Water-cooled furnace lid for refined-smelting ladle furnace, and slag removal method of dust-proof flue of water-cooled furnace lid

A technology of a ladle refining furnace and a water-cooled furnace cover, which is applied in the field of slag removal of dust removal flue and water-cooled furnace cover of ladle refining furnace, can solve the problems of fluctuation of production organization, direct impact of economic production, and long time for resumption of production, etc. Quick cleanup, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

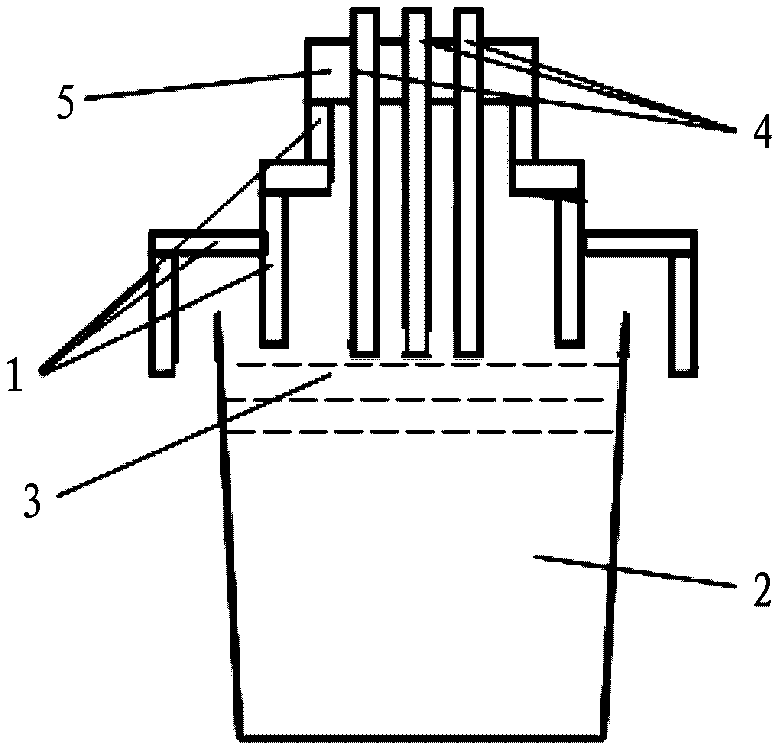

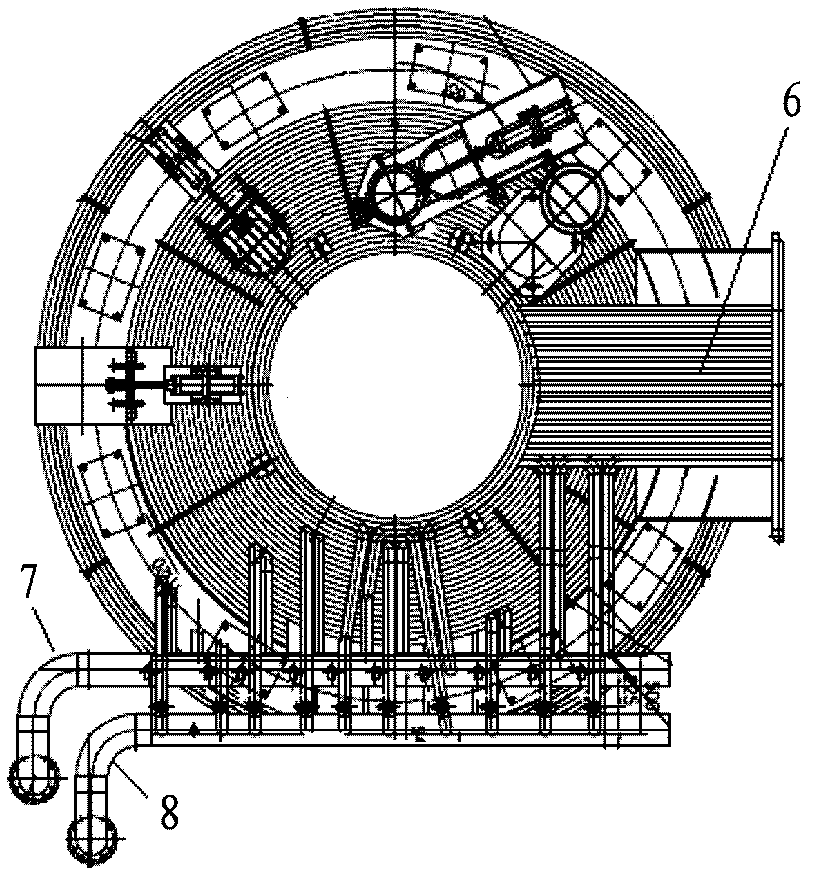

[0020] Hereinafter, the water-cooled furnace cover of the ladle refining furnace and the slag removal method of the dust removal flue of the ladle refining furnace of the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

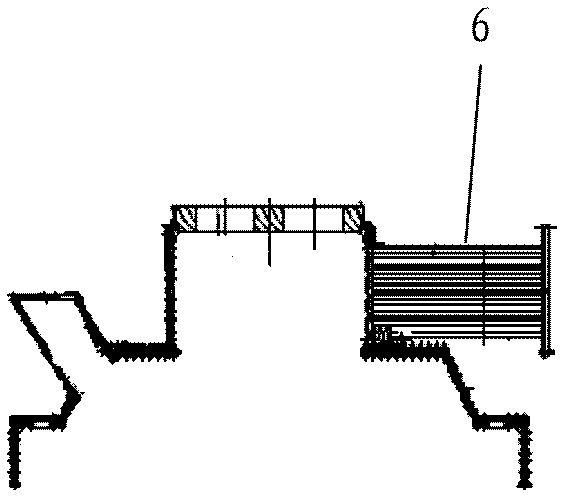

[0021] Figure 3A Shows a schematic top view of a water-cooled furnace cover of a ladle refining furnace according to an exemplary embodiment of the present invention, Figure 3B It shows a schematic front view of a water-cooled furnace cover of a ladle refining furnace according to an exemplary embodiment of the present invention.

[0022] Such as Figure 3A with Figure 3B As shown, the water-cooled furnace cover 1 of the ladle refining furnace according to the exemplary embodiment of the present invention includes a dust removal flue 6, one end of which is connected to the water-cooled furnace cover 1 and communicates with the furnace space of the ladle refining furnace, The other end of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com