Performance testing instrument for thermoelectric electromagnetic valve

A solenoid valve and thermoelectric technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., to achieve the effects of wide application range, convenient operation and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

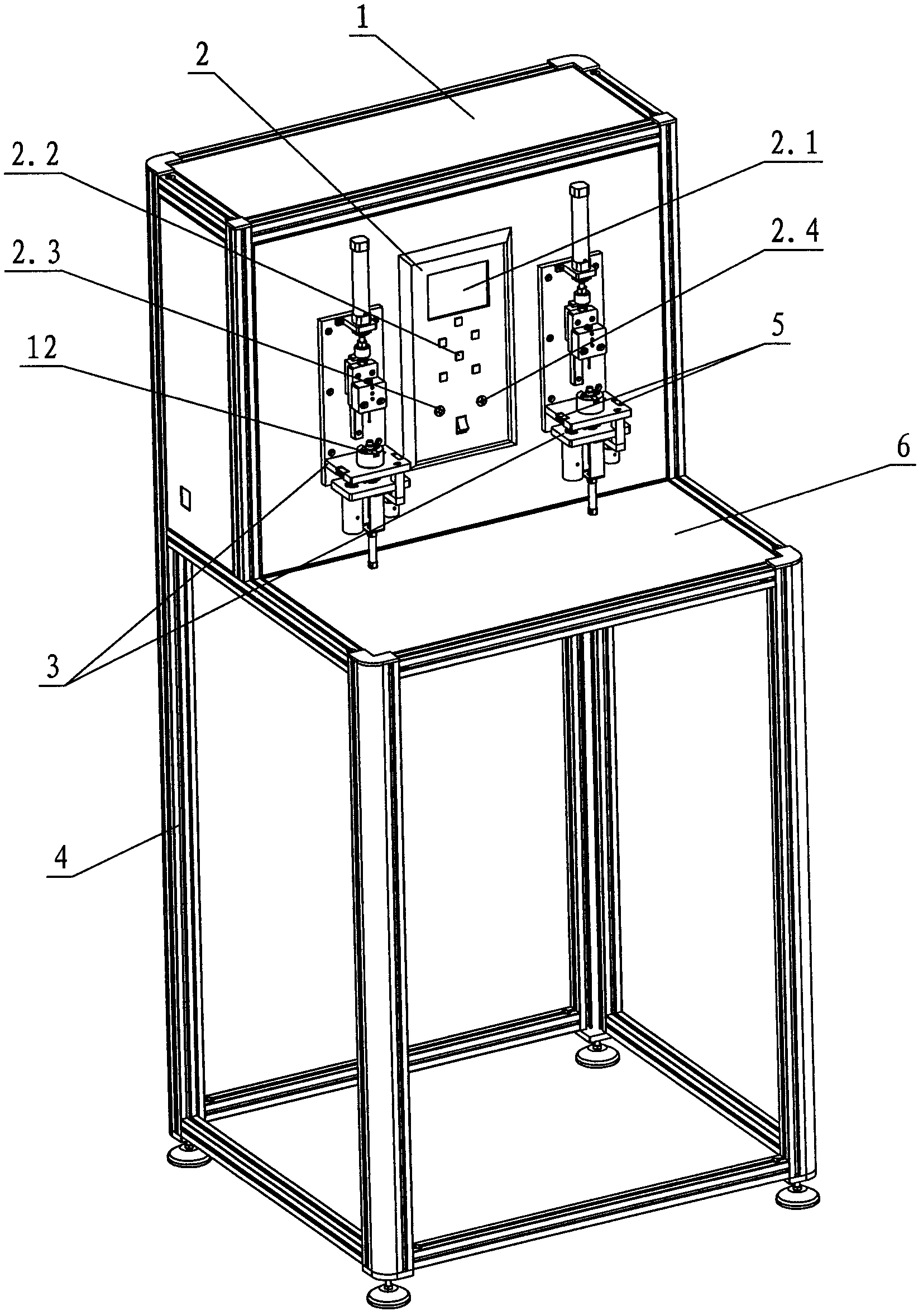

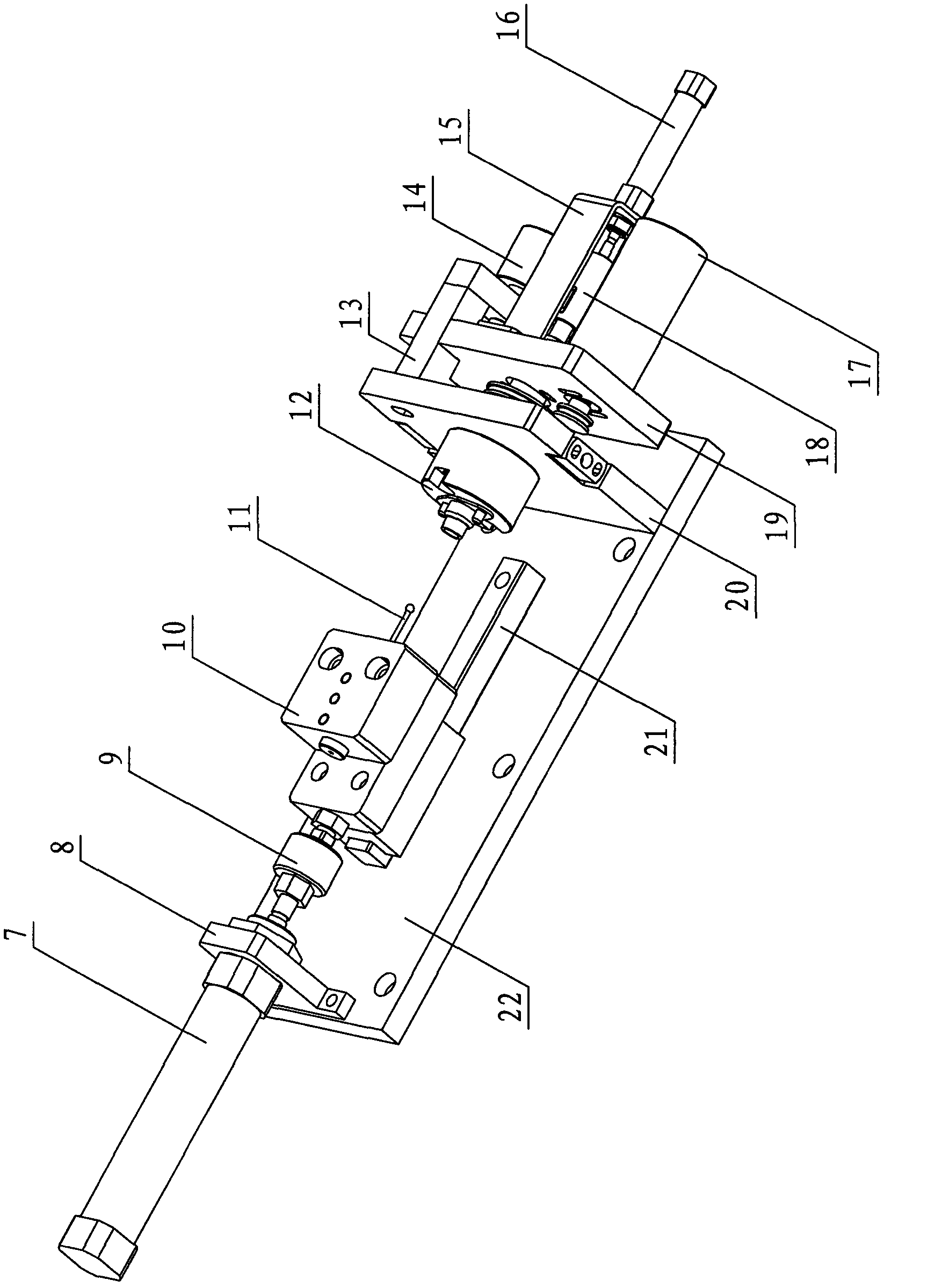

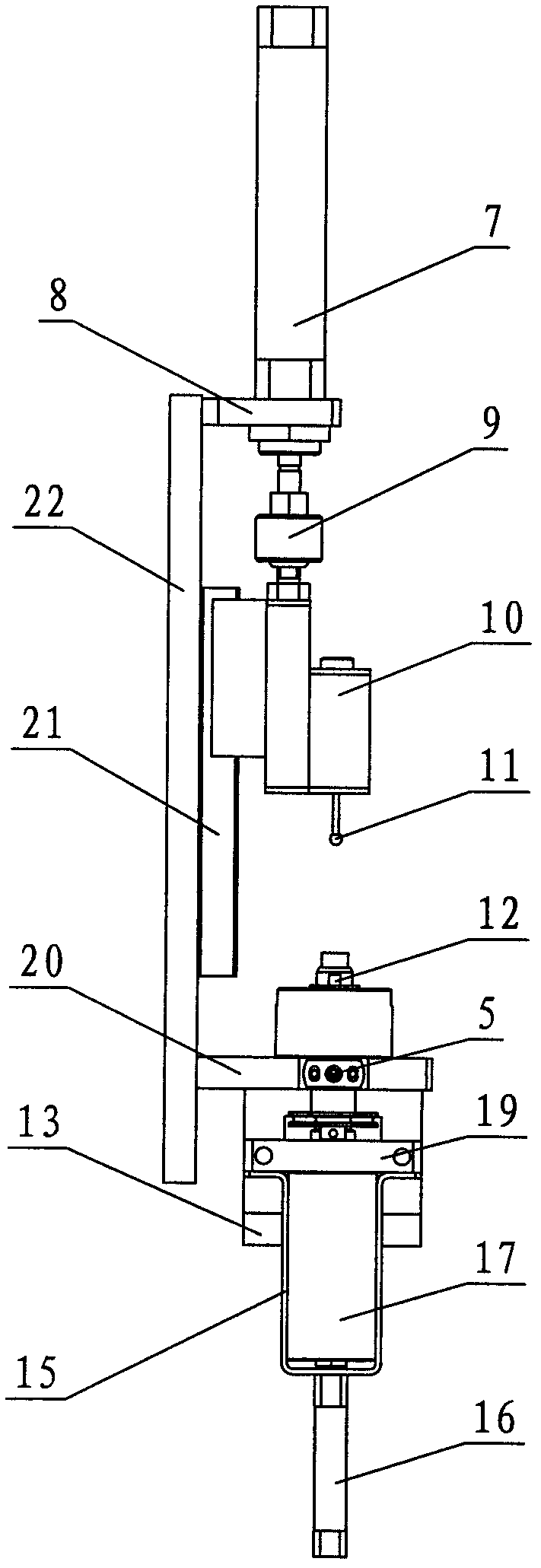

[0022] see Figure 1-Figure 5 , The thermoelectric solenoid valve performance tester includes a chassis 1, a control panel 2 and two solenoid valve fixtures 3 are arranged on the surface of the chassis, and a solenoid valve detection circuit and a solenoid valve fixture control circuit are arranged in the chassis. The solenoid valve detection circuit includes the main control MCU, the constant current