Hollow rotor misalignment channel hydraulic rotary piston multi-pass supercharger

A hollow rotor and rotary piston technology, applied in fluid pressure converters, permeation/dialysis water/sewage treatment, seawater treatment, etc., can solve additional costs such as increased equipment investment and daily management and maintenance, and the highest exchange efficiency does not exceed 95 %, frequent accidents and other problems, to avoid electrical accidents, eliminate the effect of self-weight, and improve the force-bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

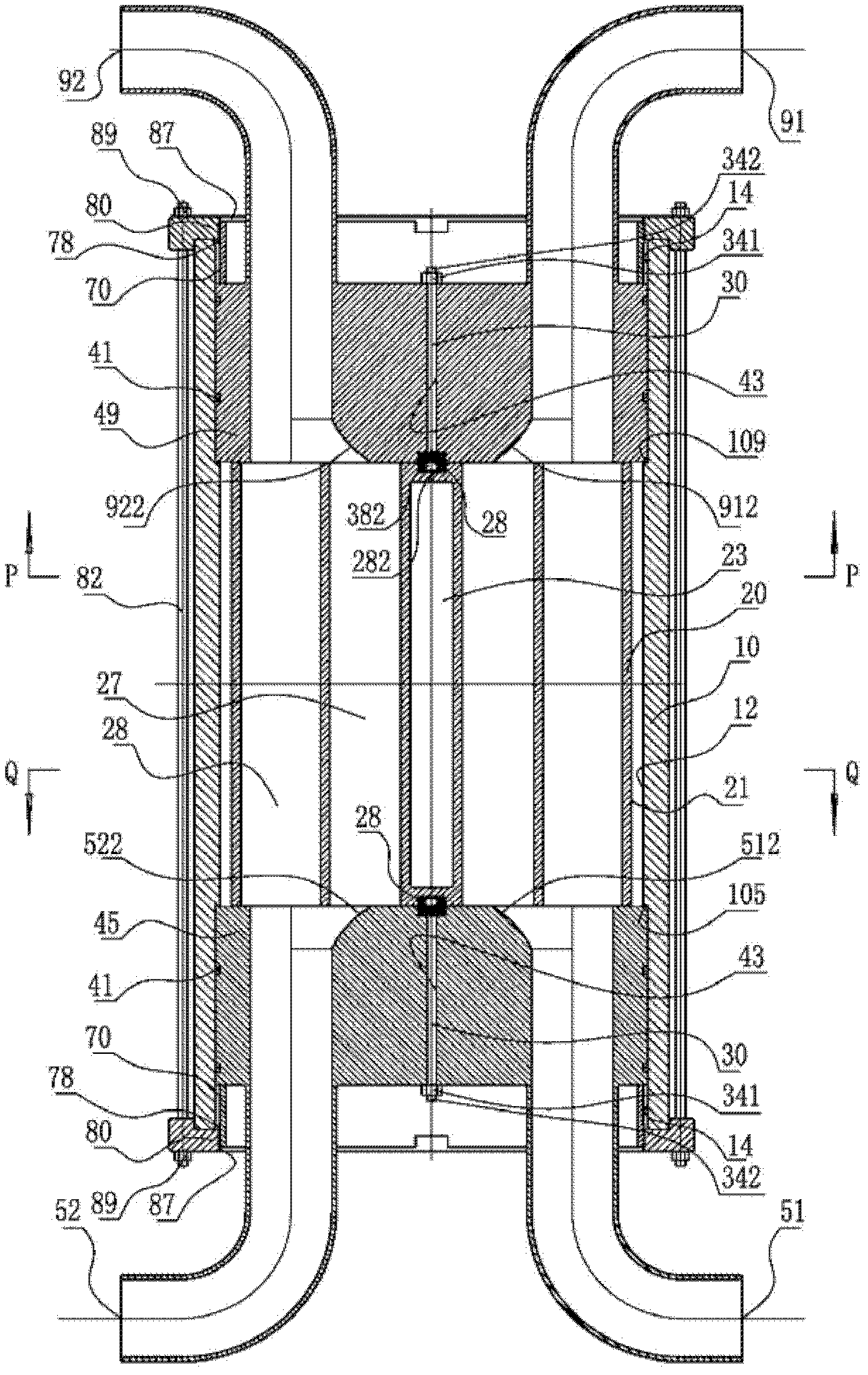

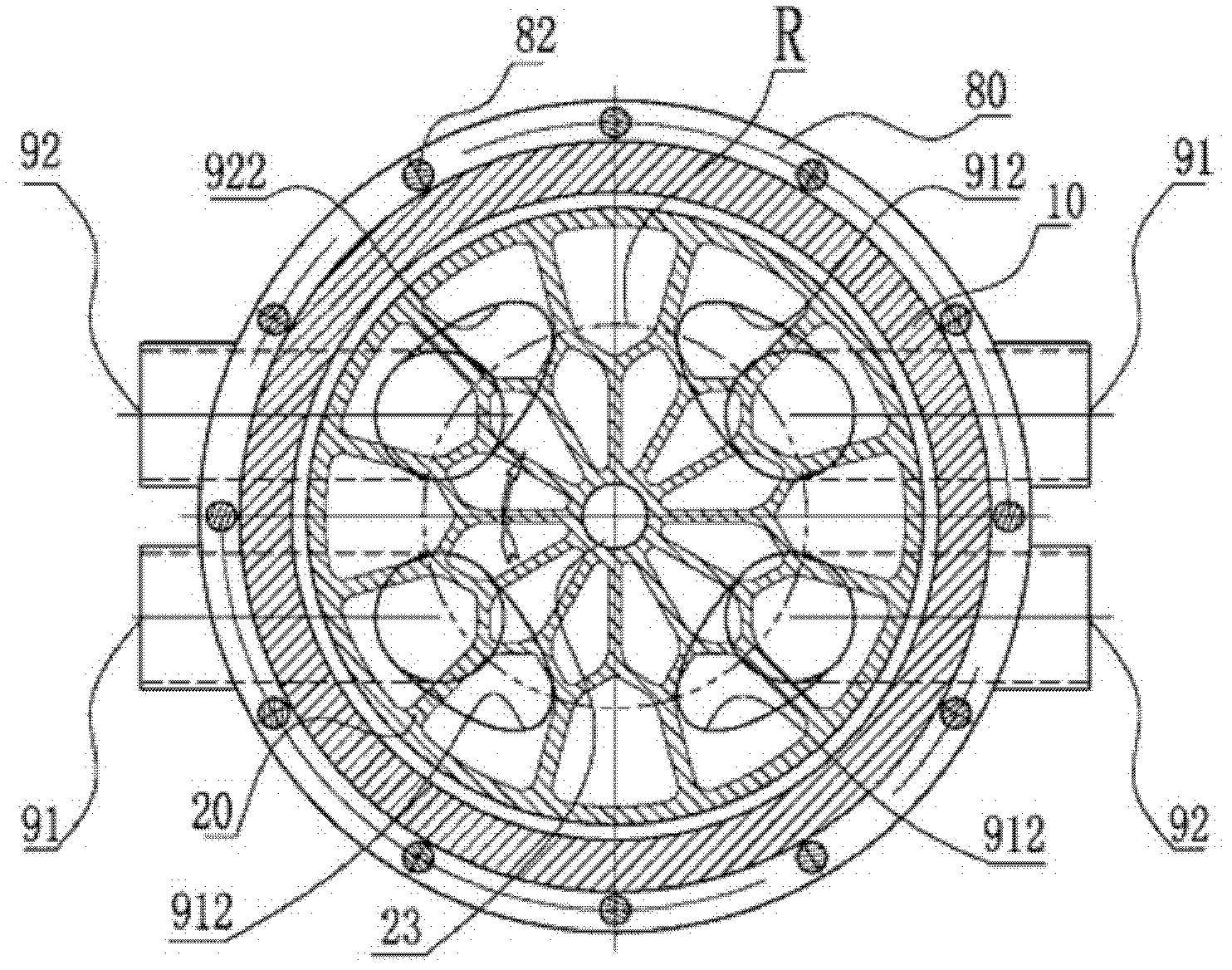

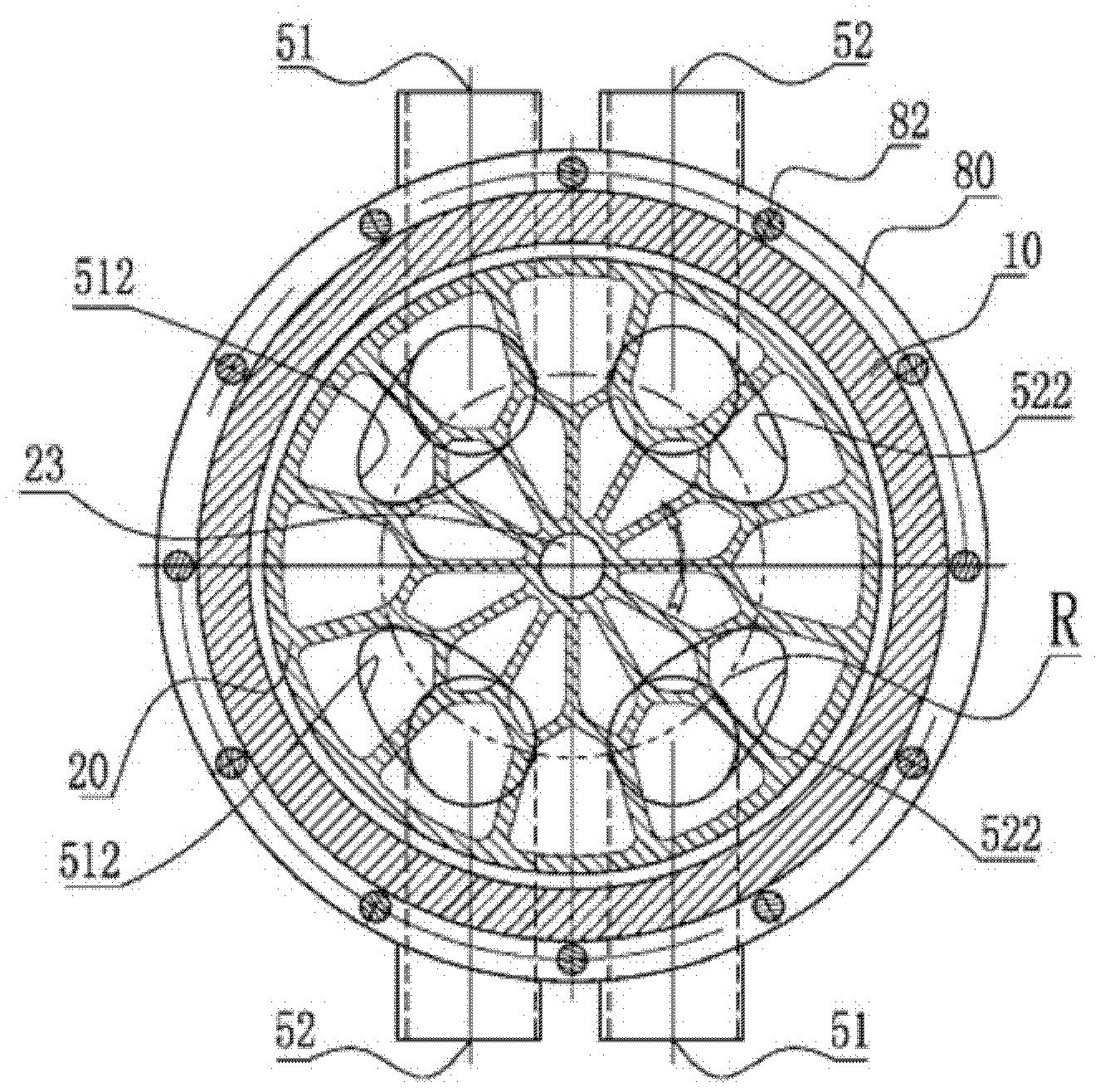

[0041] The structure and working principle of the present invention and the application in the reverse osmosis seawater desalination system are further elaborated in conjunction with the accompanying drawings and embodiments:

[0042] figure 1 It is a structural schematic diagram of a self-rotating hydraulic piston supercharger with dislocation channels, reflecting the overall assembly relationship of the present invention. Cooperate figure 2 , image 3 , Figure 4 as well as Figure 5 is true figure 1 The cross-sectional views of different parts reflect the mutual positional relationship between the inlet and outlet channels of the present invention.

[0043] A hollow rotor dislocation channel hydraulic rotary piston multi-pass supercharger, the two ends of the cylindrical shell 10 are end cover flanges 80, the outer edge of the end cover flange 80 is provided with flange bolts 82; the end cover flange 80 The inner hole thread 87 is connected with the screw cap externa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com