Movable continuous stirring and spraying system for mine

A mobile and continuous technology, applied in the direction of unloading device, etc., can solve the problems of high dust concentration in underground space, endangering the health of workers, and high labor intensity of workers, so as to reduce the rebound rate of shotcrete, reduce labor intensity, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

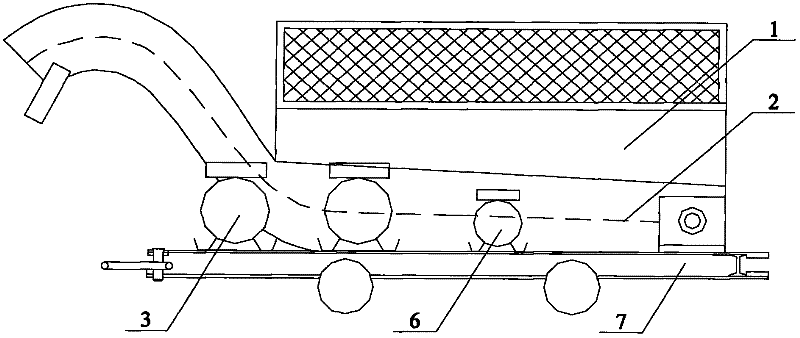

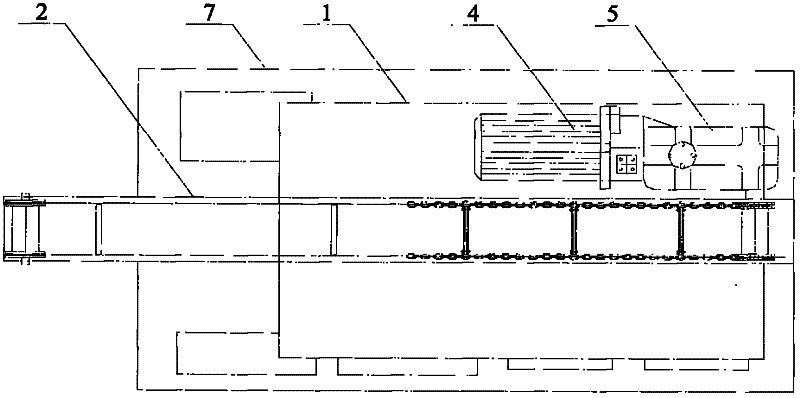

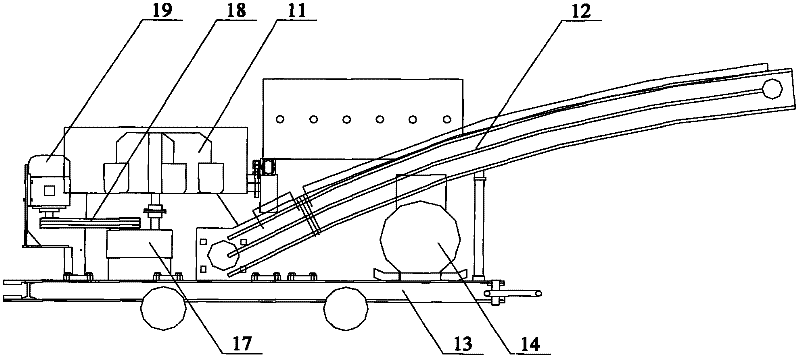

[0014] Such as Figure 1 to Figure 7 As shown, a mine mobile continuous mixing and spraying system involved in this embodiment includes: a shuttle car system, a stirring system and a spraying system, and the shuttle car system includes a storage bin 1, a scraper machine 2 , magnetic starter 3, shuttle car motor 4, shuttle car reducer 5, integrated lighting protection 6 and the first flat mine car 7, the storage bin 1 is fixed on the first flat mine car 7, and the scraper machine 2 is fixed In the lower part of the storage bin 1, the head of the scraper machine 2 is fixedly connected with the first flat mine car 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com