Continuous cotton pulp washing and bleaching process

A cotton pulp and process technology, applied in the field of washing and bleaching processes, to achieve high product quality, reduce production water consumption, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

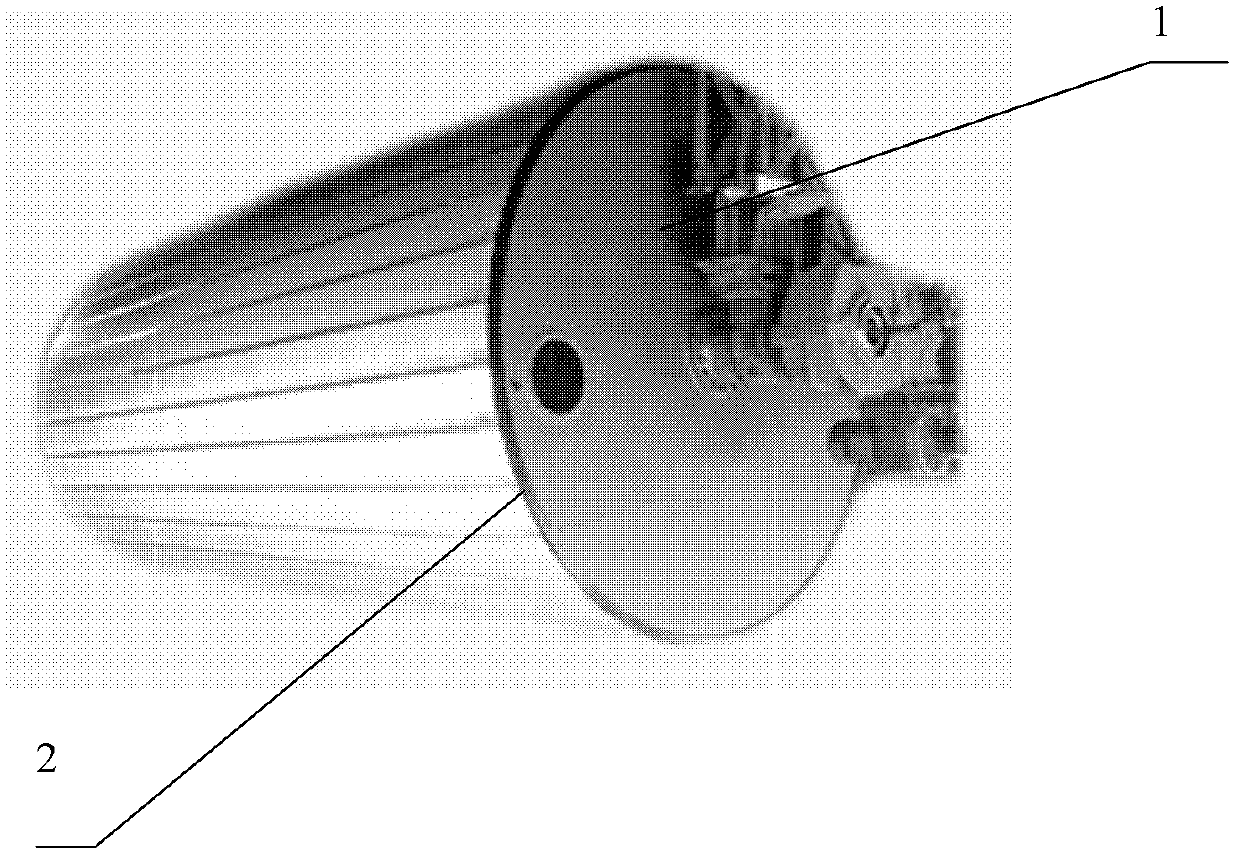

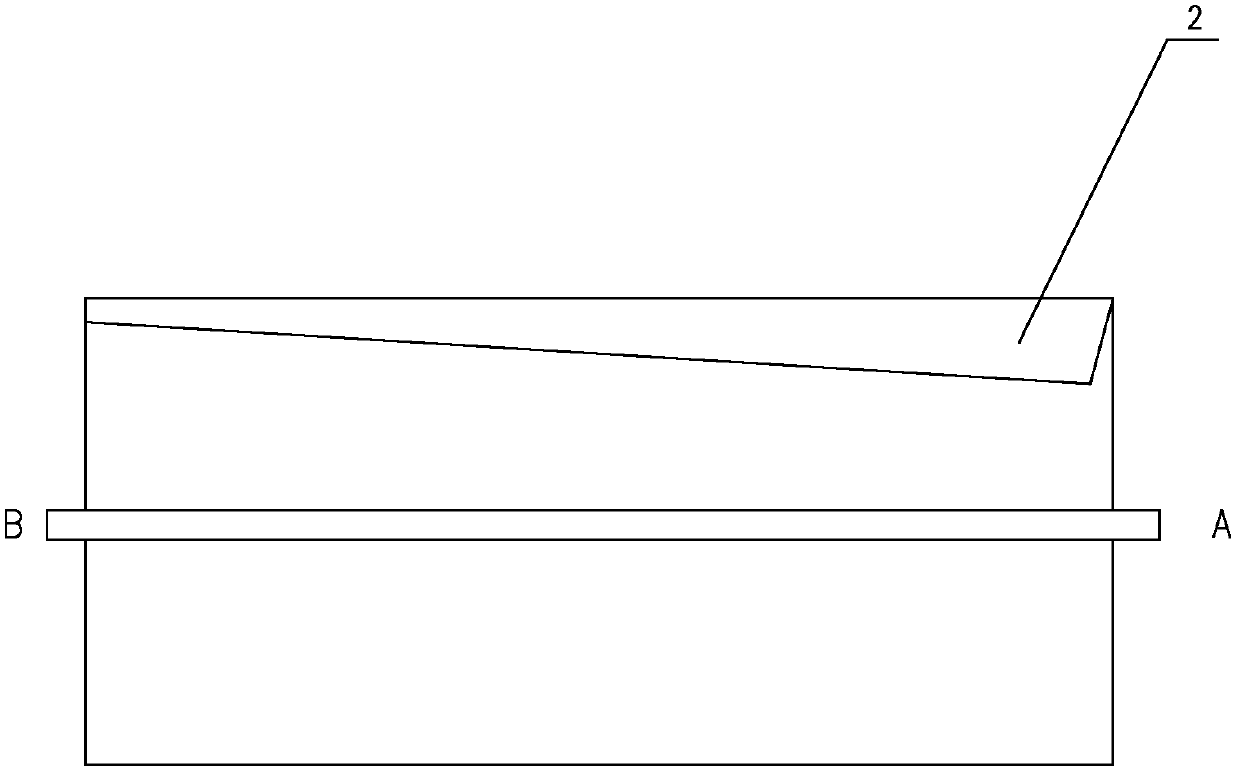

[0028] The cooked cotton pulp enters the buffer pulp tower, and after passing through the concentration regulator, it is pumped to the high-concentration desander for preliminary desandering. After desanding, the pulp is beaten by a large taper refiner, and the beating degree is 28-32° SR, then further adjust the concentration to 0.5wt%, and then continuously enter 4 sets of vacuum washing machines in series for washing. The finished pulp enters the separately set vacuum pulp washing machine for further washing and concentration; the washing water produced at this time can be directly used to adjust the concentration of the pulp before entering the low-concentration desander through the closed pipeline, so as to realize the circulation of water resources use. Among them, the drum vacuum pulp washer, the key equipment in the process, has the following main structure: the filtrate flow channel 2 of the drum 1 of the pulp washer is gradually inclined from the transmission side B ...

Embodiment 2

[0032] The cooked cotton pulp enters the buffer pulp tower, and after passing through the concentration regulator, it is pumped to the high-concentration desander for preliminary desandering. After desanding, the pulp is beaten by a large taper refiner, and the beating degree is 28-30° SR, then further adjust the concentration to 1.5wt%, and