Device for boundary layer gettering and composite component therefor

A composite component and boundary layer technology, applied in boundary layer control, aircraft parts, transportation and packaging, etc., can solve problems such as influence, long manufacturing time, and stringer-consuming manufacturing technology, and achieve high quality and reduce manufacturing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

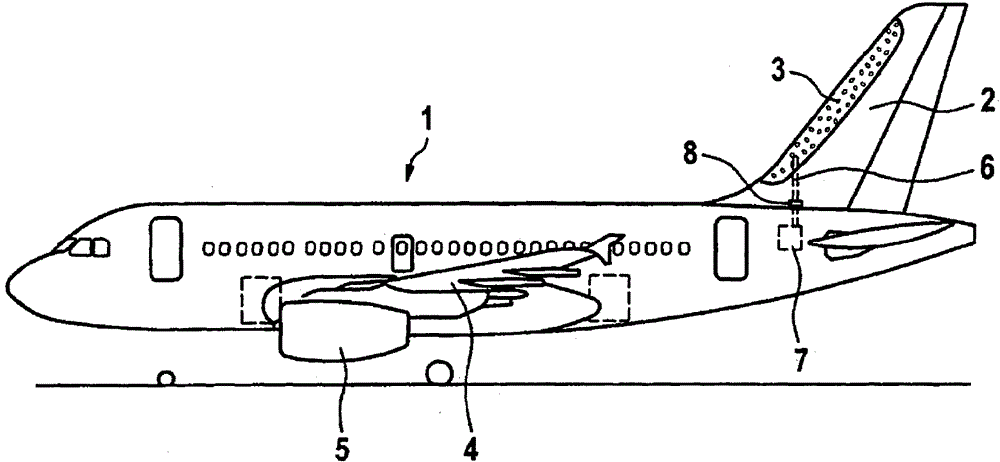

[0027] according to figure 1 , in the region of the vertical tail 2 there is an absorbable surface 3 on the outer skin 1 of the civil aircraft shown here by way of example. In addition, similar absorbable surfaces, not shown in further detail, are provided on the other aerodynamic components, here on the wing 4 and on the nacelle 5 , for the boundary Components of the device for layer gettering.

[0028] The suction surface 3 of the vertical stabilizer 2 is connected via a suction line 6 shown here only schematically to a suction source 7 which generates the necessary negative pressure to suck off the air on the surface 3. boundary layer. To adjust the air mass flow, a perforated plate 8 is inserted into the suction line 6 of the device for boundary layer suction.

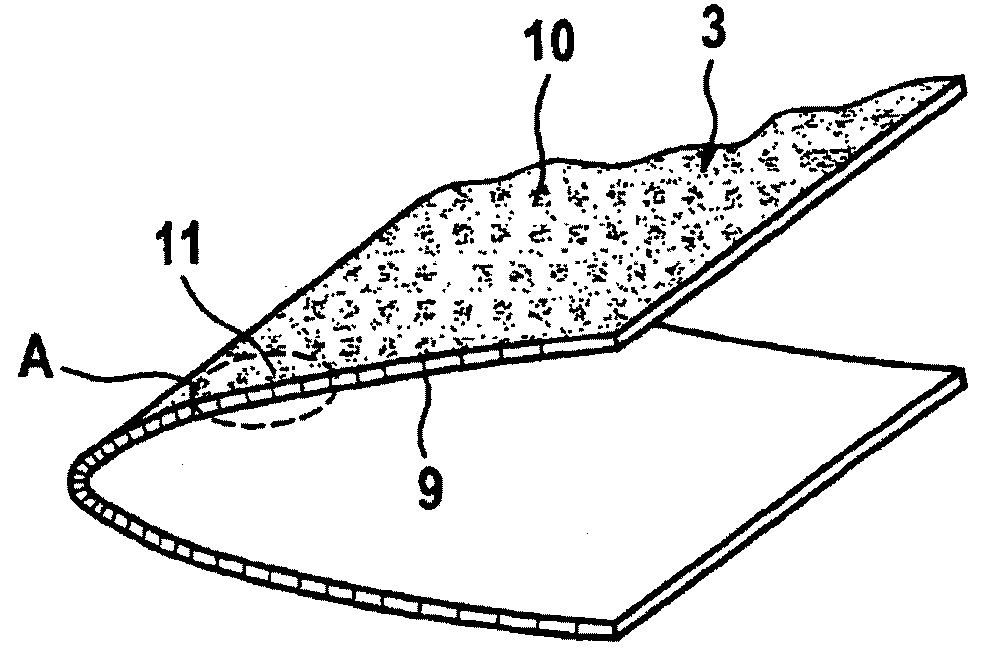

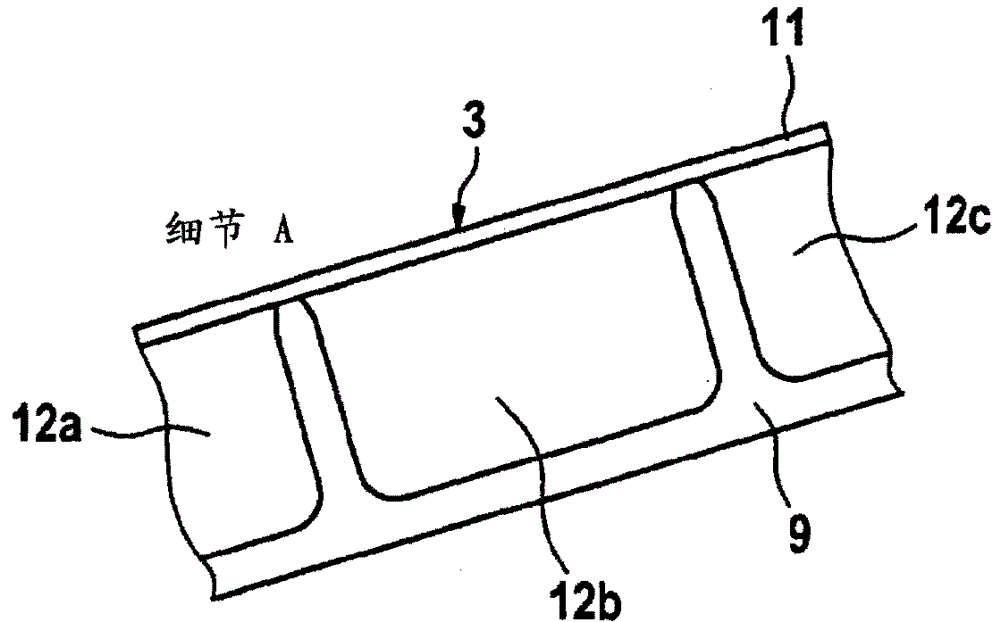

[0029] The position of the absorbable surface 3 of the vertical stabilizer 2 not shown in further detail figure 2 The section shown in has a surface penetrated by the smallest through-hole 10 of about 40 μm to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com