[0025] figure 1 It is an axial sectional view of the Fresnel lens structure in one embodiment. figure 2 is a rear view of the Fresnel lens structure in one embodiment. image 3 is a side view of the Fresnel lens structure in one embodiment.

[0026] to combine Figure 1 to Figure 3 , the Fresnel lens inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com