Method for on-line monitoring of quality of ONO (Oxide-Nitride-Oxide) film in SONOS (Silicon Oxide Nitride Oxide Semiconductor) memory process

A memory and process technology, applied in the field of monitoring ONO film quality, can solve the problems of production line risks, inability to judge the quality of ONO film in real time, etc., and achieve the effect of avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

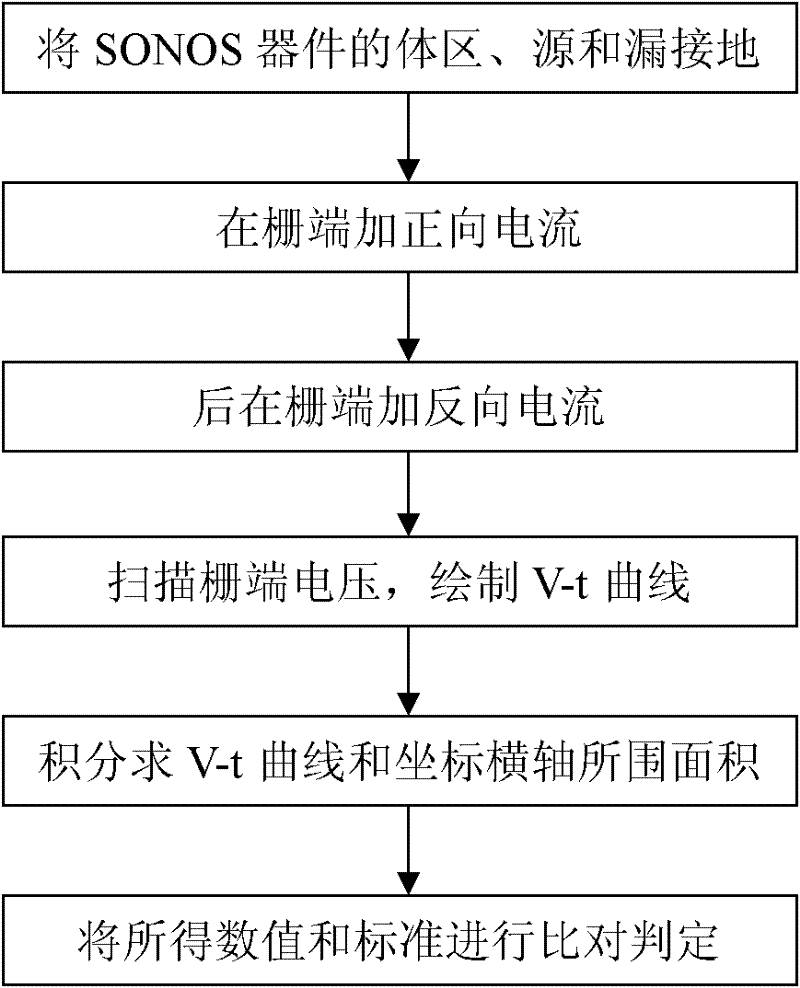

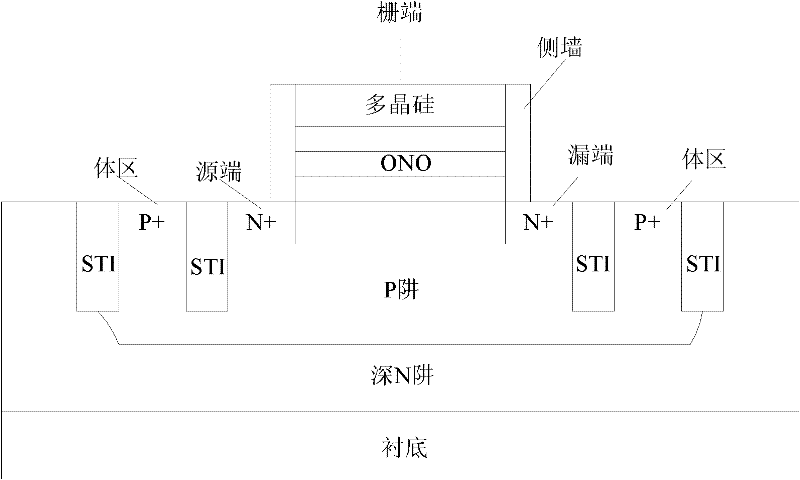

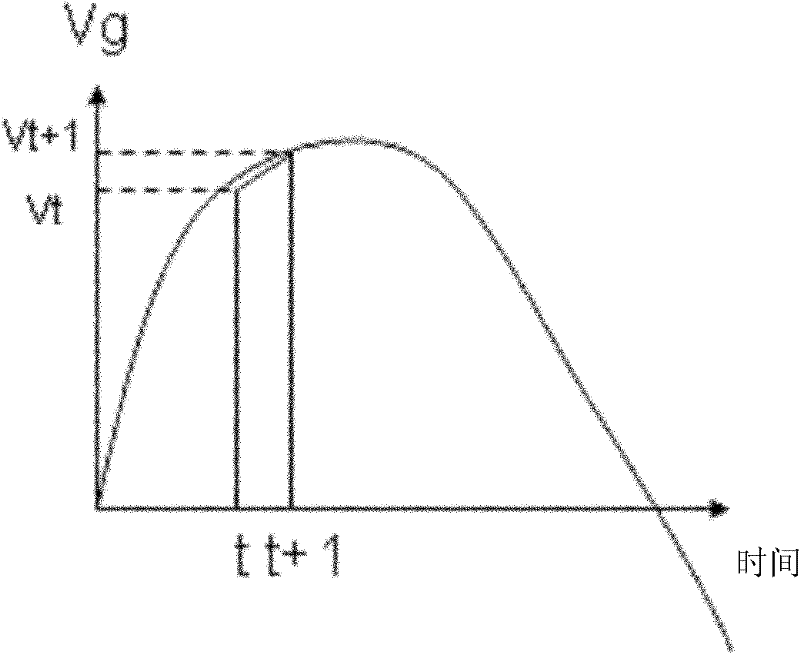

[0019] The method for on-line monitoring of the quality of the ONO film of the present invention is a creative proposal to use the method of charge capture and release to detect the quality of the ONO film on-line. The method simulates writing and erasing of the SONOS structure memory by means of forward injection and reverse extraction of stable current. During the current reverse extraction process, the reverse voltage is sampled and scanned, and the area enclosed by the scanned V-t (voltage-time) curve and the coordinate horizontal axis is calculated by integration. The physical meaning of the obtained area is the ability of the defects in the film to capture electrons. Therefore, the area value obtained by the integral is used to evaluate the quality of the ONO film.

[0020] Method of the present invention, after forming SONOS core device (that is to have formed the gate of SONOS memory, source region, drain region and body region) structure is test structure, specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com