Automatic assembling line for water pen

An assembly line and automatic installation technology, which is applied in the repair of ink pens, ink filling devices, transportation and packaging, etc., can solve the problems of affecting assembly efficiency, high labor intensity, waste of manpower, etc., to improve operation accuracy and service life, The effect of reducing labor intensity and saving assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

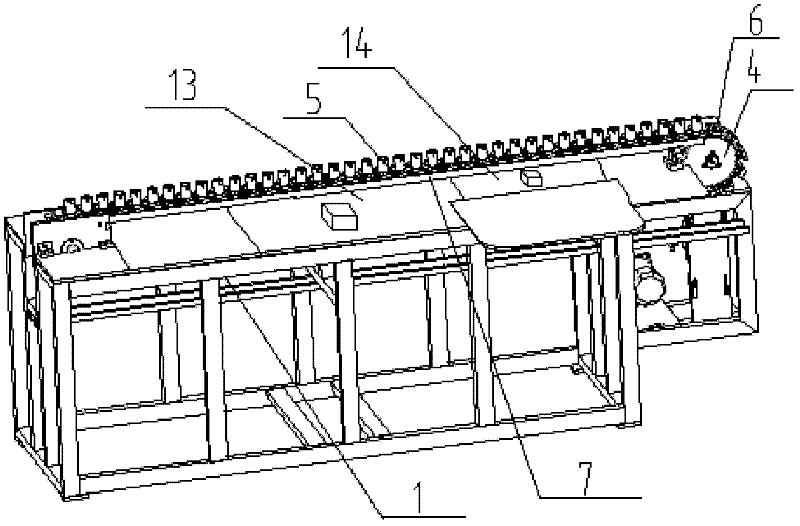

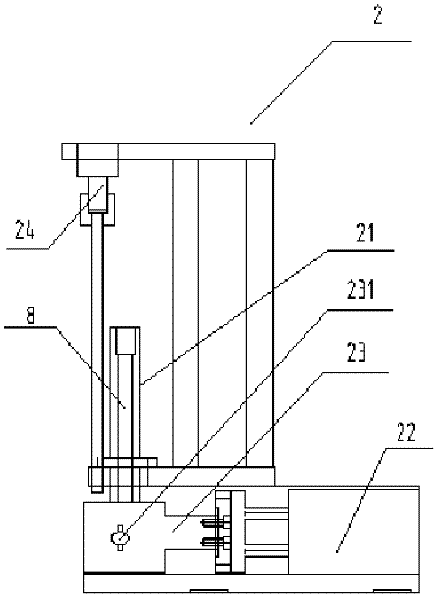

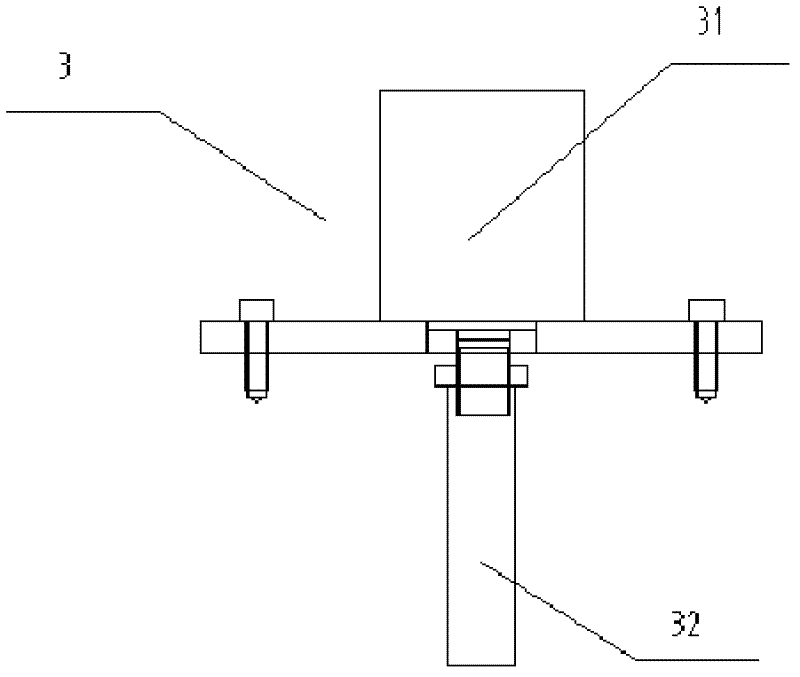

[0020] Embodiment one: if figure 1 As shown, an automatic assembly line for fountain pens includes a workbench 1, two transmission sprockets 4 and an annular transmission chain 5 connecting the two transmission sprockets 4, and the two transmission sprockets 4 are respectively installed at both ends of the workbench 1 , the transmission chain 5 is successively provided with a plurality of clamps 6 for inserting the fountain pen holder, and the transmission track 7 supporting the transmission chain 5 is arranged between the two transmission sprockets 4, and the transmission track 7 is fixed on the workbench 1, and the work A water storage installation station 13 and a water storage pressing station 14 are sequentially arranged on the platform 1, a water storage automatic installation device 2 is arranged on the water storage installation station 13, and a water storage pressing station 14 is provided with Water accumulator automatic compression equipment 3. Such as figure 2 ...

Embodiment 2

[0022] Embodiment two: if Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that a feeding station 11 and an ink filling station 12 are sequentially arranged before the water reservoir installation station 13, and a loading station 12 is sequentially arranged after the water reservoir pressing station 14. Nib station 15, nib nib station 16 and blanking station 17; feeding station 11 is provided with an automatic feeder, ink filling station 12 is provided with an automatic ink filling machine, nib nib station 16 is provided with an automatic Press pen head machine, be provided with automatic blanking machine 9 on blanking station 17, as Figure 5 Shown, automatic blanking machine 9 comprises cylinder support 91, the 4th cylinder 92, the 5th cylinder 93 and the 6th cylinder 94, the cylinder shaft of the 4th cylinder 92 and the cylinder axis of the 5th cylinder 3 are symmetrical, the 4th cylinder 92 and the 6th cylinder 94 The fift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com