Steam generator

A technology of steam generator and evaporation box, which is applied in steam generation, steam generation device, lighting and heating equipment, etc. It can solve the problem of not being able to provide steam in time, and achieve improved steam production efficiency, increased evaporation efficiency, and large heat exchange area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

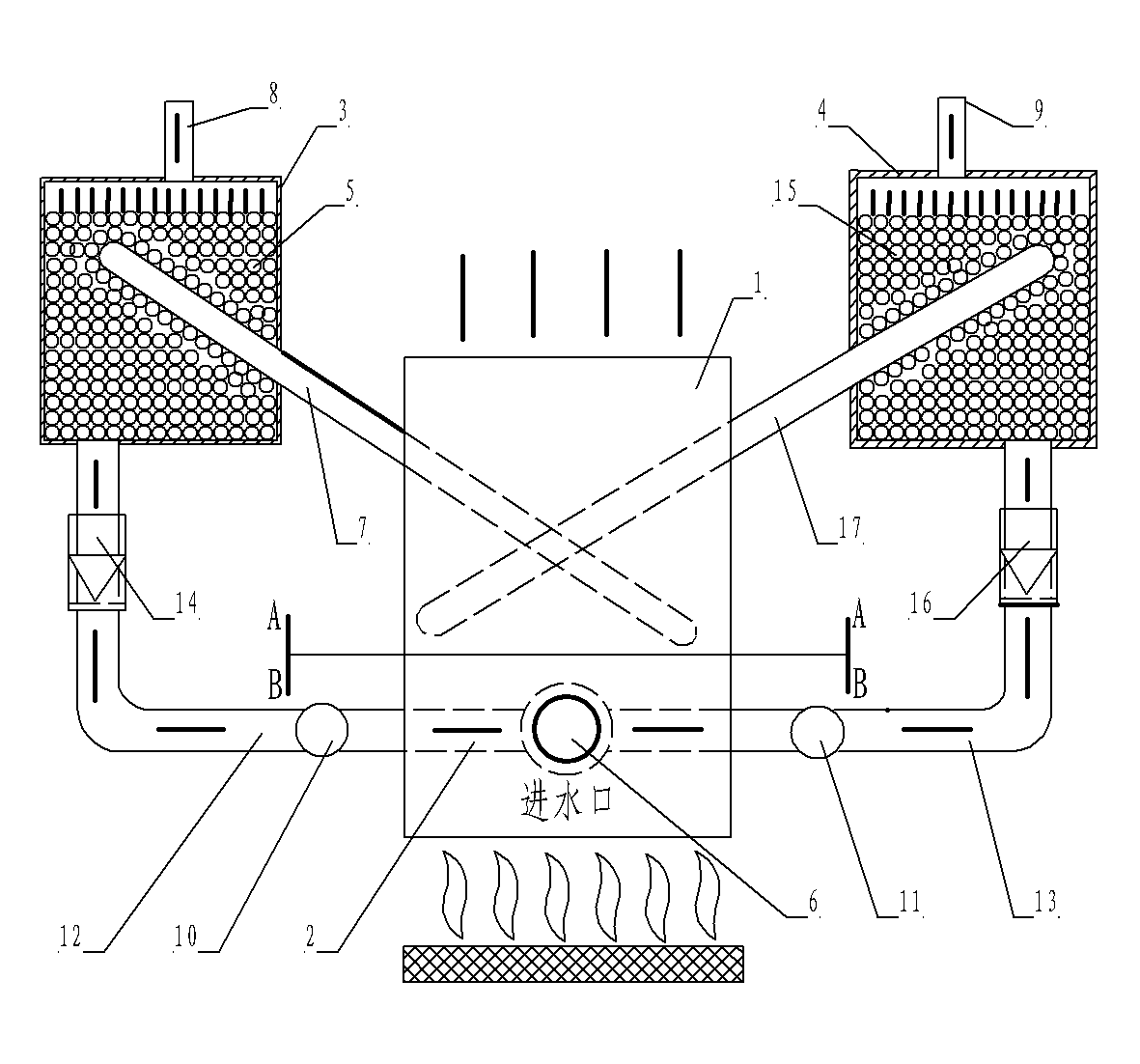

[0014] Below in conjunction with accompanying drawing example, the present invention is described in further detail:

