Glass fiber reinforced nylon 6-polyethylene terephthalate alloy material and preparation method thereof

A technology of polyethylene terephthalate and glass fiber, which is applied in the field of glass fiber reinforced nylon 6-polyethylene terephthalate alloy material and its preparation, to achieve good impact resistance and maintain dimensional stability The effect of sex and weather resistance

Inactive Publication Date: 2012-07-11

SHANGHAI KINGFA SCI & TECH

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is no report on the preparation of a glass fiber reinforced PA6 / PBT alloy material with excellent comprehensive properties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

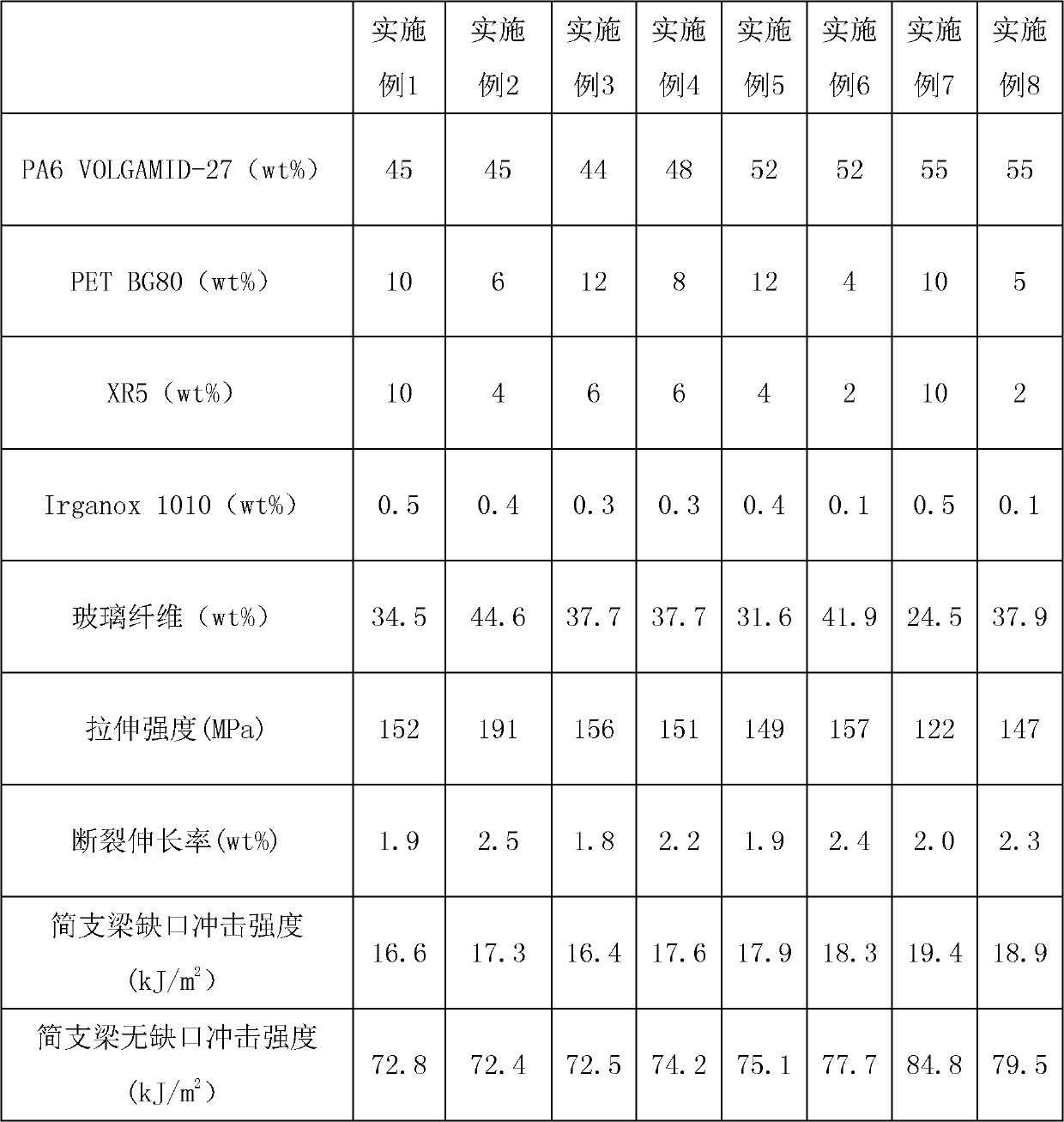

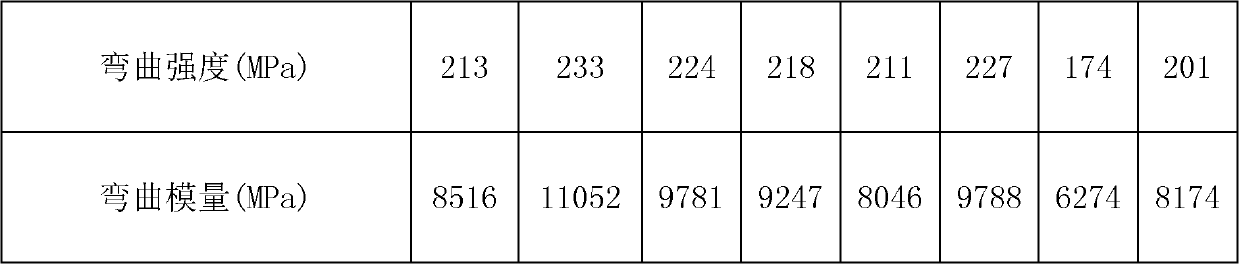

Embodiment 1~7

[0037] The proportioning ratio of preparing compatibilizer is shown in the following table:

[0038] Component

[0039] After mixing each component according to the composition formula in the table, add it to the main cylinder of the 52A (length-to-diameter ratio: 40) twin-screw extruder produced by Ruiya Company, and follow the above steps 1 to 3 to obtain the product of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a glass fiber reinforced nylon 6-polyethylene terephthalate alloy material and a preparation method thereof which can be applied in the industries of electric tools, automobiles, electronics and electrics and the like, and belongs to the technical field of macromolecular materials. The alloy material is prepared from the following raw materials in percentage by weight: 44 to 55 percent of nylon 6 resin (PA6), 4 to 12 percent of polyethylene terephthalate (PET), 24.5 to 