Intelligent modularized boiler flue gas waste heat energy water heating device

A water heating device and boiler flue gas technology, applied in the fields of energy saving, emission reduction, and waste heat energy reuse, can solve the problems of inability to use heat exchange, etc., and achieve the effects of strong adaptability, improved heat exchange rate, and small volume of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

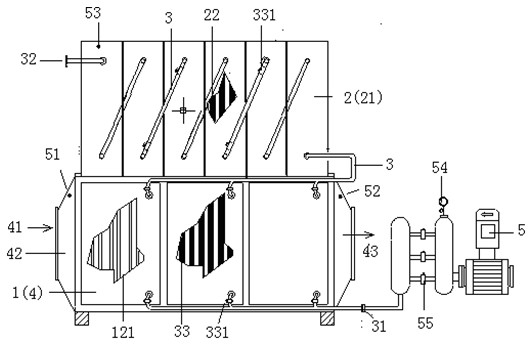

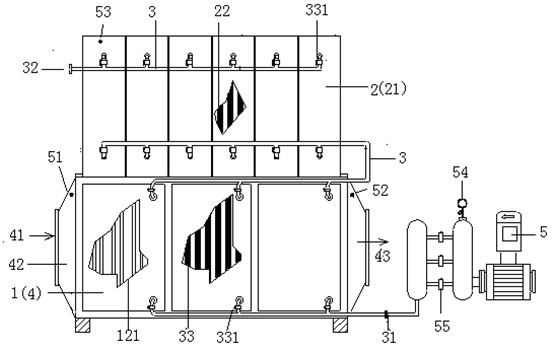

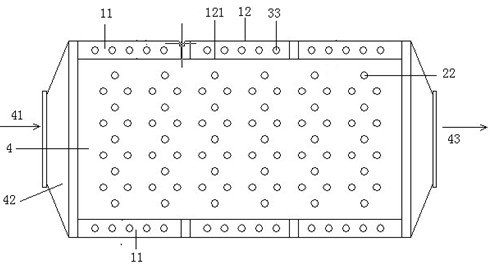

[0027] Such as figure 1 , 2 , as shown in 3,

[0028] The invention is mainly composed of an intelligent controller, a tubular heat exchanger, a clean water flow pipeline, a high-temperature flue gas channel and a water pump. The tubular heat exchanger 1 is composed of a number of single tubular heat exchange modules 11 with the same structure and uniform specifications (there are 6 blocks in two rows in the figure); the superconducting heat pipe heat exchanger 2 is composed of A plurality of single superconducting heat pipe modules 21 (6 in the figure) with the same structure and uniform specifications are combined. The clean water flow pipeline is arranged in modules in sections, and the modules are combined to form a through main pipeline 3 . The high-temperature flue gas channel 4 is located between two rows of single tubular heat exchange modules of the tubular heat exchanger, and penetrates through the combination of the single tubular heat exchanger modules; the low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com