Anti-glare lens

An anti-glare and lens technology, which is applied to lighting devices, components of lighting devices, refractors, etc., can solve problems such as visual fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

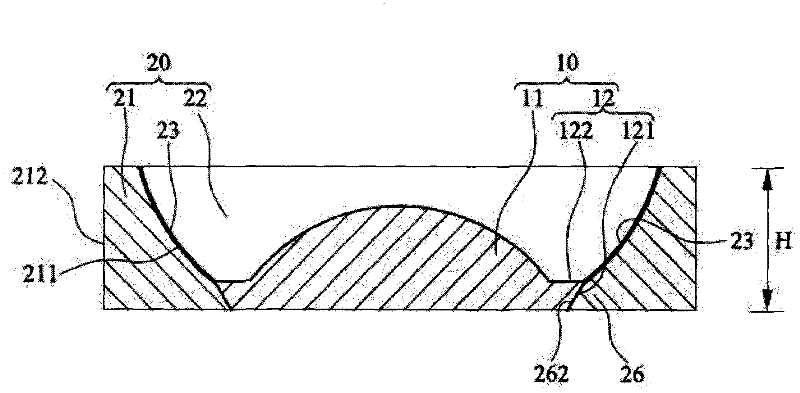

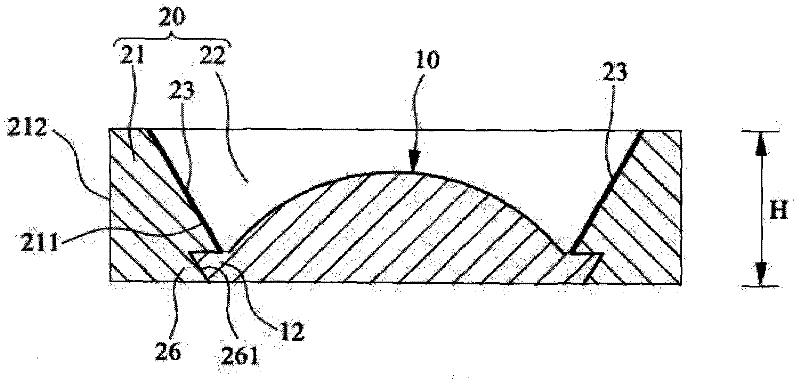

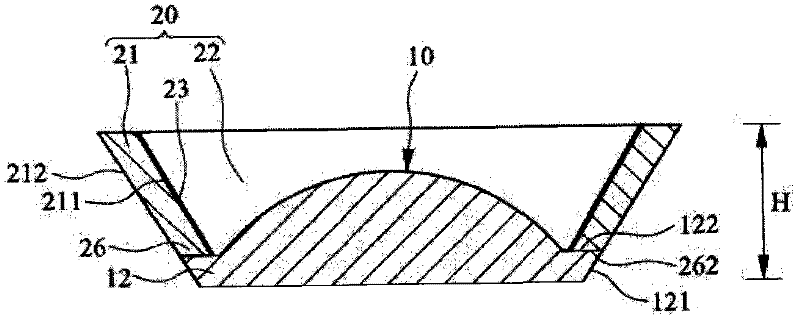

[0018] see Figure 1 to Figure 10 As shown, the present invention is an anti-glare lens, which includes a lens 10 and a frame body 20; the lens 10 includes a lens portion 11, and a bonding portion 12 combined with the periphery of the lens portion 11; the frame body 20 It includes a side wall structure 21 combined with the lens 10, and a hollow groove 22 surrounded by the side wall structure 21 for the lens part 11 to be exposed, and at least one anti-glare is provided on the wall surface of the side wall structure 22 Area 23; the side wall structure 21 is equipped with a corresponding joint portion 26 correspondingly combined with the joint portion 12 for the frame body 20 to be combined with the lens 10, so that after the light passes through the lens portion 11 of the present invention, Part of the light refracted from the peripheral side of the lens portion 11 can be uniformed by the anti-glare area 23 of the side wall structure 22 to reduce the glare caused by the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com