Method of manufacturing temperature sensor

A technology of temperature sensor and manufacturing method, which is applied in thermometers, instruments, thermometers using electric/magnetic components directly sensitive to heat, etc. Guarantee and other issues, to achieve the effects of accurate measurement, improved measurement accuracy and sensitivity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

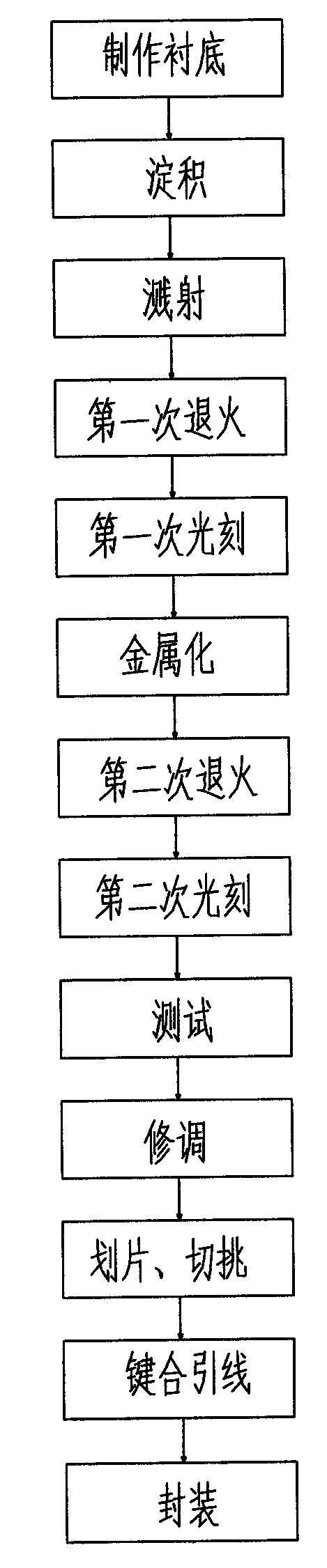

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] A method for manufacturing a temperature sensor, characterized in that it comprises the steps of:

[0025] 1) Making the substrate: choose a silicon wafer or sapphire, and then engrave a grid on the silicon wafer or sapphire to make a substrate. Compared with the existing ceramic substrate, it is easier to choose a silicon wafer or sapphire. At the same time, the production difficulty is low;

[0026] 2) Deposition: The substrate obtained in step 1) is cleaned with an acidic solution, and then a layer of insulating material is deposited on the surface of the substrate engraved with a grid to make a substrate. The purpose of depositing an insulating layer on the substrate is to avoid When sputtering platinum in one step, since the silicon wafer is a semiconductor, if there is no insulating layer, the platinum layer will conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com