Internal cooling type grinding wheel for external cooling type grinding machine

A cold grinding machine technology, applied in the field of grinding tools, can solve the problems of the irregular grinding surface of the grinding wheel, such as easy to lose shape, uneven processing volume, and different wear degrees, so as to improve the performance of surface roughness and sharpness of the grinding wheel, The effect of obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

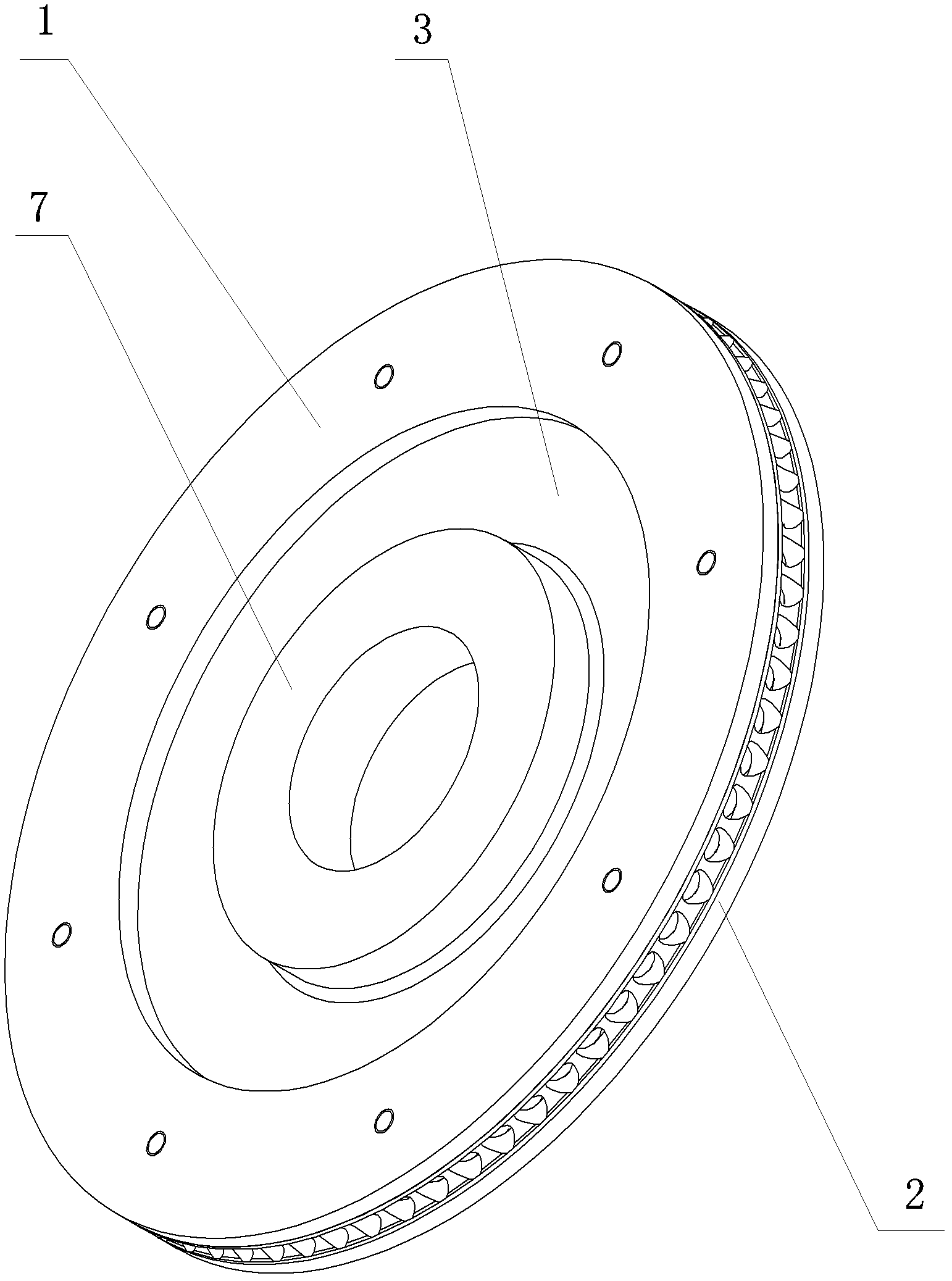

