Solenoid nesting type all-fiber current sensor

A solenoid and all-fiber technology, applied in voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems of optical fiber bending loss and large bending birefringence effect, and reduce bending loss and birefringence effect , flexible winding method, and the effect of reducing the size of the sensor head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in further detail below in conjunction with accompanying drawing:

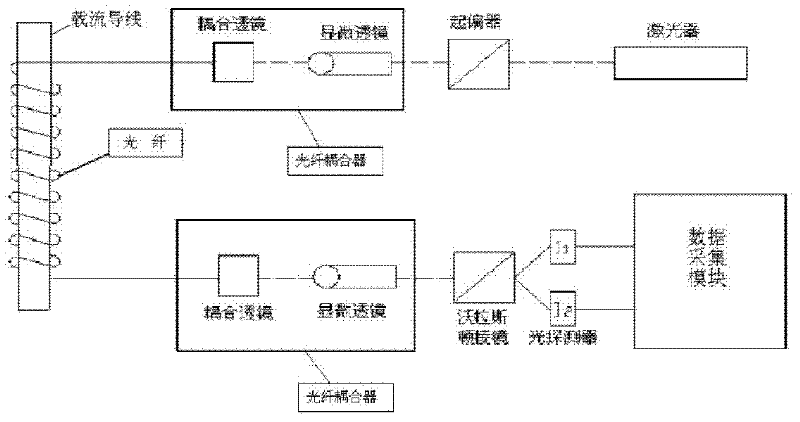

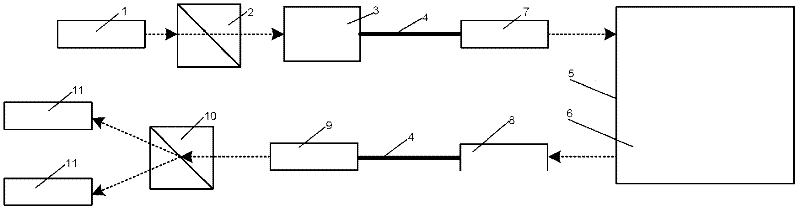

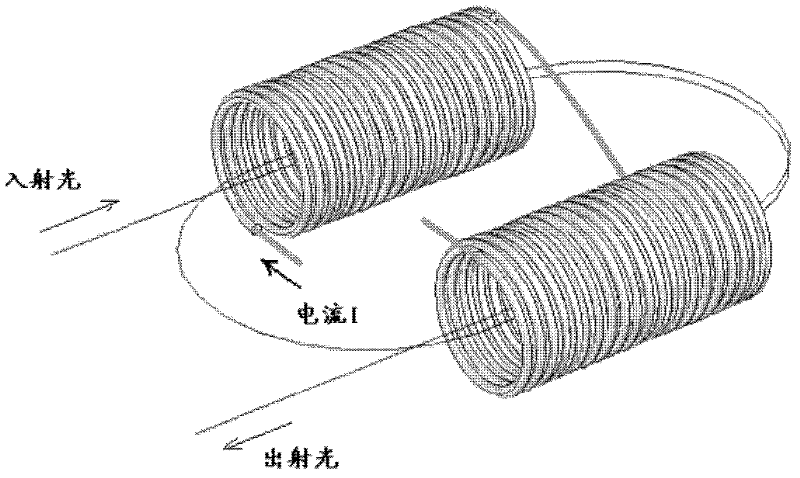

[0047] see Figure 4, when the traditional light-wound electric current sensor measures a small current, the magnetic field strength around the cable is very small. In order to increase the magnetic field generated by the measured current, the wire passing the measured current can be wound into a solenoid form, so that the solenoid The internal magnetic field will increase many times (related to the number of wire turns per unit length). The sensing fiber is located on the axis of the solenoid, so that the sensing fiber passes through the coil multiple times and also wraps around to form a solenoid structure, so that the Faraday rotation angle will be doubled. It is also possible to connect several solenoids in series, and the optical fibers pass through them sequentially to make the structure more symmetrical and compact. However, it should be noted that the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com