44.6 percent of glass fiber, 2 to 10 percent of compatibilizer, and 0.1 to 0.5 percent of antioxidant. By adding the homemade compatibilizer in certain ratio in the glass fiber reinforced nylon 6-polyethylene terephthalate and changing the ratio of the PA6, the PET and the compatibilizer, high impact resistance and toughness can be maintained, and dimensional stability and climate resistance can also be kept.

Description

technical field [0001] The invention relates to a glass fiber-reinforced nylon 6-polyethylene terephthalate alloy material and a preparation method thereof, which can be used in electric tools, automobiles, electrical and electronic industries, and belongs to the technical field of polymer materials. Background technique [0002] Nylon 6 is a kind of engineering plastic with a wide range of uses. It is prepared by the polymerization of caprolactam. Its melting point is 215-225°C, and its service temperature range is -40°C-150°C. Due to the influence of temperature and environment, the performance of ordinary nylon 6 will vary. Substantial changes occur, so its application is greatly limited. Therefore, its comprehensive performance can be significantly improved by filling and strengthening modification. [0003] Polyethylene terephthalate (PET) is currently the most important polyester, commonly known as polyester resin. PET mainly has the following characteristics: good r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/02C08L67/02C08L51/06C08K13/06C08K9/06C08K7/14B29C47/92B29C48/92

CPCB29B9/14B29B7/46B29B7/72B29B7/7461B29B7/90B29B9/06B29B9/12B29C48/04

Inventor 钟鲁张永杨定吉甫

Owner SHANGHAI KINGFA SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com