Concave-convex loop-cutting computer jacquard machine

A computerized jacquard machine and driving motor technology, applied in textiles and papermaking, weft knitting, knitting and other directions, can solve the problems of waste of raw materials and serious environmental pollution, and achieve the effect of reducing sewage discharge, reducing environmental pollution and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

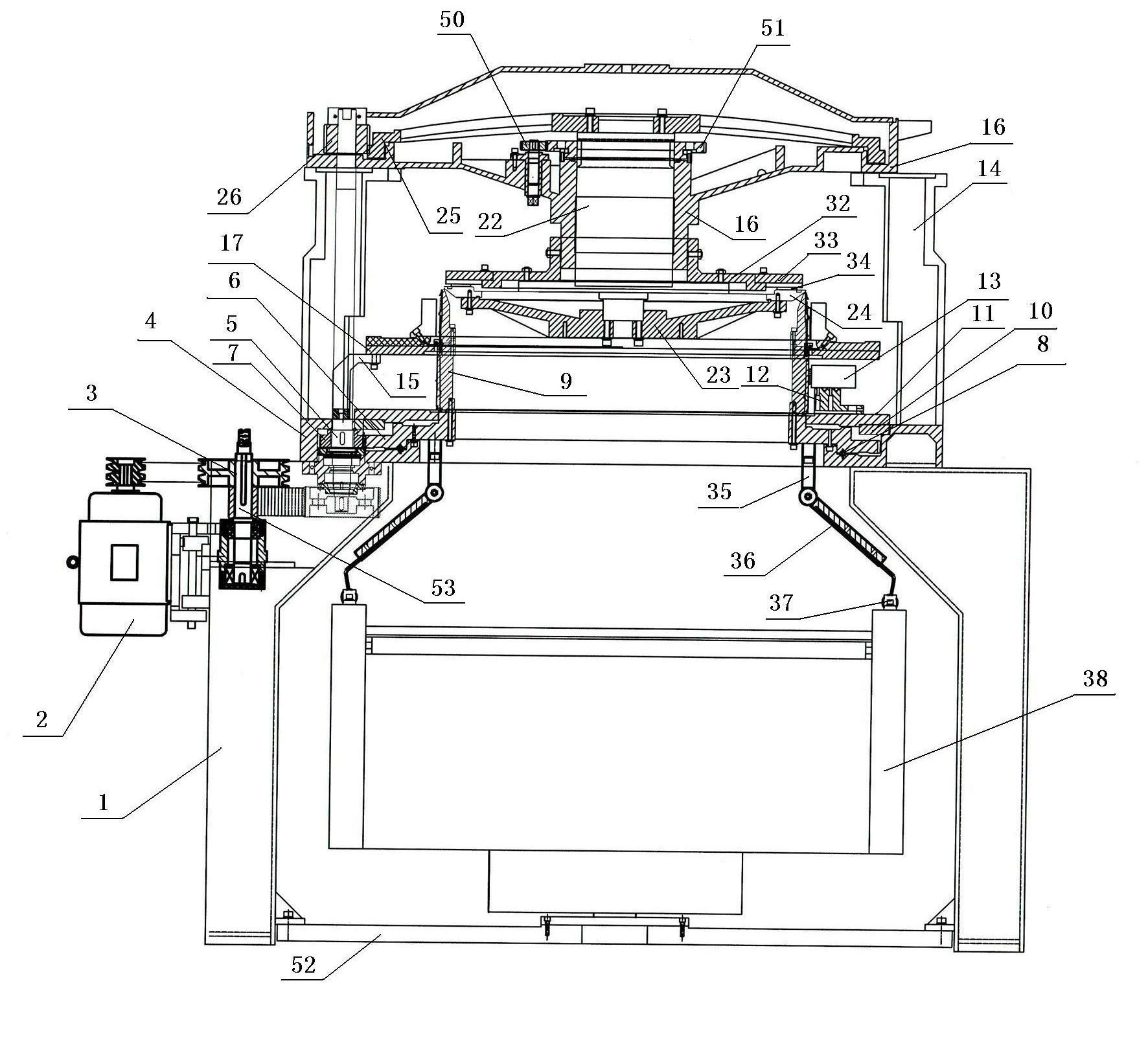

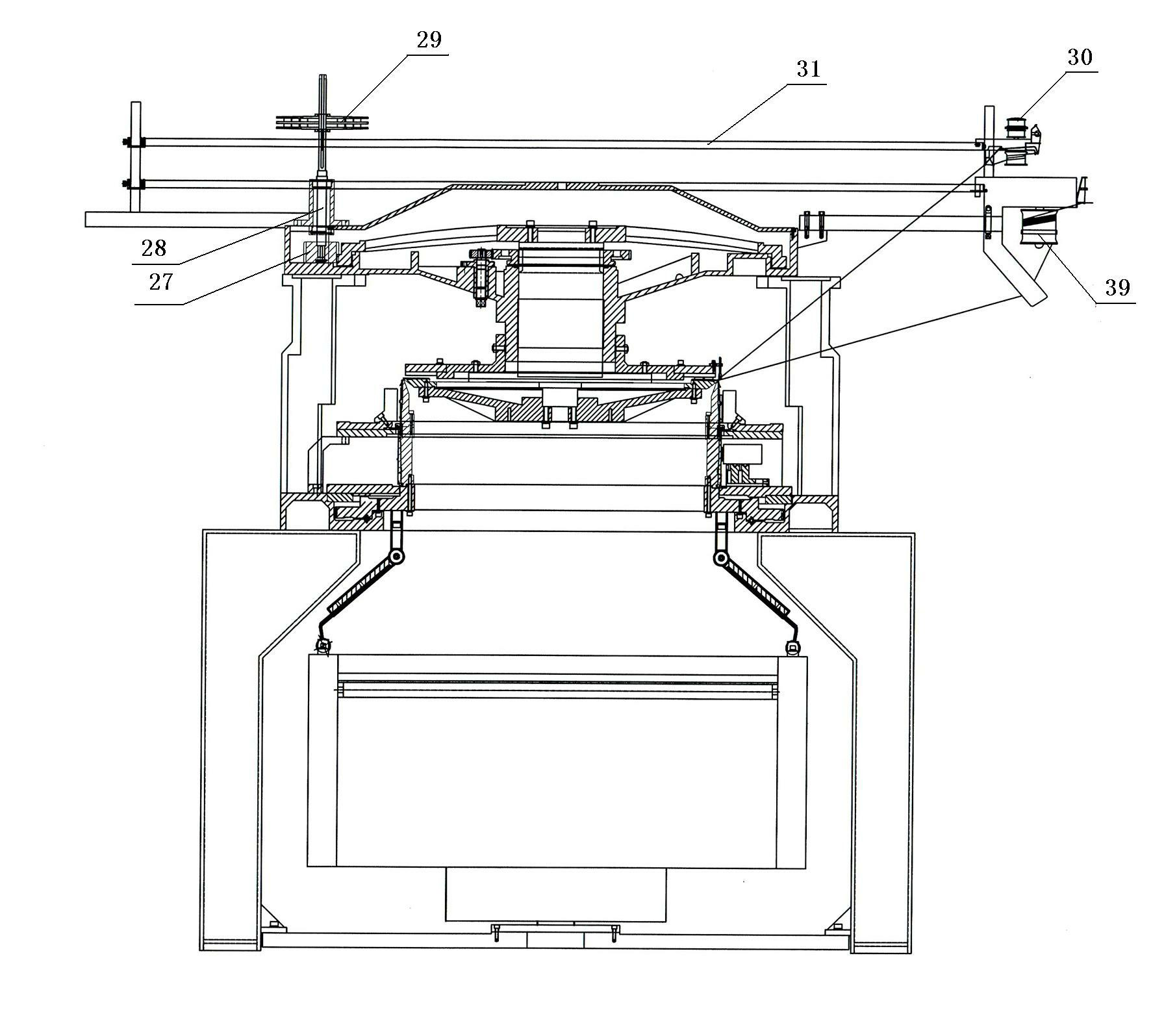

[0040] Embodiment 1, with reference to Figure 1-4 , a computer jacquard machine with concave and convex ring cutting,

[0041] It includes a frame 1, on which a driving motor 2 is connected; on the frame 1, a large plate 4 is also fixed;

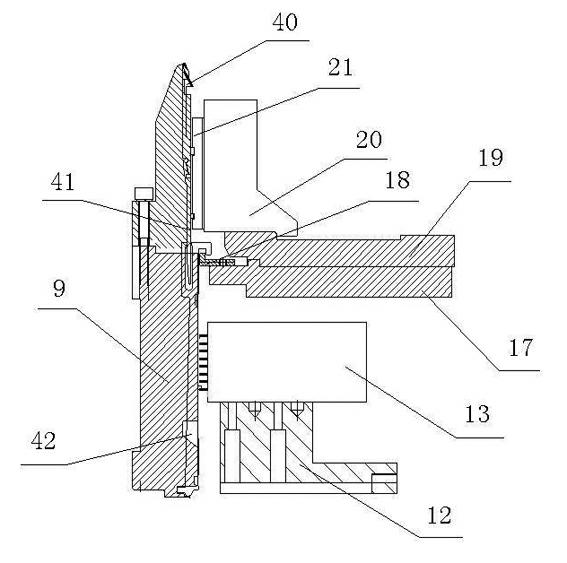

[0042] The driving motor 2 is connected with the main transmission shaft 5 through the transmission mechanism 3, and the main transmission shaft 5 is fixed on the bottom surface of the large disk 4 through the main transmission bearing seat. The key fit is installed on the main transmission shaft 5, and the steel wire runway 8 is installed between the large plate 4 and the large plate gear 6. The large plate gear 6 is driven by the main transmission gear 7 meshing with it, and rotates in the large plate 4;

[0043] The lower needle cylinder 9 is fixed on the large plate gear 6, the large plate 4 is fixed with a washer 10, the washer 10 is fixed with a bottom ring 11, the bottom ring 11 is provided with a needle selector bracket 12, and the...

Embodiment 2

[0049] Embodiment 2, in the concave-convex ring cutting computer jacquard machine described in embodiment 1: a small hair height adjustment shaft is provided on the big tripod 16, and a hair height adjustment gear 50 is connected to the hair height adjustment small shaft, and the hair height adjustment gear 50 meshes with the barrel lifting gear 51, and the barrel lifting gear 51 is located at the top of the barrel 22.

Embodiment 3

[0050] Embodiment 3, in embodiment 1 or 2 described concave-convex ring cutting computerized jacquard machine: described frame 1 comprises supporting main foot and auxiliary foot, main foot and auxiliary foot center are symmetrically fixed under the large plate 4, under the main Pin is connected with trident 52 with foot bottom, is fixed with motor support on main pin, and motor support can cross bearing pin and connect motor base, and drive motor 2 is fixed on the motor base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com