Air-conditioning heat exchanger using mixed refrigerant and air conditioner

A technology of mixing refrigerants and heat exchangers, applied in refrigerators, refrigeration components, household heating and other directions, can solve the problem of high requirements for diversion, and achieve the effect of improving heat exchange efficiency, improving heat exchanger efficiency and uniform diversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

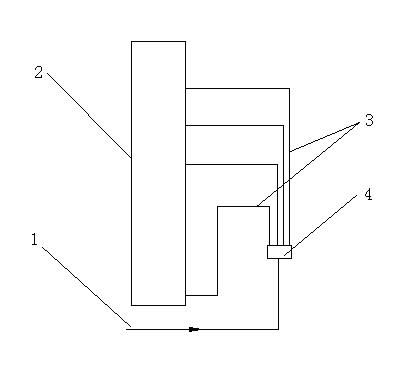

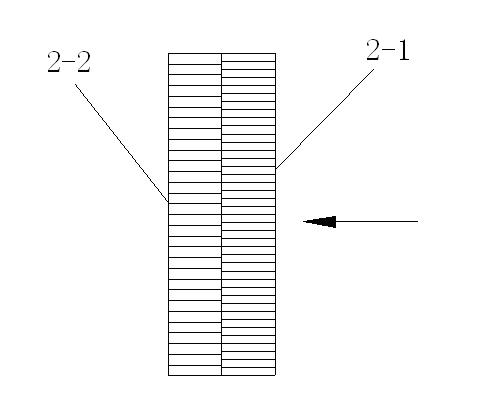

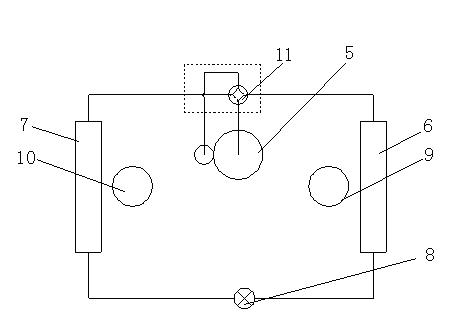

[0025] see Figure 1-Figure 2 , an embodiment of an air-conditioning heat exchanger using a mixed refrigerant in the present invention, including a finned tube heat exchanger 2, a header 1, at least two branch pipes 3, and connections between the header 1 and each branch pipe 3 A flow divider 4, the manifold 1 is connected to the inlet end of the flow divider 4, and the flow diversion outlets of the flow divider 4 are respectively connected to one end of each of the flow divider pipes 3, and the other ends of the flow divider pipes 3 are respectively It is connected with the pipeline on the finned tube heat exchanger 2, and the said distribution tubes 3 are placed vertically with the same length and inner diameter, and the size of the inner diameter of each distribution tube is 2.0-3.5mm.

[0026] The above-mentioned finned tube heat exchanger 2 adopts 7mm internally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com