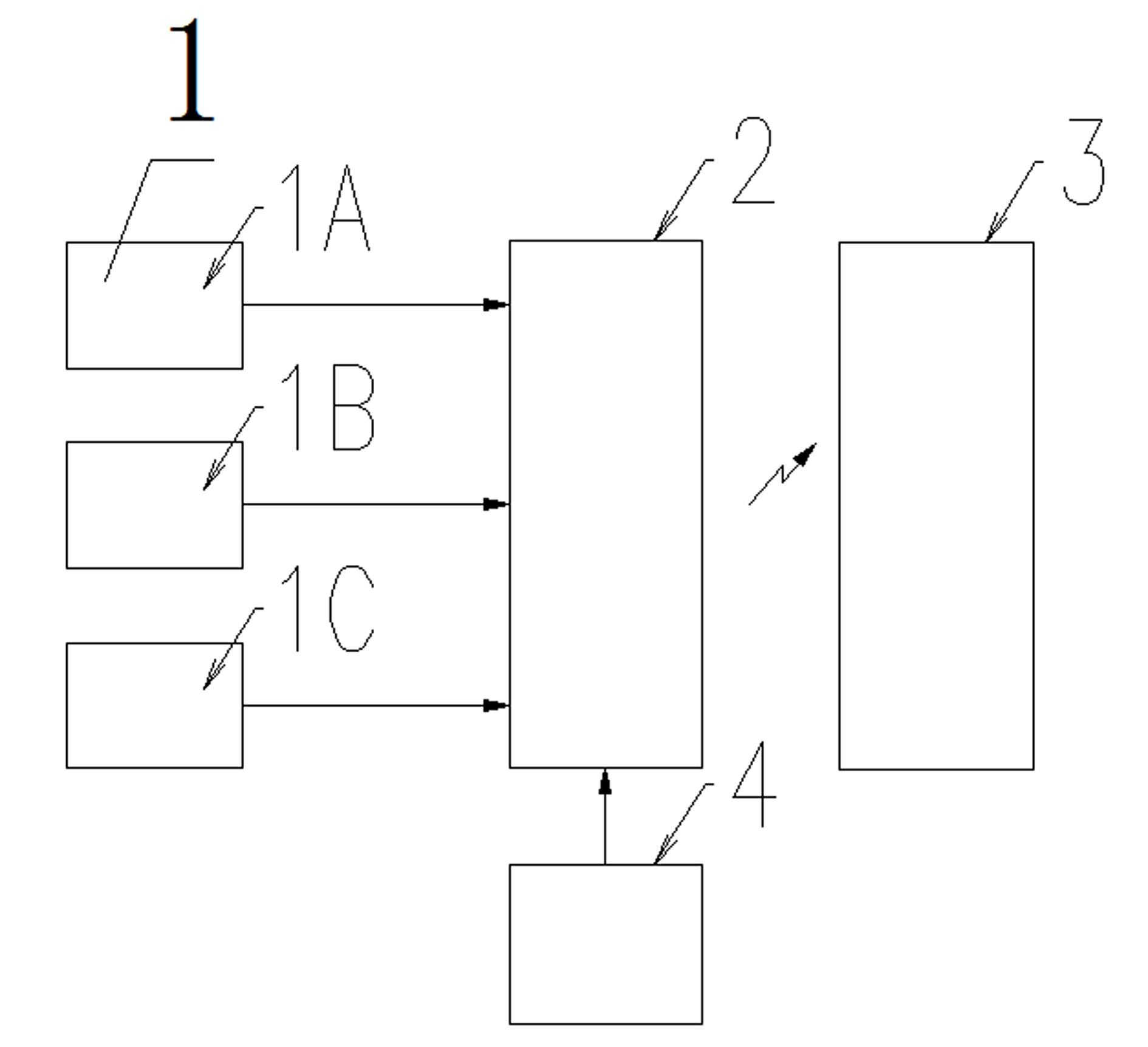

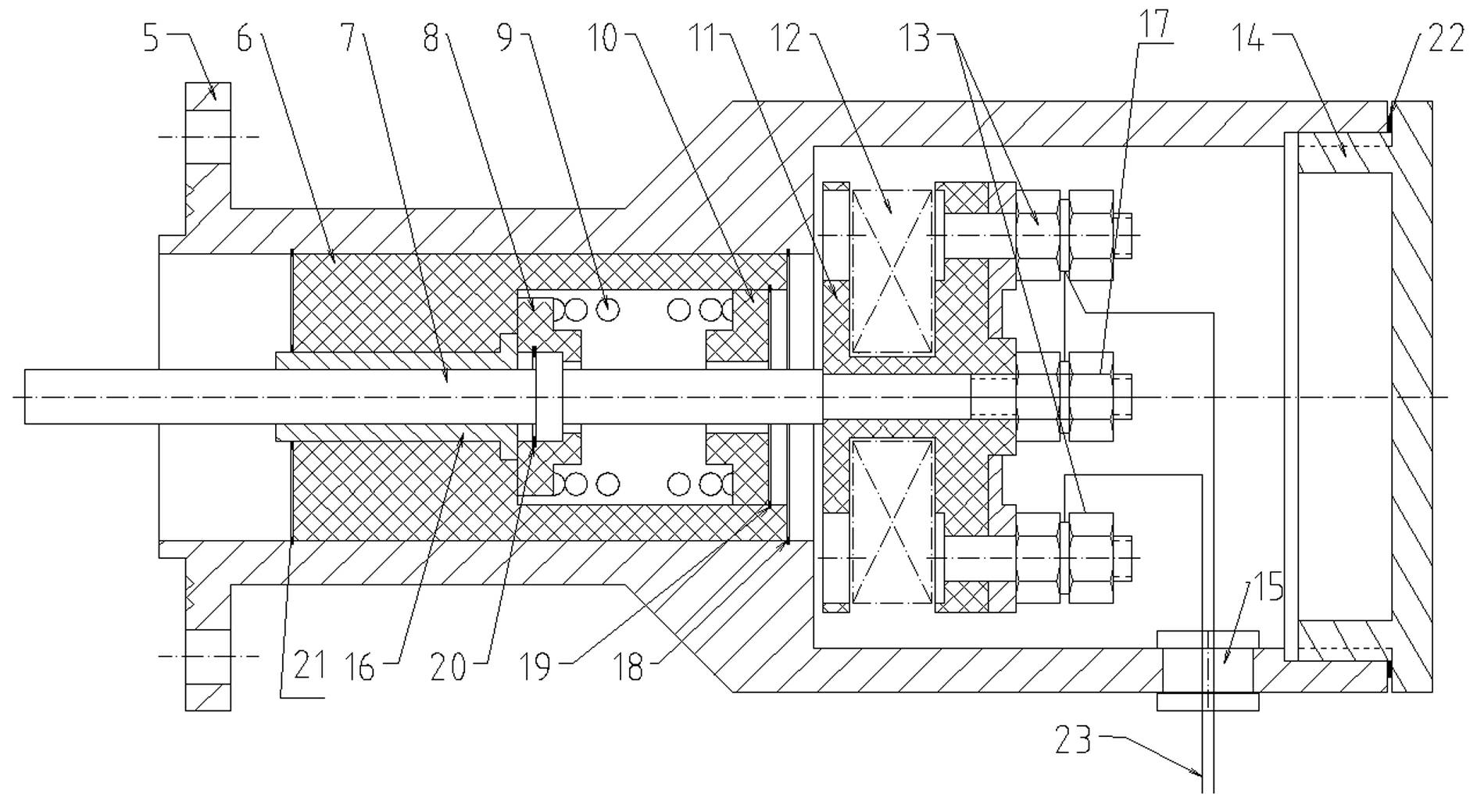

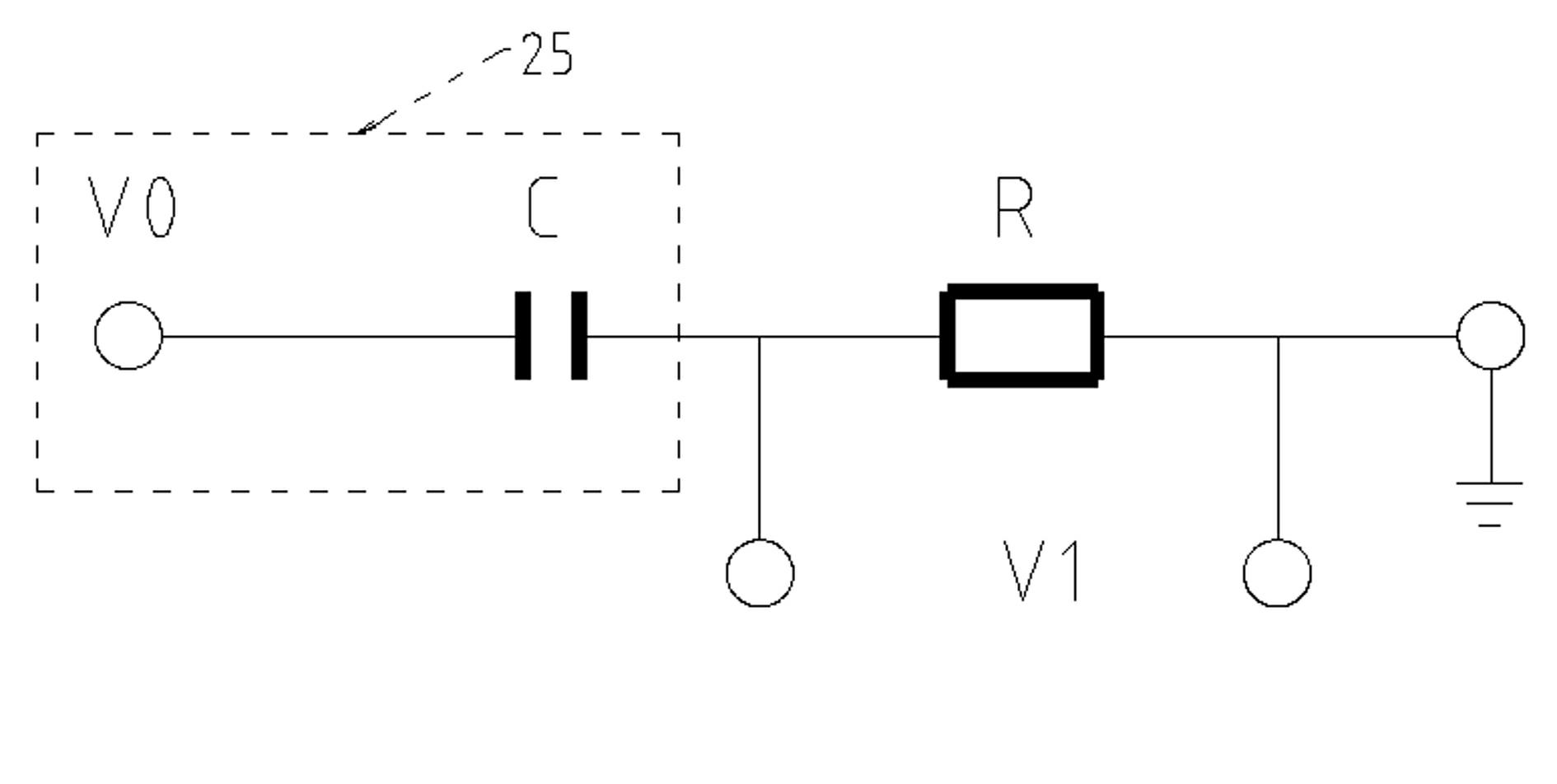

High-voltage transformer bushing tap grounding on-line monitoring device

A transformer bushing and monitoring device technology, applied in the field of power transmission and transformation, can solve the problems of inability to realize remote continuous monitoring, achieve reliable operation, reliable and stable working status, and overcome the effects of remote continuous monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0034] 1. Load 10KV high voltage to the high voltage side of the standard capacitor, check the grounding device of the last screen and the grounding detection circuit part, the sampling transmission device, the solar battery group, and the working conditions of the remote monitoring device, record the current value displayed by the remote monitoring device, and read continuously for 10 Take the average value as the actual measured current.

