Heat tube type all-glass vacuum solar collector tube

An all-glass, heat-collecting tube technology, applied in solar collectors, solar thermal devices, solar thermal energy, etc., can solve problems such as low compressive strength, reduced thermal efficiency, and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

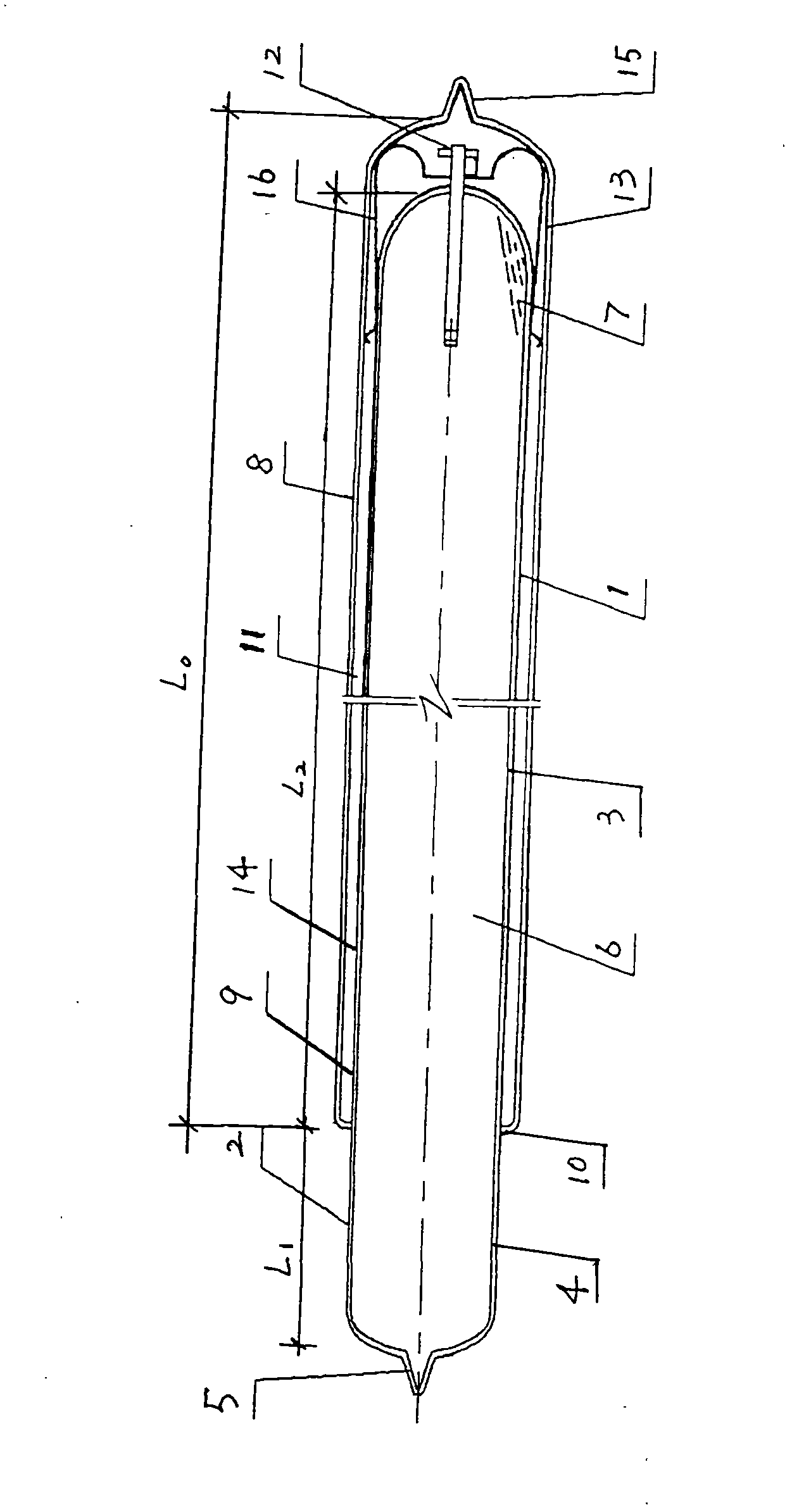

[0019] according to figure 1 As shown in the structure, the heat pipe type all-glass vacuum solar heat collector has a length L. 1800mm, the outer diameter of the cover glass tube 8 is 58mm, the wall thickness is 1.8mm, the outer diameter of the inner glass tube 9 is 47mm, and the wall thickness is 2.6mm, the outer extension length L of the inner glass tube 9 1 ——that is, the length of the condensation section 4 is 100 mm, the glass wall thickness of the heat-sealed end 5 is 1.8 mm, and the length of the evaporation section 3 is L 2 is 1770mm; the total volume of the vacuum chamber 6 is V 1 2566cm 3 , the heat transfer medium 7 is distilled water, and its liquid phase volume is V 2 5.1ml, the volume ratio between the two is V 2 / V 1 = 0.2%.

