Oil-resistant, cold-resistant double-density shoe rubber outsole and preparation method thereof

A double-density, rubber technology, applied in shoe rubber and its preparation, cold-resistant double-density shoe rubber outsole and its preparation, and oil-resistant fields, can solve the problems of poor processing technology and high content of nitrile rubber, and achieve easy control of the process , good cold resistance and long scorch safety period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

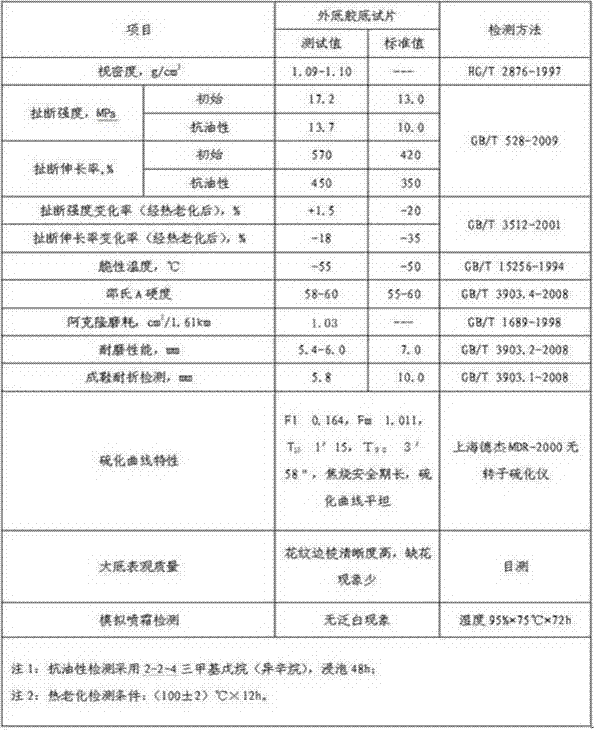

Image

Examples

Embodiment 1

[0069] Example 1 An oil-resistant and cold-resistant double-density shoe rubber outsole and its preparation method

[0070] This embodiment provides an oil-resistant and cold-resistant double-density rubber outsole for shoes and boots and its preparation method. The specific preparation process is carried out in sequence as follows:

[0071] (11) Rubber mastication

[0072] Put 31kg of natural rubber (model SCR-10) into an open mill or an internal mixer for masticating, and after the plasticity reaches 0.45-0.50, natural rubber A1 with satisfactory plasticity is obtained;

[0073] (12) Compounding and refining

[0074] Put 27kg of butadiene rubber (model BR9000) and 43 kg of nitrile rubber (model JSR N240S) into the open mixer or internal mixer together with A1 and knead until the rubber cross-section is uniform , after being flat and smooth, C1 is obtained;

[0075] (13) Compound mixing

[0076] C1 and middle material [4kg zinc oxide, 2kg stearic acid, anti-aging agent (0...

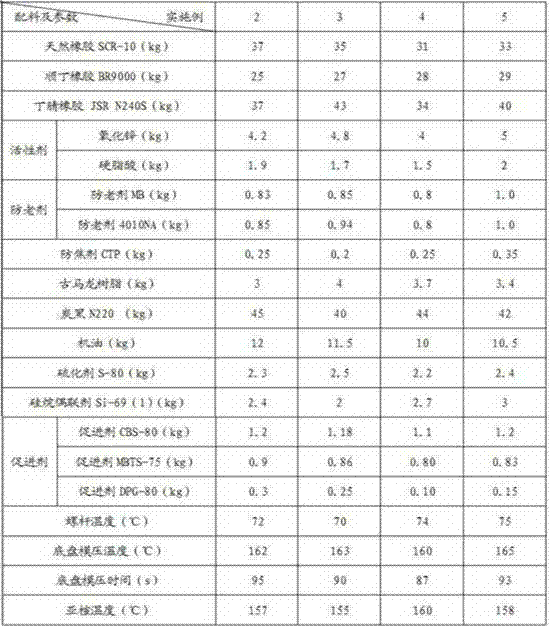

Embodiment 2-5

[0083] Example 2-5 Oil-resistant, cold-resistant double-density shoe rubber outsole and preparation method thereof

[0084] This example is an oil-resistant and cold-resistant double-density rubber outsole for shoes and boots. Its preparation method is similar to that of Example 1, except that the ingredients of the product and the process parameters in the preparation process are different. See the table below for details.

[0085] Table 1 Formula and process parameters of oil-resistant and cold-resistant double-density rubber outsole for shoes and boots

[0086]

[0087] Explanation: The engine oil in Example 2-5 is added in two times, and the timing of addition is referred to in Example 1. The weight ratio of the two times is 2:1, that is, 2 / 3 of the total amount is added for the first time, and the rest is added for the second time. quantity.

[0088] The preparation method of the above embodiment is simple, the process is easy to control, and the processing performanc...

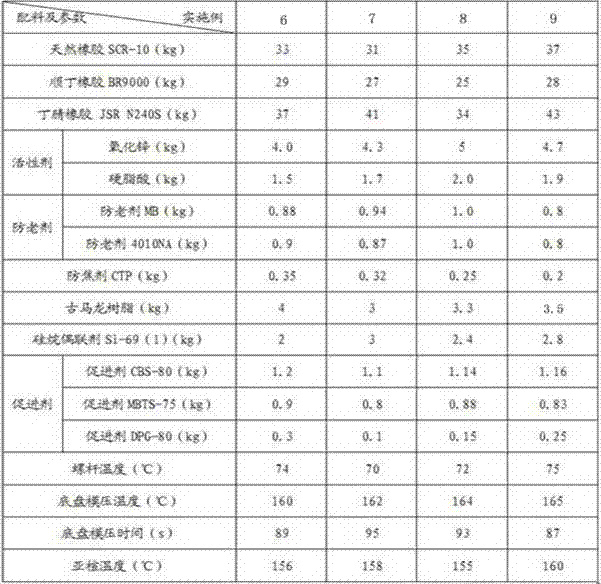

Embodiment 6-9

[0089] Example 6-9 Oil-resistant and cold-resistant double-density shoe rubber outsole and its preparation method

[0090] This embodiment is respectively a kind of oil-resistant, cold-resistant double-density rubber outsole for shoes and boots, and its ingredient composition is shown in Table 2.

[0091] Table 2 The formula and process parameters of oil-resistant and cold-resistant double-density rubber outsole for shoes and boots

[0092]

[0093] The preparation method of the oil-resistant and cold-resistant double-density shoe rubber outsole provided in Examples 6-9 is carried out in sequence according to the following steps:

[0094] (I) Rubber mastication

[0095] Put the natural rubber into an open mill or an internal mixer for masticating, and after the plasticity reaches 0.45-0.50, natural rubber a with satisfactory plasticity is obtained;

[0096] (Ⅱ) Compound mixing

[0097] Put the nitrile rubber and butadiene rubber into the open mill or internal mixer toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com