[0035] 2. Compare the measured current value with the theoretical current value under 10KV high voltage, and calculate the measurement deviation value.

[0036] Experimental example 2, load 110KV high voltage on the high voltage side of the standard capacitor for testing:

experiment example 2

[0037] 1. Load 110KV high voltage to the high voltage side of the standard capacitor, check the grounding device of the end screen and the grounding detection circuit part, the sampling transmission device, the solar battery group, and the working conditions of the remote monitoring device, record the current value displayed by the remote monitoring device, and read continuously for 10 Take the average value as the actual measured current.

[0038] 2. Compare the measured current value with the theoretical current value under 110KV high voltage, and calculate the measurement deviation value.

[0039] Experimental example 3, load 220KV high voltage on the high voltage side of the standard capacitor for testing:

experiment example 3

[0040] 1. Load 220KV high voltage to the high voltage side of the standard capacitor, check the grounding device of the end screen and the grounding detection circuit part, the sampling transmission device, the solar battery group, and the working conditions of the remote monitoring device, record the current value displayed by the remote monitoring device, and read continuously for 10 Take the average value as the actual measured current.

[0041] 2. Compare the measured current value with the theoretical current value under 220KV high voltage, and calculate the measurement deviation value.

[0042] The above experiments prove that: the withstand voltage level of the last screen grounding device 1 meets the insulation requirements under 220KV high voltage; the sampling transmission device 2 works reliably, and the digital-to-analog conversion accuracy meets the requirements of the transformer safety monitoring system; the software function of the remote monitoring device 3 mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com