Etching liquor used for etching microwave dielectric film and preparation method thereof

A technology of microwave medium and etching solution, which is applied in the field of microelectronics, can solve the problems of limiting the application of thin films containing rare earth oxide dielectrics, and achieve the effect of small side etching ratio and clear edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

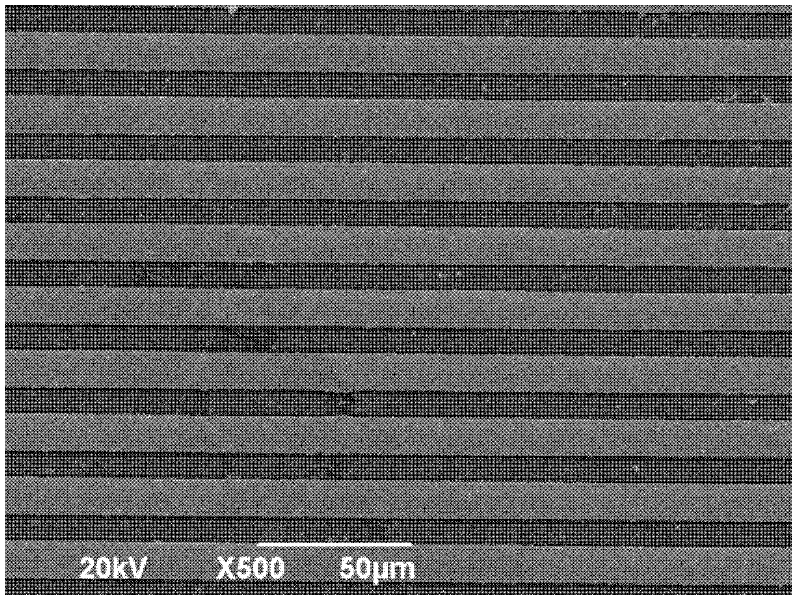

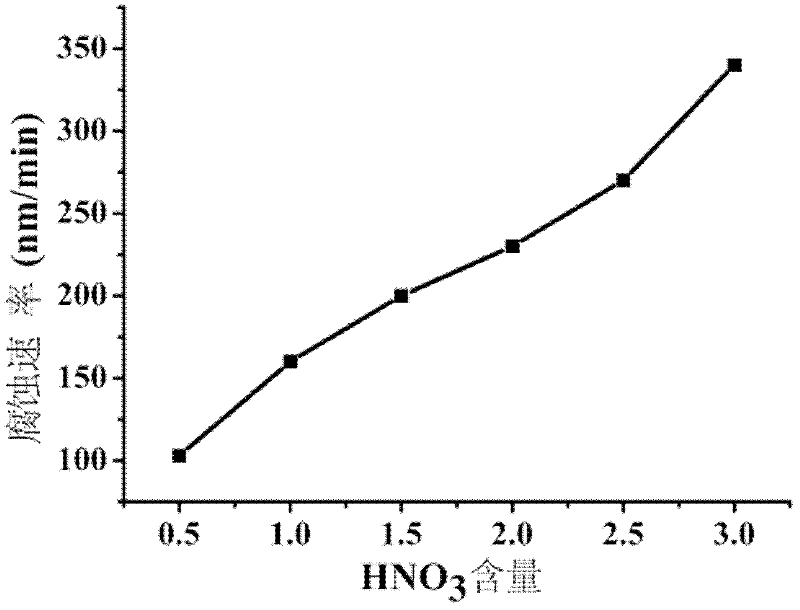

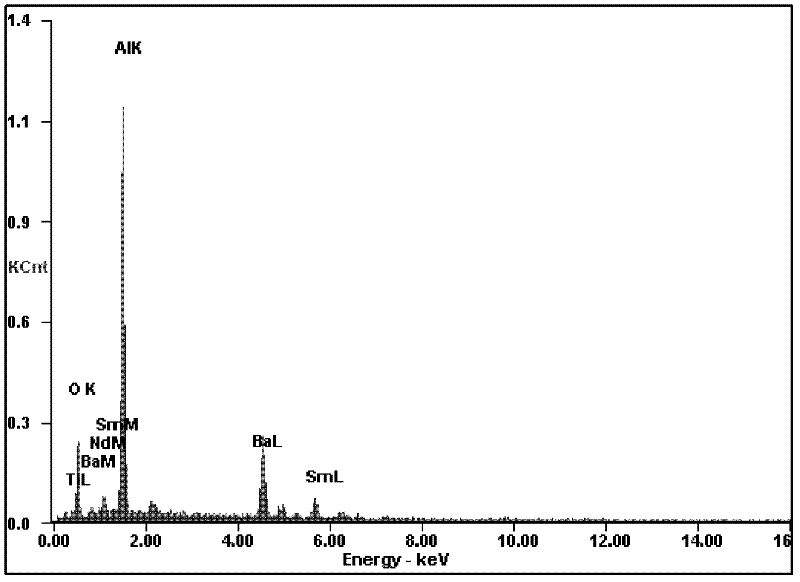

[0018] Using the present invention to etch BaO-Nd 2 o 3 -Sm 2 o 3 -TiO 2 Department of (referred to as BNST) microwave dielectric thin film material. The etching solution raw materials are: hydrofluoric acid (HF); boric acid (H 3 BO 3 ); nitric acid (HNO 3 ); water (H 2 O).

[0019] Preparation ratio and steps:

[0020] The first step is to prepare a HF solution with a mass ratio of 20%, HF:H 2 O=1:1.

[0021] The second step prepares the mass ratio as 12.9% H 3 BO 3 solution, H 3 BO 3 :H 2 O=3:20 (requires 60°C water bath heating).

[0022] The third step is to prepare the fluoboric acid solution (HBF 4 ), 20%HF: 12.9%H 3 BO 3 =1:1.2. put 12.9% H 3 BO 3 Pour the solution into a plastic container filled with 20% HF solution, and stir it with a plastic rod while pouring. A large amount of heat will be released during the reaction, and the plastic container needs to be placed in cold water. After the prepared solution has cooled, remove the plastic contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com