Cross-linking agent for profile control and oil displacement for high-temperature oil reservoir, as well as preparation method and application for same

A technology of cross-linking agent and high-temperature oil, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of large dosage, serious volatility of chemical agents, low response ability, etc., and achieve low irritating odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

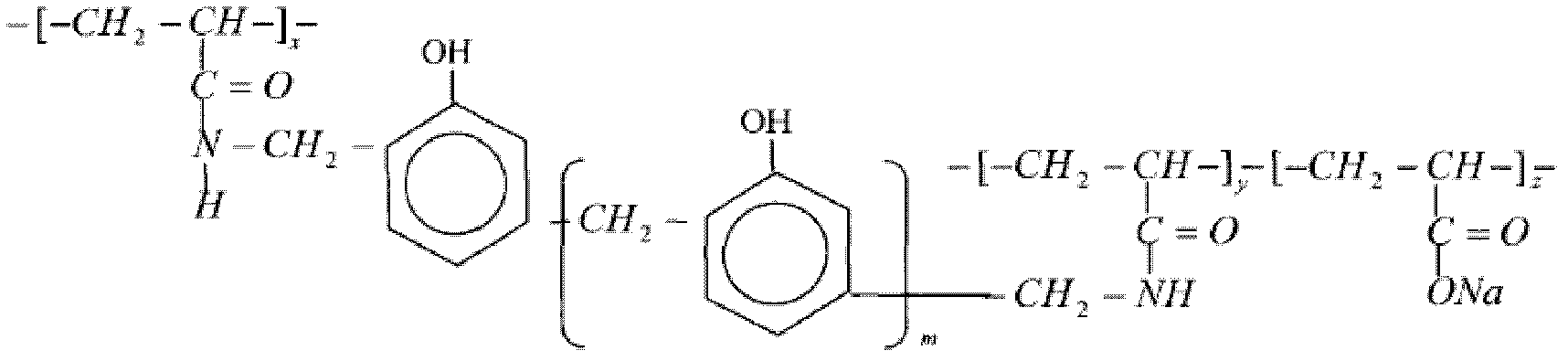

Method used

Image

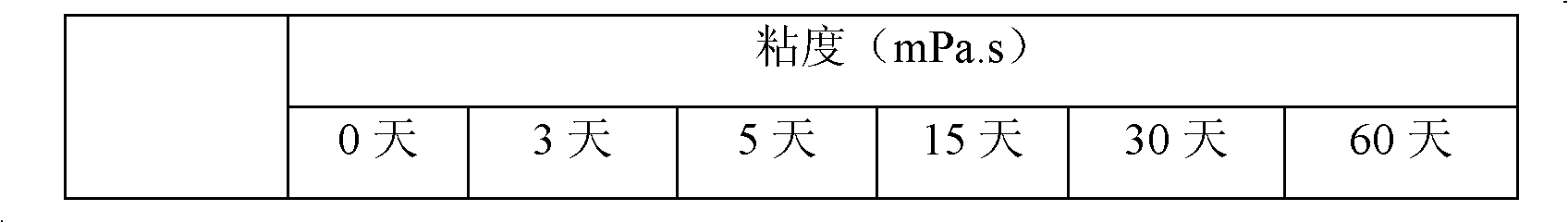

Examples

Embodiment 1

[0027] 1. Synthesis of cross-linking agent for deep control and flooding in high temperature reservoirs

[0028] 1. Prepare raw materials according to the following weight ratio (×10kg)

[0029] Phenol 3, hexamethylenetetramine 2, formaldehyde 2, curing agent 2, catalyst 1

[0030] 2. Put the above raw materials into the reaction kettle together, mix well, heat and keep the temperature at 85±5°C, and carry out the polymerization reaction at this temperature.

[0031] 3. After reacting for 2.5 hours, cool the reaction mixture to room temperature (25°C) to obtain a prepolymer crosslinking agent (ie, a polyhydric phenolic crosslinking agent for high-temperature oil reservoir deep control and flooding).

[0032] 2. Preparation of high-temperature oil reservoir deep control and displacement agent

[0033] 1. Mix clean water and polyacrylamide evenly to prepare a polyacrylamide solution with a concentration of 1000mg / L, that is, add 1000mg of polyacrylamide to every 1L of clean wa...

Embodiment 2

[0038] 1. Synthesis of cross-linking agent for deep control and flooding in high temperature reservoirs

[0039] 1. Prepare raw materials according to the following weight ratio (×10kg)

[0040] Phenol 2.5, Hexamethylenetetramine 2.5, Formaldehyde 1.5, Curing Agent 1.5, Catalyst 1.75

[0041] 2. Put the above raw materials into the reaction kettle together, mix well, heat and keep the temperature at 95±5°C, and carry out the polymerization reaction at this temperature.

[0042] 3. After reacting for 2 hours, the reaction mixture was cooled down to room temperature (25°C) to obtain the product.

[0043] 2. Preparation of high-temperature oil reservoir deep control and displacement agent

[0044] 1. Mix clean water and polyacrylamide evenly to prepare a polyacrylamide solution with a concentration of 800mg / L, that is, add 800mg of polyacrylamide to every 1L of clean water, that is to say, every 1L of clean water contains polyacrylamide The weight is 800mg, and the molecular w...

Embodiment 3

[0048] 1. Synthesis of cross-linking agent for deep control and flooding in high temperature reservoirs

[0049] 1. Prepare raw materials according to the following weight ratio (×10kg)

[0050] Phenol 3.5, hexamethylenetetramine 1.5, formaldehyde 2.5, curing agent 2.5, catalyst 1.25

[0051] 2. Put the above raw materials into the reaction kettle together, mix well, heat and keep the temperature at 80±5°C, and carry out the polymerization reaction at this temperature.

[0052] 3. After reacting for 3 hours, cool the reaction mixture down to room temperature (25° C.) to obtain the product.

[0053] 2. Preparation of high-temperature oil reservoir deep control and displacement agent

[0054] 1. Mix clean water and polyacrylamide evenly, and prepare a polyacrylamide solution with a concentration of 1200mg / L, that is, add 1200mg of polyacrylamide per 1L of clean water, that is to say, every 1L of clean water contains polyacrylamide The weight is 1200mg, and the molecular weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com