Large energy-saving water cooling air hammer

A water cooling and air hammer technology, applied in power hammers, hammer drive devices, forging/pressing/hammer devices, etc. The effect of reducing power consumption, small current fluctuation and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

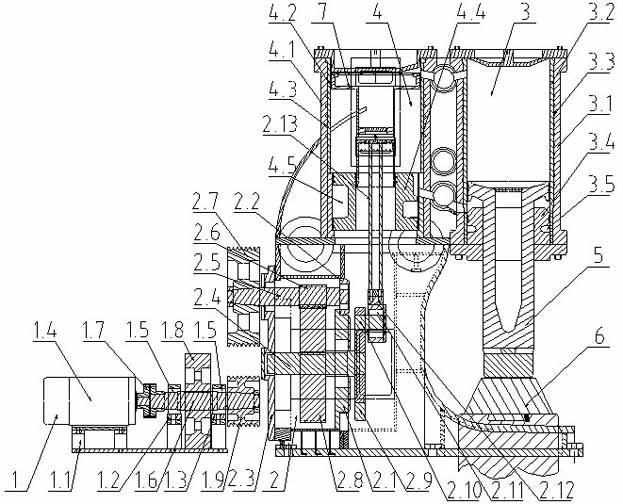

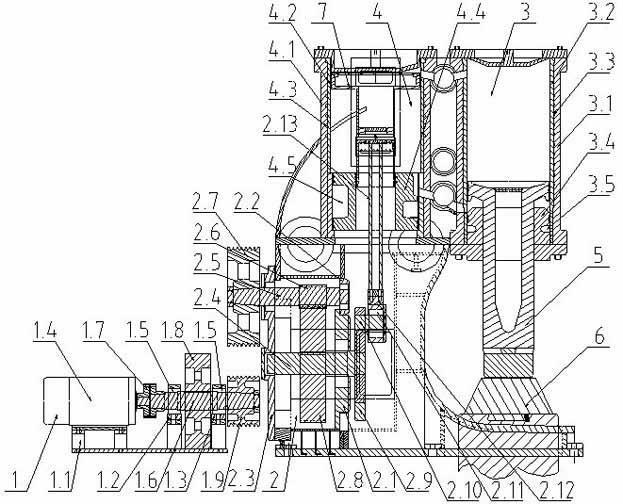

[0055] see figure 1 , the present invention relates to a large-scale energy-saving water-cooled air hammer, which includes a power transmission mechanism 1, a curved linkage mechanism 2, a front cylinder 3 and a rear cylinder 4, the front cylinder 3 and the rear cylinder 4 are arranged in parallel front and rear, and the front cylinder 3 is a working cylinder, and the rear cylinder 4 is a compression cylinder. The front cylinder 3 includes a front cylinder liner 3.1, a guide sleeve I3.2 is arranged inside the front cylinder liner 3.1, and a hammer rod is arranged inside the guide sleeve I3.2. 5 and the front lead 3.4, the front lead 3.4 is located at the lower end of the guide sleeve I3.2, the inner wall of the front cylinder liner 3.1 is provided with a water hole I3.3, and the outer wall of the front sleeve 3.4 is provided with a water hole II3.5 , the rear cylinder 4 includes a rear cylinder liner 4.1, the rear cylinder liner 4.1 is provided with a guide sleeve II4.2, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com