Real-time control intelligent alternating-current contactor with full-closed loops

An AC contactor, real-time control technology, applied in relays, electrical components, circuits, etc., can solve the problems of difficulty in intelligent control of AC switch electrical appliances, and achieve the effect of reducing large inrush current and strengthening the protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

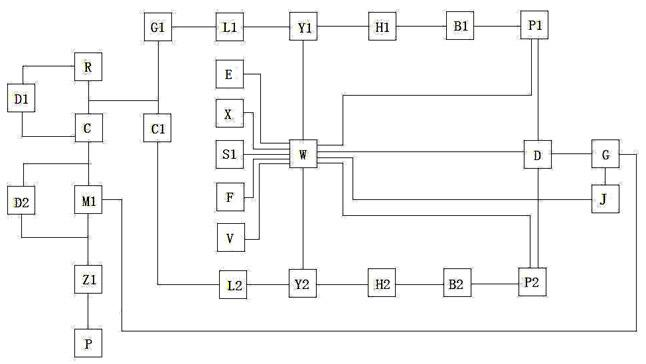

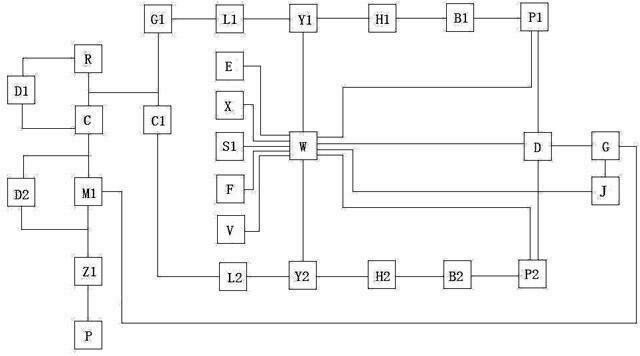

[0025] The invention provides a fully closed-loop real-time control intelligent AC contactor, including a rectified power supply, characterized in that: the power supply supplies power to the contactor coil through a power electronic switch, and the contactor coil is provided with sampling resistance and current Sampling sensor, the sampling resistance sequentially passes through an isolation circuit, a first filter circuit, a first program-controlled operational amplifier, a first PID or hysteresis control circuit, a first compensation network, a first PWM control circuit, a multiplexer, The isolated drive circuit is connected with the power electronic switch to form a closed-loop start-up, which can accurately control the start-up current of the AC contactor; the current sampling sensor passes through the second filter circuit, the second program-controlled operational amplifier, the second PID or the The loop control circuit, the second compensation network, the second PWM c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com