Optical image capturing lens for bar code reader

A barcode reading and optical technology, applied in the field of optical imaging lenses of barcode readers, can solve the problems of unfavorable manufacturing cost, small field of view, and difficult to manufacture structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

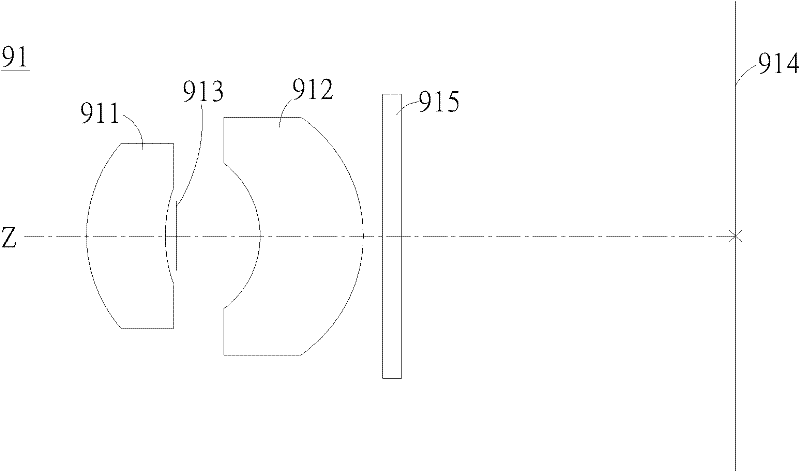

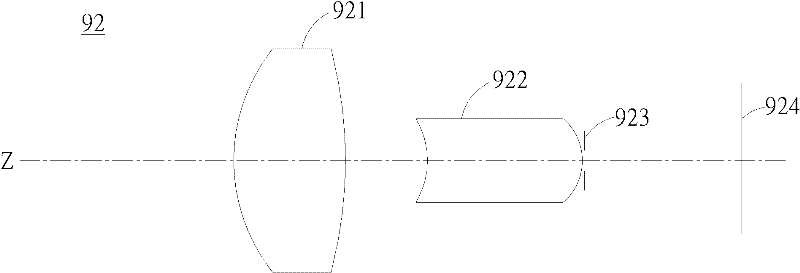

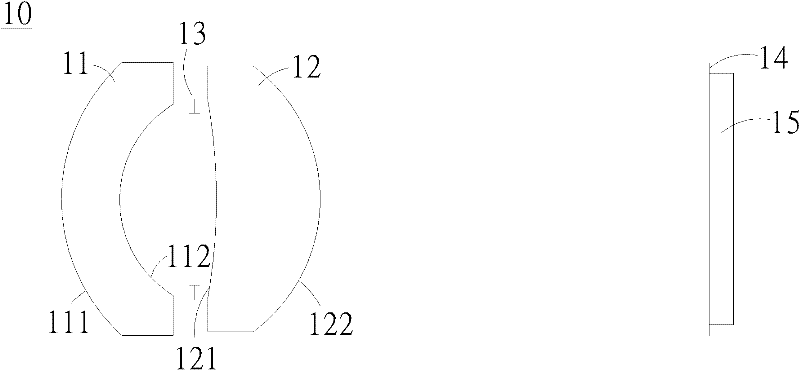

[0051] Please refer to the schematic diagram of the optical imaging lens of the barcode reader according to the first embodiment of the present invention. figure 2 , its light path schematic diagram please refer to image 3 , for the aberration curve of the first embodiment, please refer to Figure 4 . The optical imaging lens 10 of the barcode reader of the first embodiment is arranged along the optical axis from the object side to the image side and includes: a first lens 11 , an aperture stop 13 , a second lens 12 and an image sensor 15 . Wherein, the first lens 11 is a crescent lens, the first lens object-side optical surface 111 is a convex surface, the second lens image-side optical surface 112 is a concave surface, and the first lens object-side optical surface 111 is optically aligned with the first lens image-side optical surface. The surfaces 112 are all aspheric surfaces, satisfying the aspheric surface equation of formula (8); the second lens 12 is a crescent le...

no. 2 example

[0063] For the aberration curve of the second embodiment of the present invention, please refer to Figure 5 The optical imaging lens 10 of the barcode reading machine of the second embodiment is arranged along the optical axis from the object side to the image side and includes: a first lens 11, an aperture stop 13, a second lens 12 and an image sensing element 15 . Wherein, the first lens 11 is a crescent lens, the first lens object-side optical surface 111 is a convex surface, the second lens image-side optical surface 112 is a concave surface, and the first lens object-side optical surface 111 is optically aligned with the first lens image-side optical surface. The surfaces 112 are all aspherical surfaces, satisfying the aspherical surface equation of formula (8); the second lens 12 is a crescent lens, the second lens object side optical surface 121 is a concave surface, and the second lens image side optical surface 122 is a convex surface, and the second lens object side...

no. 3 example

[0075] For the aberration curve of the third embodiment of the present invention, please refer to Figure 6 The optical imaging lens 10 of the barcode reading machine of the third embodiment is arranged along the optical axis from the object side to the image side and includes: a first lens 11, an aperture stop 13, a second lens 12 and an image sensing element 15 . Wherein, the first lens 11 is a crescent lens, the first lens object-side optical surface 111 is a convex surface, the second lens image-side optical surface 112 is a concave surface, and the first lens object-side optical surface 111 is optically aligned with the first lens image-side optical surface. The surfaces 112 are all aspheric surfaces, satisfying the aspheric surface equation of formula (8); the second lens 12 is a crescent lens, the second lens object side optical surface 121 is a concave surface, and the second lens image side optical surface 122 is a convex surface, and the second lens object side optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com