Method for designing energy-saving type circulating cooling water system

A technology of circulating cooling water and design method, applied in computing, special data processing applications, instruments, etc., can solve the problems of high energy consumption of circulating water system, save operating costs and energy costs, good computing science, high thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

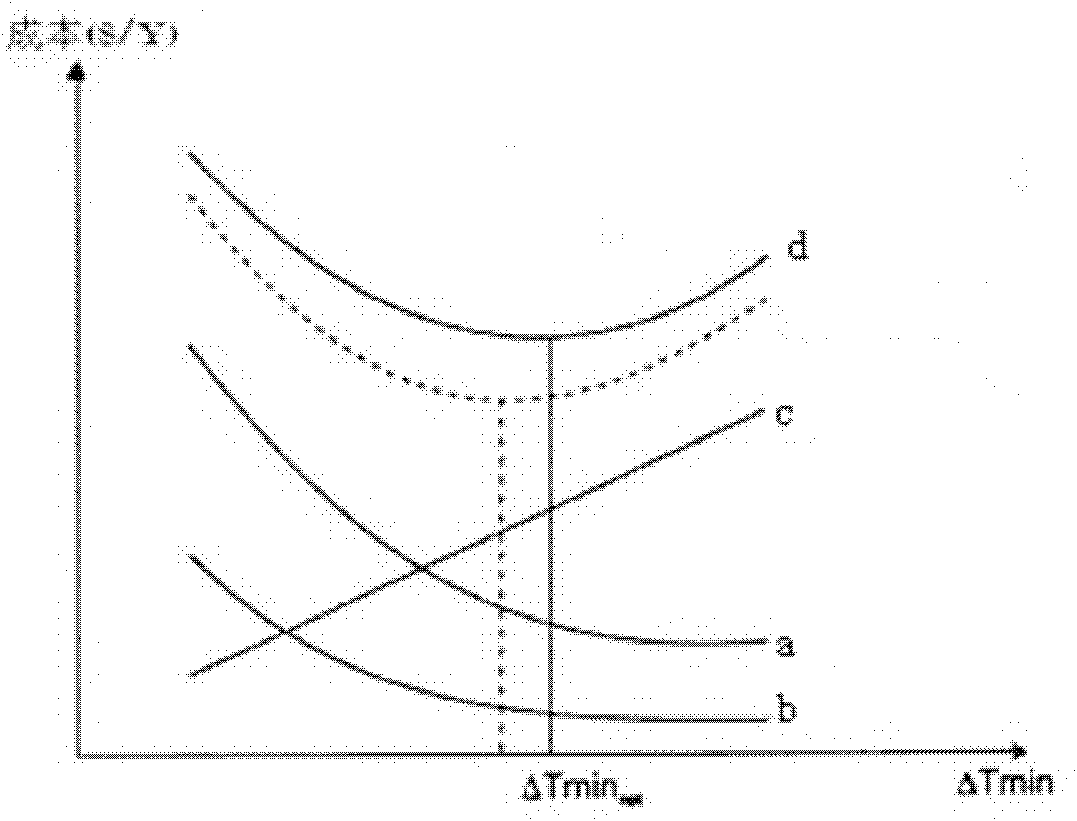

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Select a 300,000-ton synthetic ammonia plant circulating cooling water system for optimal design.

[0025] The engineering overview of the process circulation cooling water system in this embodiment is as follows: 7 cooling water pumps are equipped, 2 of which are equipped with a power of 2240kW, 1 with a power of 900kW, and 4 with a power of 1000kW, correspondingly equipped with 7 cooling towers. The operation mode is divided into two operation modes: general operation mode: 1 large (2240kW) cooling pump + 3 small (1000kW) cooling pumps + 7 cooling towers + cooling equipment (synthetic ammonia plant + power plant + soda ash plant); 9 Monthly (270 days*24 hours) operation; summer operation mode: 1 large (2240kW) cooling pump + 4 small (1000kW) cooling pumps + 7 cooling towers + cooling equipment (synthetic ammonia plant + power plant + soda ash plant); every year 7, 8, and 9 months (90 days * 24 hours) operation; first explore the production process and circu...

Embodiment 2

[0027] Example 2: Select a 1780 blast furnace blower turbine driving device circulating cooling water system in a steel plant.

[0028] The engineering overview of the circulating cooling water system in this embodiment is as follows: the cooling water system is mainly used for the cooling of the condensers and auxiliary machines of the three blower turbine driving devices of the 1780 blast furnace, and the condensers equipped with each blower turbine driving device are replaced. The thermal area is 1900m 2 , double-channel condensation; the pump station is equipped with 6 sets of 900kW cooling pumps (2 for use and 4 for standby); the operation mode before technical transformation: 2 sets (900kw) of cooling pumps + 2 sets of blower turbine driving devices; this embodiment involves 6 sets in total The water pump is equipped with an independent metering system, which can independently accumulate running time and power consumption. The operating mode is as follows:

[0029] Ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com