Lateral pump module of semiconductor module

A laser and semiconductor technology, applied in the laser field, can solve the problem of poor pumping uniformity, achieve the effect of solving the problem of pumping uniformity, reducing thermal effects, and improving beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

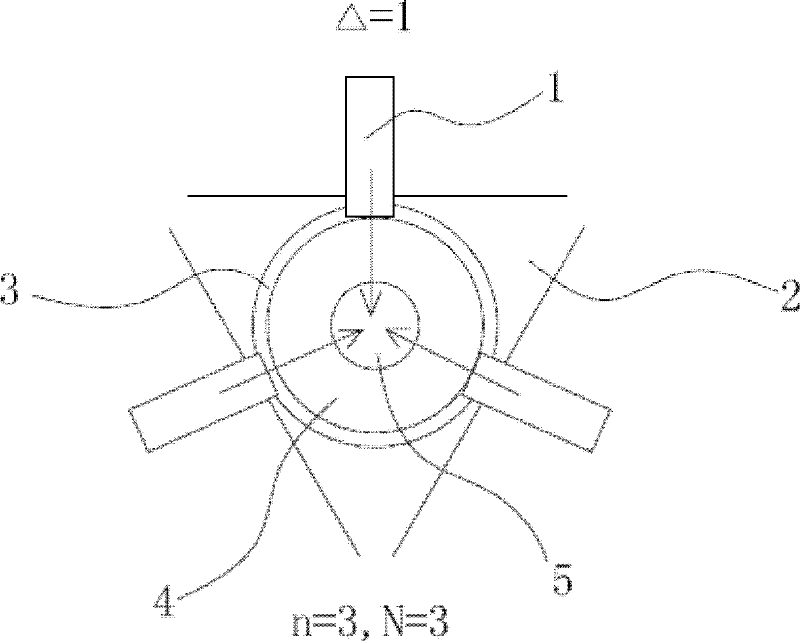

[0040] figure 1 After the middle pump source 1 uses three-directional pump crystal rods, the distribution of pump fluorescence presents a triangular shape, thereby realizing the use of the three-directional surround pump source 1 to improve pumping uniformity.

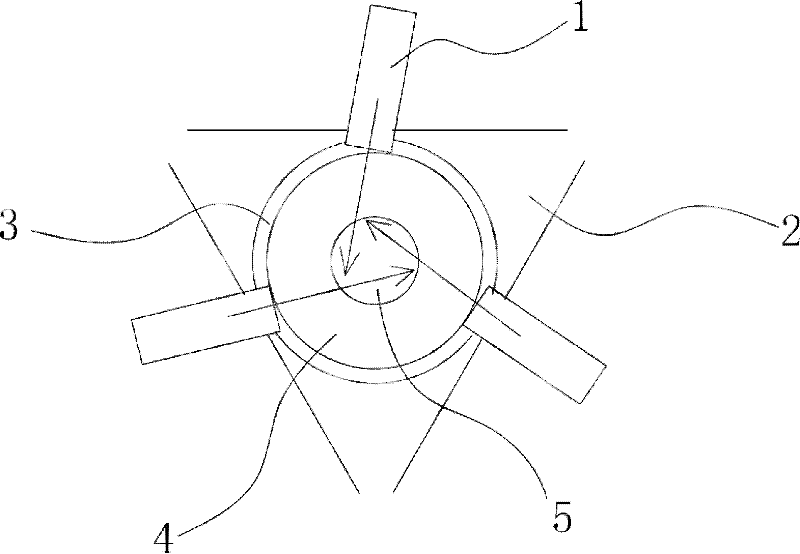

[0041] as figure 1 A further modification of the structure shown in, figure 2 In the middle, the pump source 1 is deviated from the optical axis of the crystal rod 5 at a certain angle to form an off-axis pump, and the pump uniformity is further improved due to the presence of a certain dislocation overlapping area of the pump light.

[0042] Among them, n is the number of pumping directions, N is the number of equivalent pumping directions, Δ is the number of rotations around the crystal rod, θ is the rotation angle along the optical axis of the crystal rod, and n is optional in the range of 1 to 10.

Embodiment ( 2

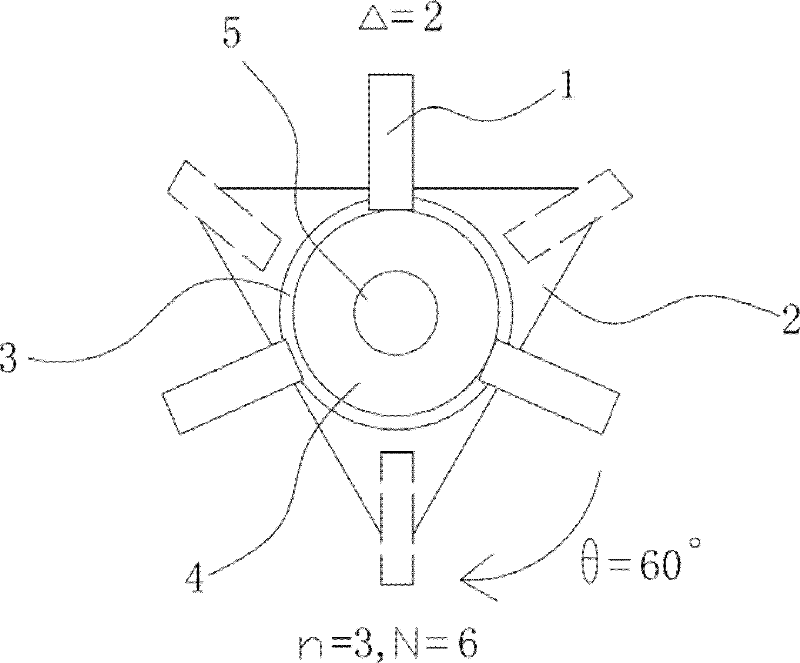

[0044] Due to the limitation of the size of semiconductor lasers, it is impossible to realize multi-directional compact pumping structures such as four-directional, five-directional, six-directional, seven-directional, and nine-directional. Therefore, the present embodiment (2) is a modification of the embodiment (1), which rotates the pump source 1 in the embodiment (1) at an angle of 60° along the optical axis of the crystal rod 5, so that the rotated The pumping structure is equivalent to a six-way pumping structure.

[0045] That is, will figure 1 After the pump source 1 of the three-way pump is rotated along the optical axis of the crystal rod by an angle of θ=60°, it is equivalent to a six-way pump structure.

[0046] as image 3 A further modification of the structure shown in, Figure 4 In the middle, the pump source 1 is deviated from the optical axis of the crystal rod 5 at a certain angle to form an off-axis pump. Since the pump light has a certain dislocation ov...

Embodiment ( 3

[0049] This embodiment is the same as embodiment (two), and is also a modification of embodiment (one).

[0050] Figure 5 In the above, the pump source 1 surrounds the crystal rod 5 at equal intervals, and the figure 1 The pumping source of the three-way pumping structure rotates twice along the optical axis of the crystal rod 5, and rotates 40° each time. The pumping structure after rotation is equivalent to the nine-way pumping structure, which greatly improves the uniformity of the pumping. sex.

[0051] as Figure 5 A further variant of the structure shown in the figure, Figure 6 The pumping source 1 is deviated from the optical axis of the crystal rod 5 at a certain angle to form off-axis pumping, and the pumping uniformity can be further improved because the pumping light has a certain dislocation overlapping area.

[0052] Similarly, in the present embodiment (3), an off-axis pump coupling structure can also be used, that is, the pump source 1 and the center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com