Underwater pressure cabin for monitoring marine environment

A marine environment monitoring and pressure chamber technology, applied in underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of high structural strength and sealing performance, system connection interruption, manpower and material resource consumption, etc., to achieve structural strength And high sealing performance, reasonable structure, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

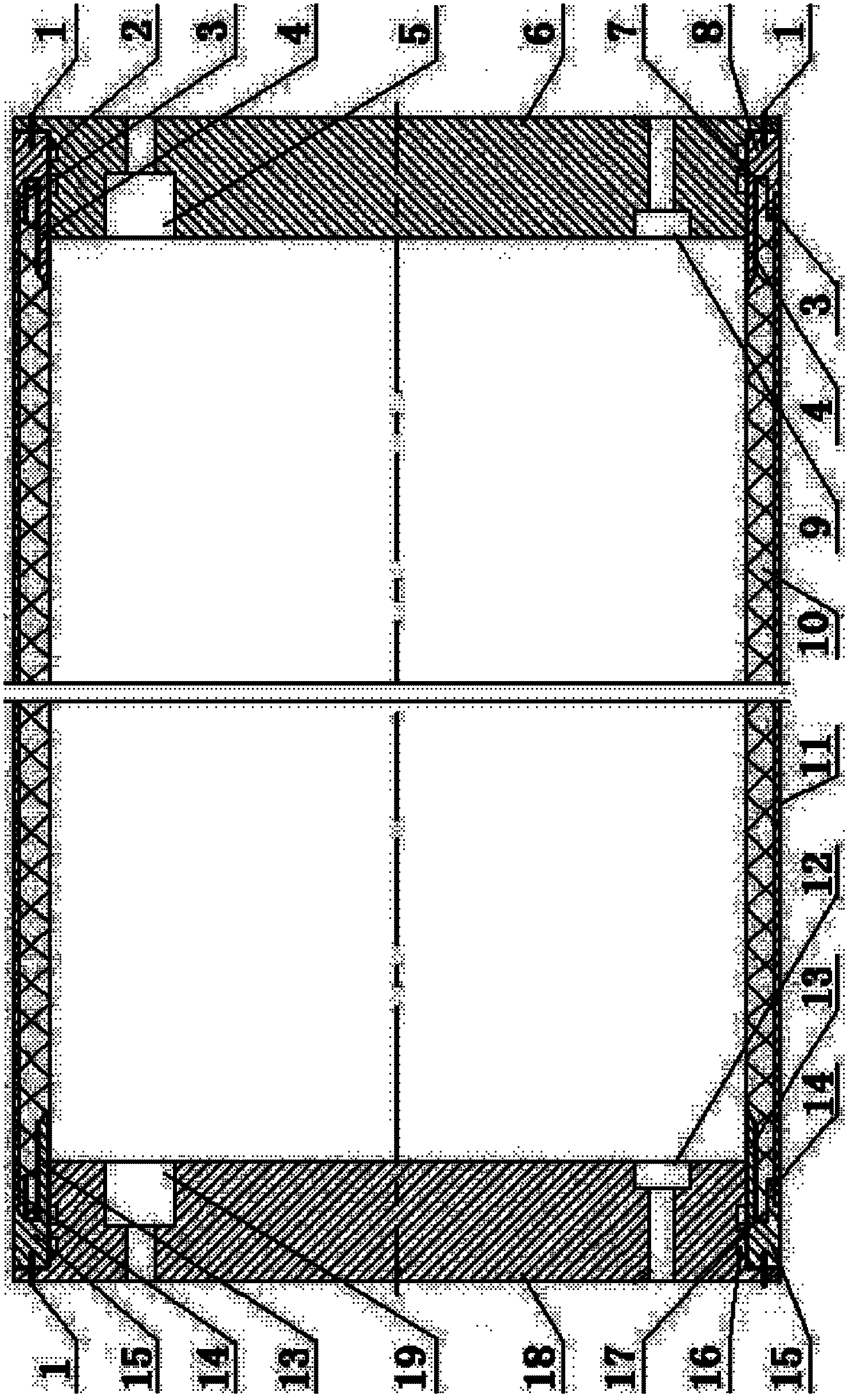

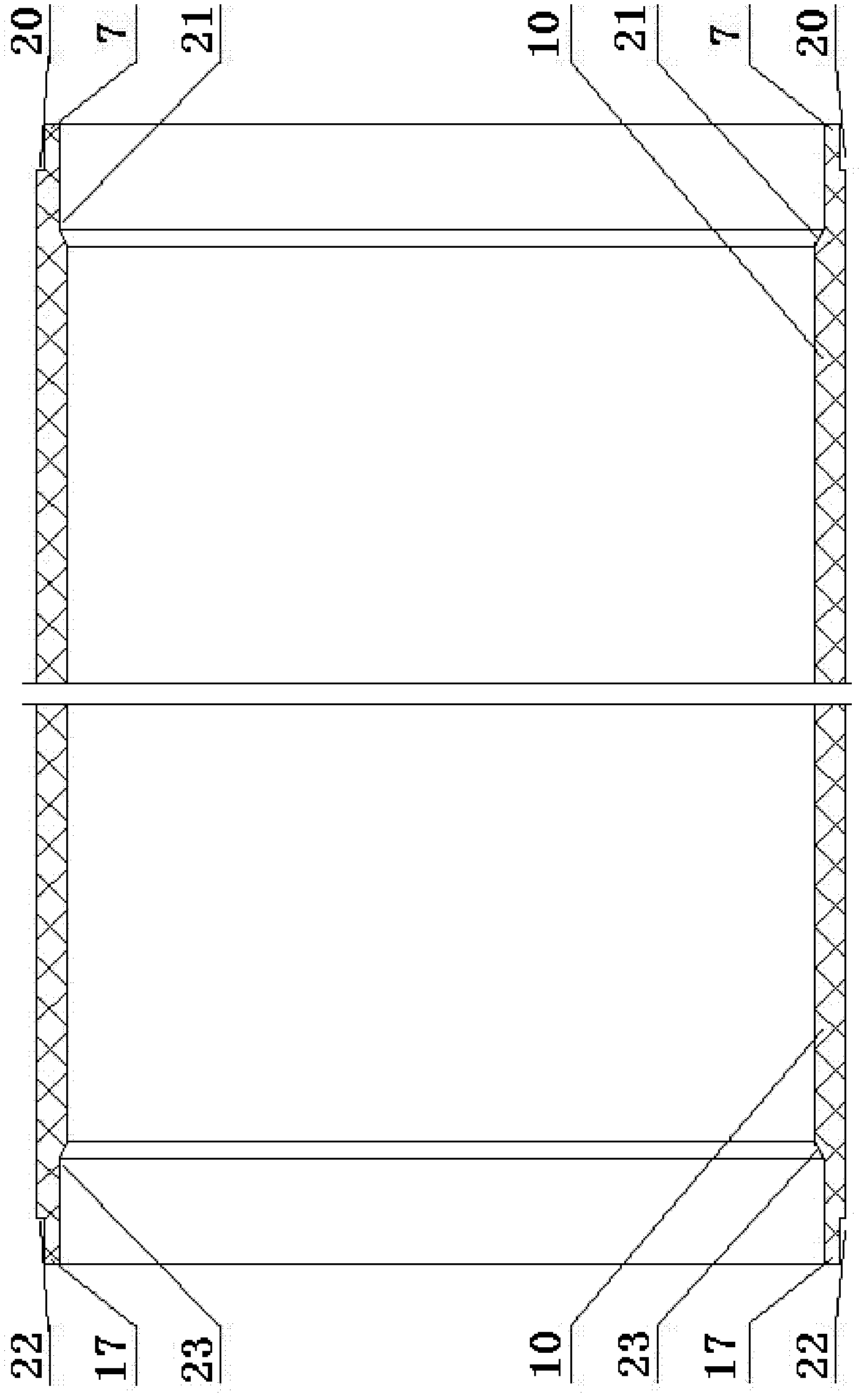