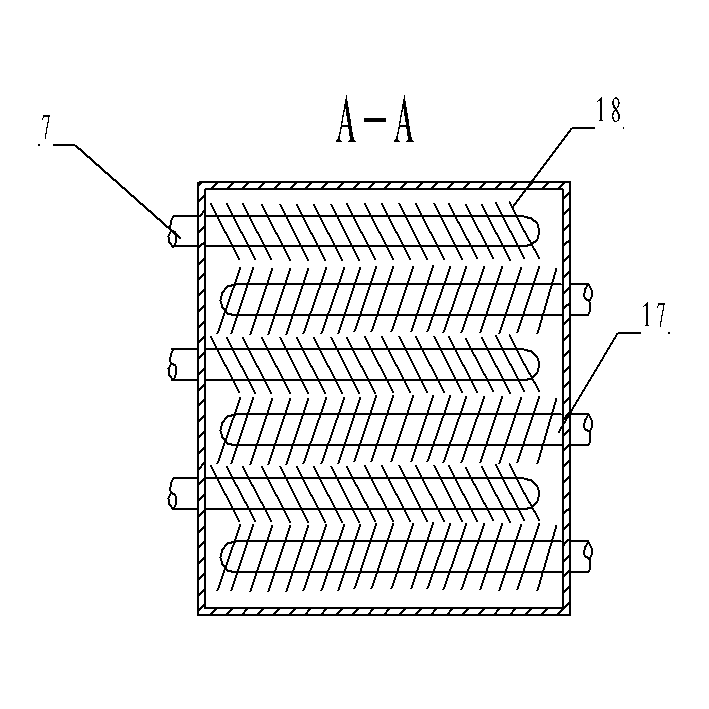

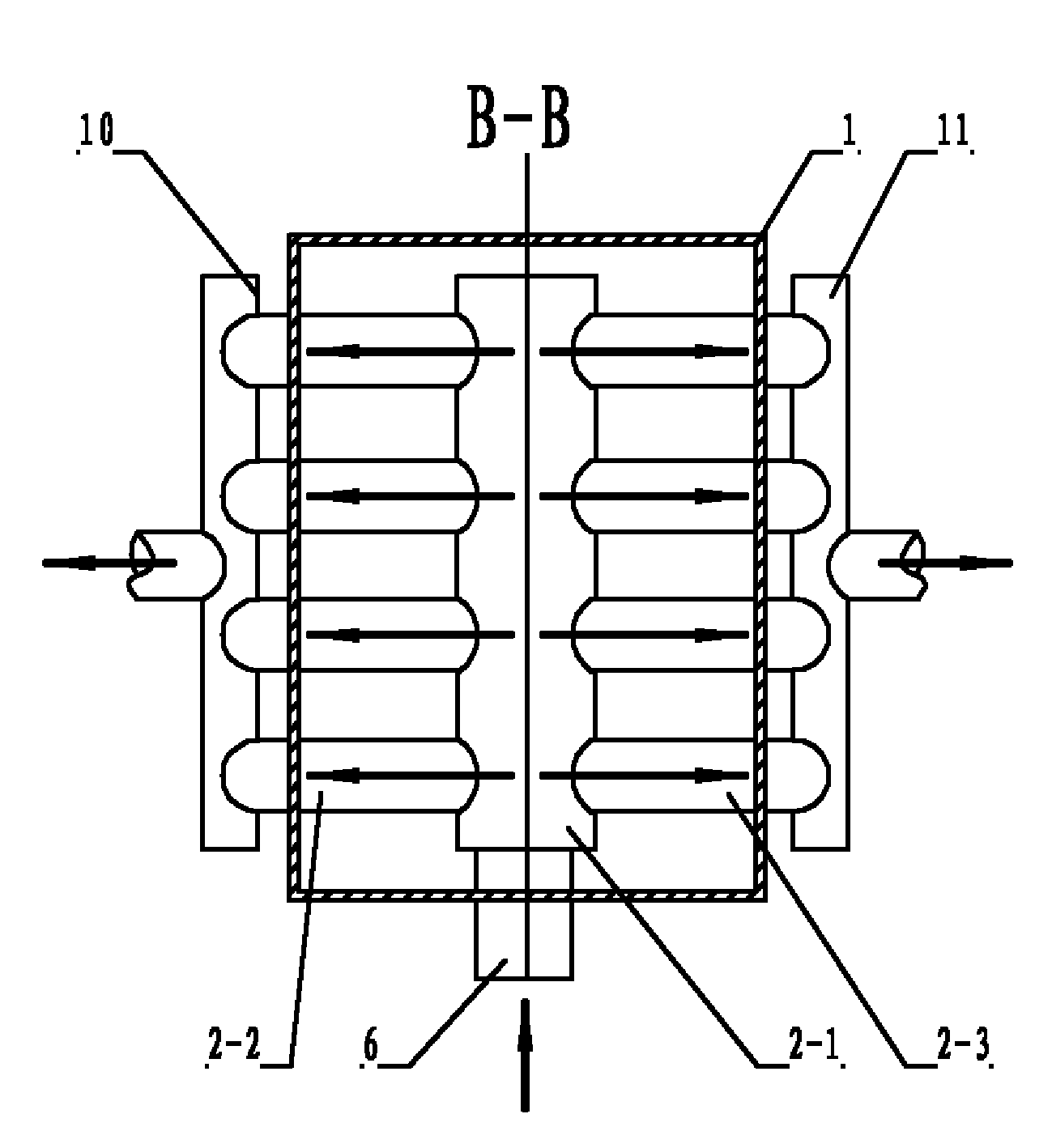

[0015] Such as figure 1 The present embodiment shown, it comprises the heat collecting cylinder 1 that has two openings, and the inner lower part of heat collecting cylinder 1 is equipped with tubular heat exchanger 2, and this tubular heat exchanger 2 protrudes from both sides of heat collecting cylinder 1 The two ends of the tubular heat exchanger 2 protruding from the heat collecting tube 1 are respectively connected with an evaporation box 3, 4. Many copper balls 5, 15 with good thermal conductivity are installed in the evaporation box 3 and the evaporation box 4. Type heat exchanger 1 communicates with water inlet pipe 6; 6 heat pipes 7, 17 are installed in the upper part of heat collecting tube 1, and heat pipes 7, 17 are both closed pipes at both ends and heat transfer pipes enclosed in the pipes. The composition of the working medium, this kind of hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com