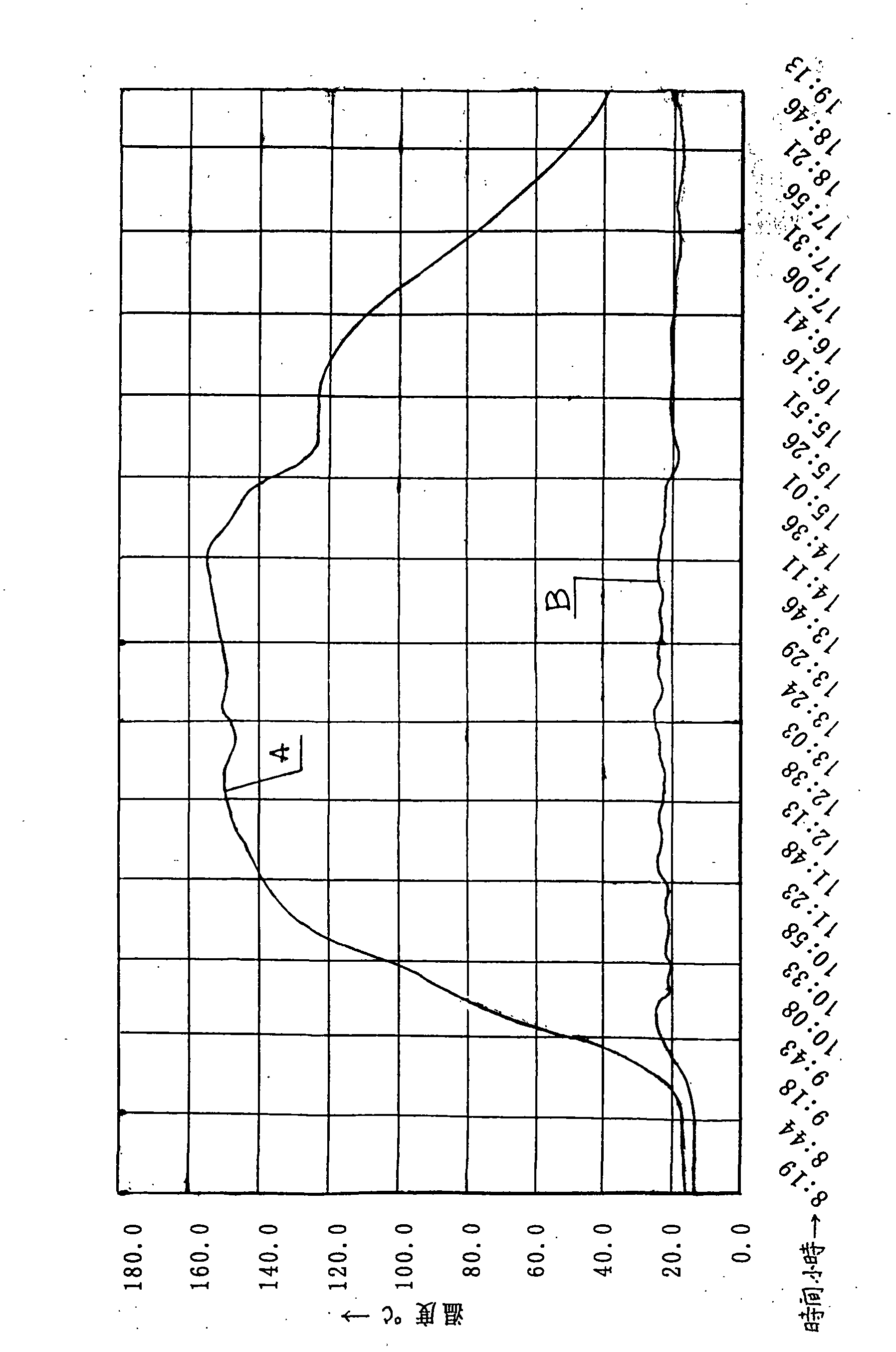

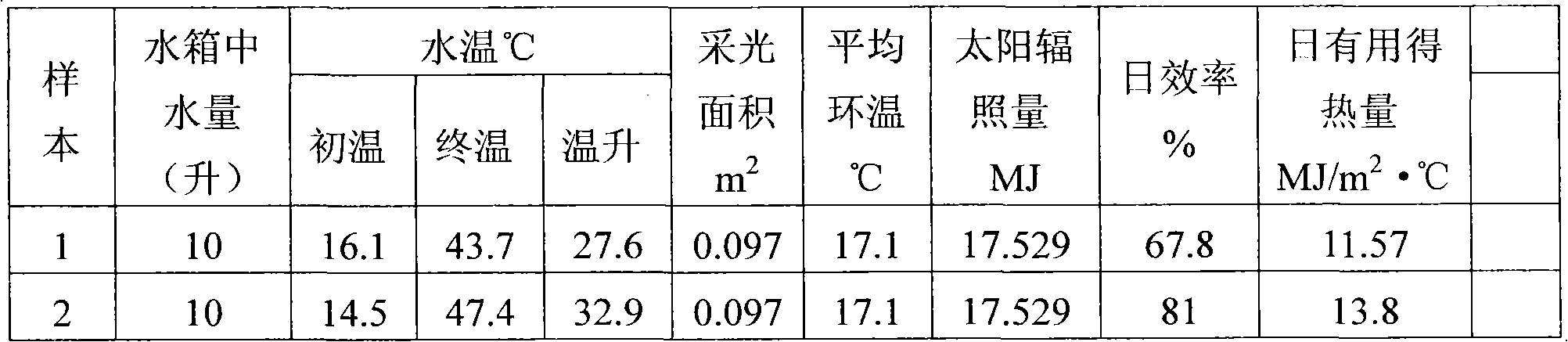

[0020] As shown in Table 1, it is the condensing section 4 of the single heat pipe type all-glass vacuum solar collector tube of embodiment 1 inserted in the test water tank of 10 liters of water, and the thermal performance test re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com