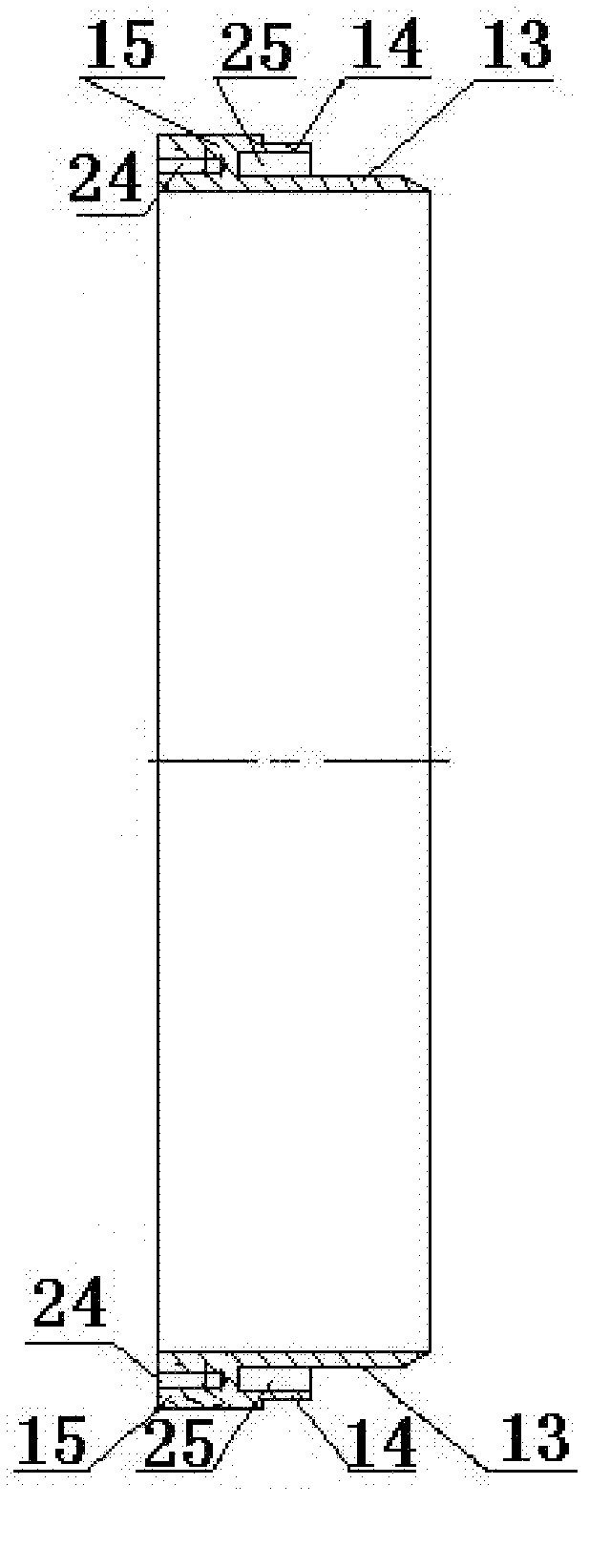

[0020] Specific embodiments of the present invention, such as Figure 1-6 Shown, a kind of marine environment monitoring underwater pressure cabin, comprises underwater pressure cabin body 10, upper sealing end cover 18, lower sealing end cover 6, it is characterized in that:

[0021] A. The upper sealing end cover 18 and the lower sealing end cover 6 are respectively provided with a sealing end ring 15 and a sealing end ring 8, wherein, the middle and both sides of the inner end of the upper sealing end ring 15 are respectively provided with a mounting groove 25 and an inner protrusion The ring wall 13 and the outer convex ring wall 14, and the middle and both sides of the inner end of the corresponding lower sealing end ring 8 are respectively provided with installation grooves 25 of the same size and the inner convex ring wall 4 and the outer convex ring wall 3, and It is integrated with the inner grooves 23 and 21 and the outer grooves 22 and 20 of the upper and lower ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com