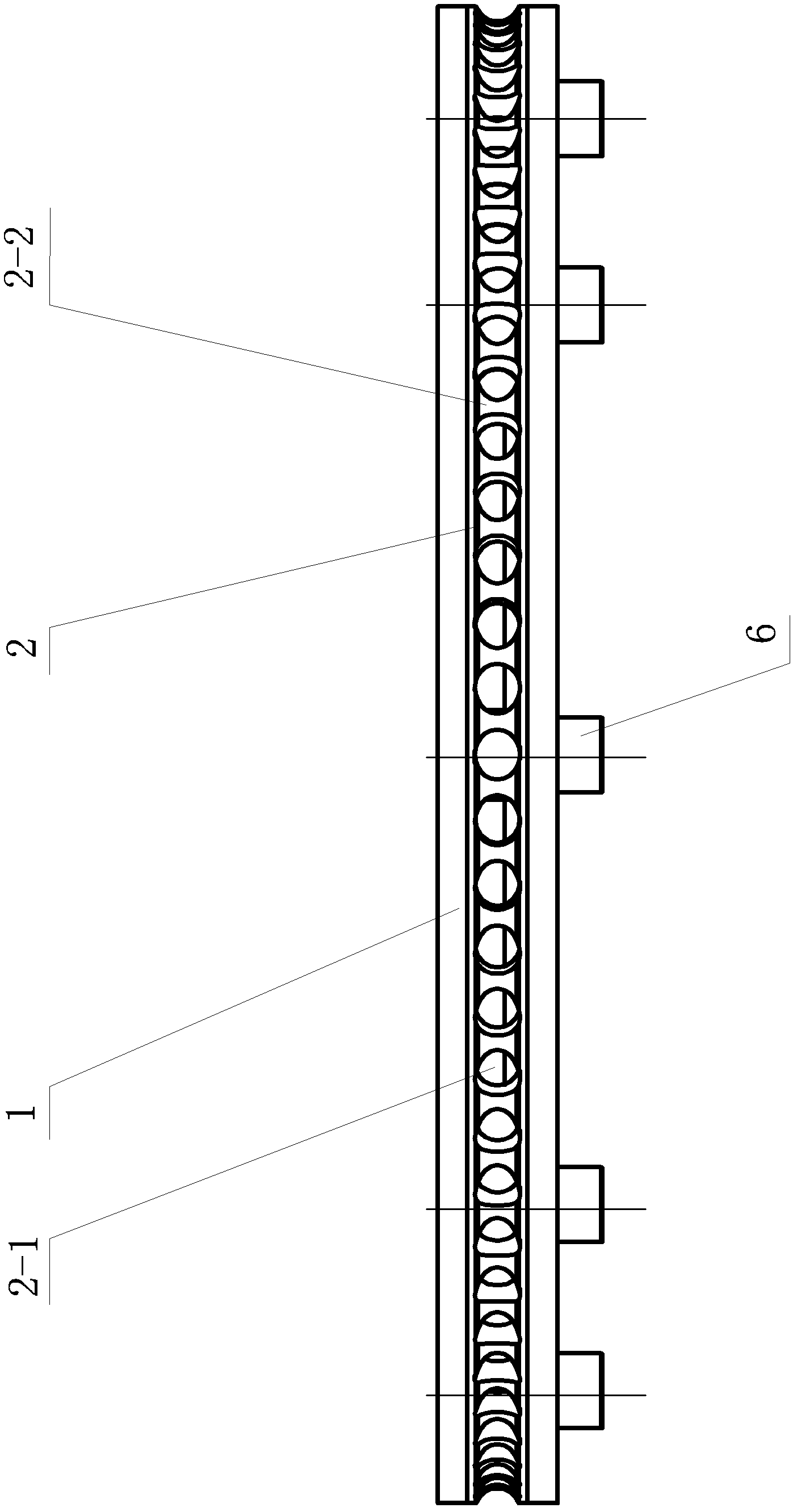

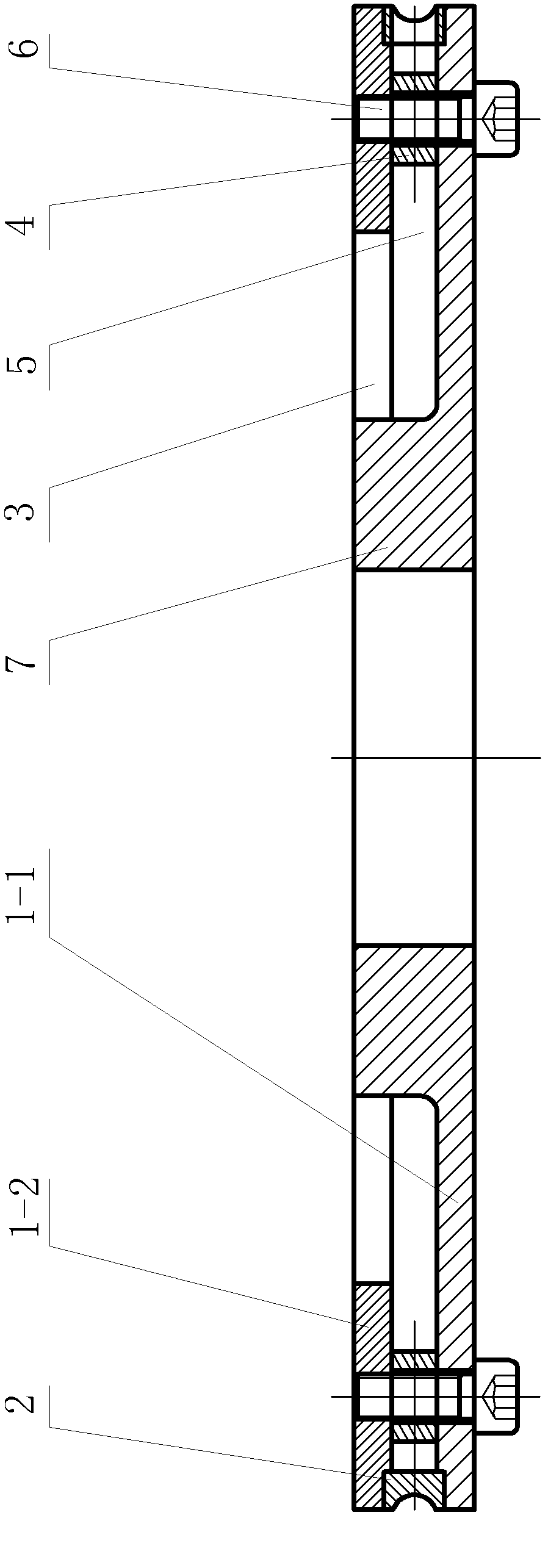

[0036] The internally cooled grinding wheel for an externally cooled grinding machine of the present invention is composed of a base body 1 and a grinding ring 2, wherein the base body 1 is assembled from a base plate 1-1 and a pressing plate 1-2.

[0037]The base plate 1-1 is a circular plate, the axis of the base plate 1-1 is the central axis position 7, the press plate 1-2 is a ring plate, and the diameter of the outer ring of the press plate 1-2 is the same as the circumference diameter of the base plate 1-1, The diameter of the inner ring of the pressure plate 1-2 is greater than the outer diameter of the central axis 7 of the base plate 1-1; the space between the base plate 1-1 and the pressure plate 1-2 is separated by hollow support columns 4 uniformly distributed on the circumference, corresponding to each support column 4 position, fasten the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com