then continuously enter 5 sets of vacuum washing machines in series for washing. The slurry enters the separately set vacuum pulp washing machine for further washing and concentration; the washing water produced at this time can be directly used to adjust the concentration of the slurry before entering the low-concentration desander through the closed pipeline, so as to realize the recycling of water resources . Among them, the drum vacuum pulp washer, the key equipment in the process, has the following main structure: the filtrate flow channel 2 of the drum 1 of the pulp washer is gradually inclined from the transmission side B to the non...

Embodiment 3

[0036] The cooked cotton pulp enters the buffer pulp tower, and after passing through the concentration regulator, it is pumped to the high-concentration desander for preliminary desandering. After desanding, the pulp is beaten by a large taper refiner, and the beating degree is 30-32° SR, then further adjust the concentration to 2wt%, and then continuously enter 4 sets of vacuum pulp washing machines in series for washing, and the washed pulp enters the middle pulp tank, and after adjusting the concentration to 1.5wt%, enters the low-consistency desander for further purification, after purification The slurry enters the separately set vacuum pulp washing machine for further washing and concentration; the washing water produced at this time can be directly used to adjust the concentration of the slurry before entering the low-concentration desander through the closed pipeline, so as to realize the recycling of water resources . Among them, the drum vacuum pulp washer, the key ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com