Anti-deformation special-shaped grinding wheel

A special-shaped, anti-lost technology, applied in the field of grinding tools, can solve the problems of reduced processing quality and efficiency, limited carry-out, large powder threads, etc., improve the performance of surface roughness and grinding wheel sharpness, and promote anti-corrosion Deformation ability, obvious effect of economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

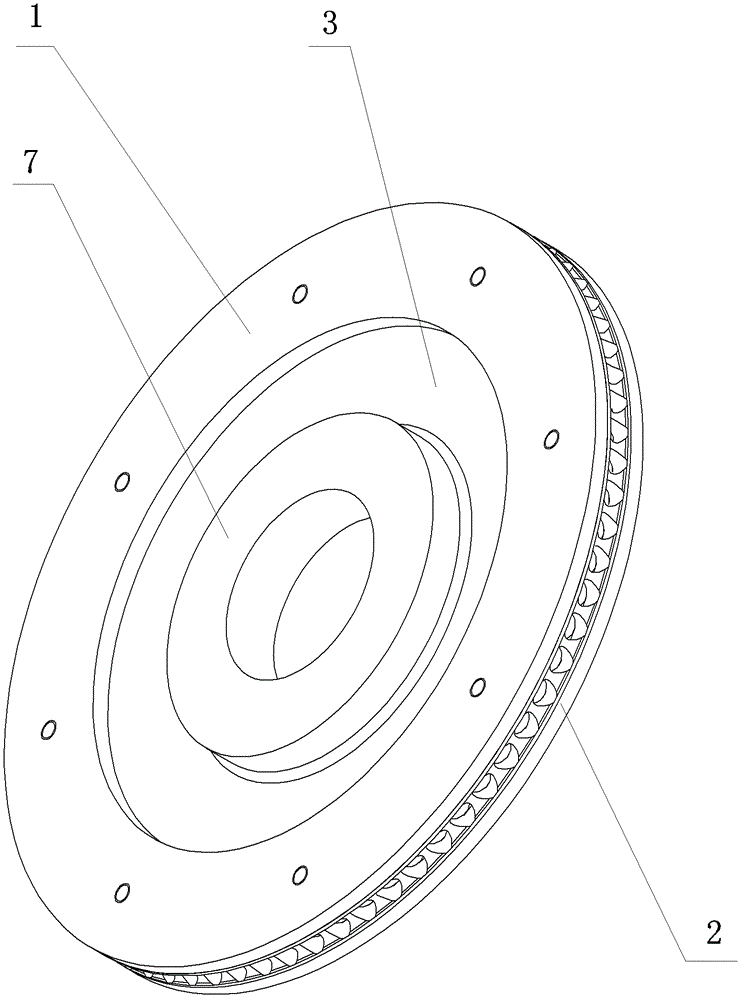

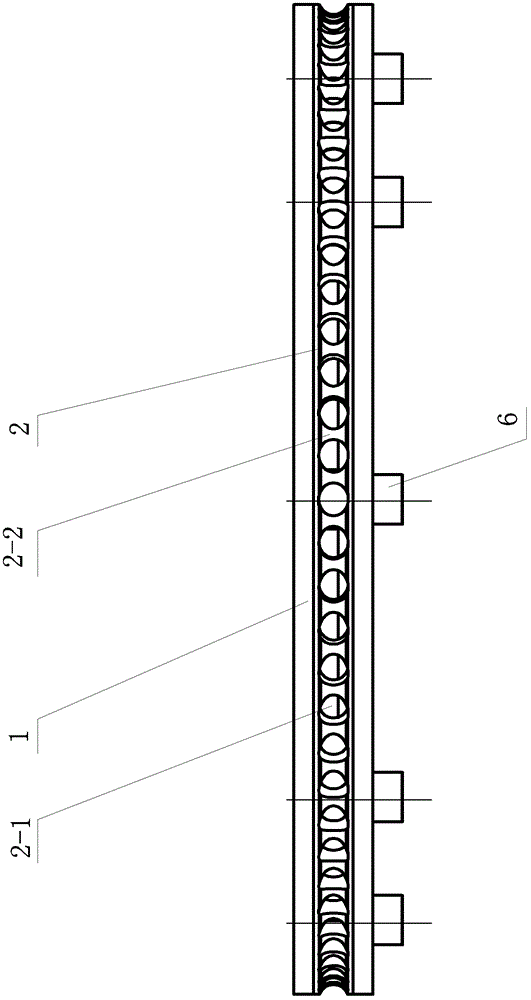

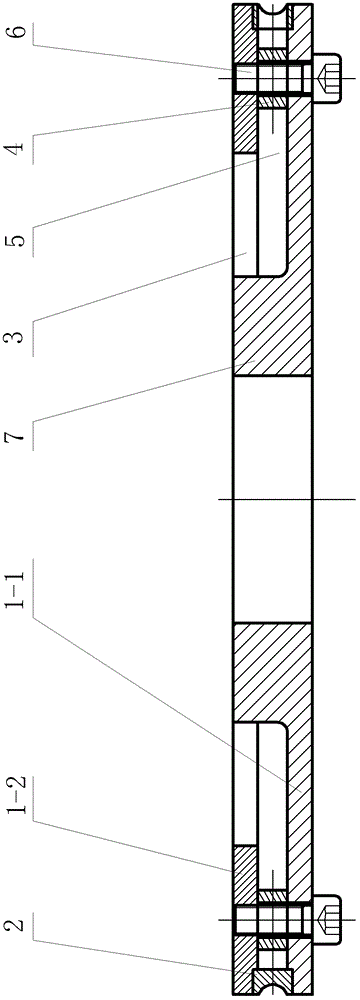

[0039] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

[0040] The anti-deformation special-shaped grinding wheel of the present invention is composed of a base body 1 and a grinding ring 2, wherein the base body 1 is assembled from a base plate 1-1 and a pressing plate 1-2.

[0041] The base plate 1-1 is a circular plate, the axis of the base plate 1-1 is a central axis 7, the axis hole of the central axis 7 is installed in cooperation with the grinding wheel shaft of the grinding machine, and the pressure plate 1-2 is a ring plate, The diameter of the outer ring of the pressing plate 1-2 is the same as the circumference diameter of the base plate 1-1, and the diameter of the inner ring of the pressing plate 1-2 is greater than the outer diameter of the central axis 7 of the base plate 1-1; between the base plate 1-1 and the pressing plate 1-2 The hollow supporting columns 4 evenly distributed on the circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com