source part that generates the current required for the test, the voltage measurement module that tests the voltage at both ends of the solenoid valve, and the infrared contrast judgment circuit part that judges the opening and closing of the solenoid valve. The control panel 2 is provided with man-machine interface, main winding output port 2.3 and auxiliary winding output port 2.4; man-machine interface includes display screen 2.1 and keyboard 2.2, display screen, keyboard, solenoid valve fixture control circuit, constant current source part, voltage measurement The module, the...

no. 2 example

[0033] see Figure 6 and Figure 7 , this thermoelectric solenoid valve performance tester includes a chassis 1', a control panel 2' is arranged on the surface of the chassis, and a solenoid valve detection circuit is arranged in the chassis; The constant current source part, the voltage measurement module for testing the voltage at both ends of the solenoid valve, and the infrared contrast judgment circuit part for judging the opening and closing of the solenoid valve.

[0034] The control panel 2' is equipped with man-machine interface, main winding output port 2.3' and auxiliary winding output port 2.4'; man-machine interface includes display screen 2.1' and keyboard 2.2', display screen, keyboard, solenoid valve fixture control circuit, constant current The source part, the voltage measurement module and the infrared shooting judging circuit part are respectively electrically connected with the main control MCU. The surface of the casing 1' is also provided with a handle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com