Patents

Literature

35results about How to "Product quality is high and stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation process of high-activity anti-condensation calcium hydroxide

ActiveCN108911535AHigh purityQuality improvementSievingGas current separationCalcium hydroxideFiltration

The invention discloses a preparation process of high-activity anti-condensation calcium hydroxide. The preparation process comprises the following steps: (1) high-temperature calcination treatment; (2) crushing screening of calcium oxide stones; (3) digestion reaction; (4) filtration and dewatering treatment; (5) baking drying; (6) screening and filtration treatment. The invention provides a technical scheme of the preparation process of the high-activity anti-condensation calcium hydroxide. An integrated process production process is automatically controlled, the labor strength of workers islow, the operation security performance is also improved, and technical risks are avoided; moreover, a calcium hydroxide product prepared by adopting the preparation process has the advantages of high quality and stability, energy consumption loss during production is low, the yield of the product is high, the purity is high, the production cost is effectively reduced, and the economic benefit isimproved.

Owner:叶萍

A kind of preparation technology of water-soluble ginkgo leaf extract

ActiveCN102293793AGood water solubilityGood process stabilityNervous disorderGinkgophyta medical ingredientsBiotechnologyGinkgo Biloba Leaf Extract

The invention relates to a water-soluble ginkgo leaf extract and its preparation technology, The method of the invention comprises: taking common ginkgo biloba as a raw material, mixing with acetone and extracting, concentrating, diluting by adding water, cryoprecipitating, filtering, performing a gradient elution to a filtrate through macroporous adsorption resin, carrying out an alcohol precipitation by ethanol with high purity, water extraction and cryoprecipitating, concentrating, drying to obtain the water-soluble ginkgo leaf extract, wherein the content of total flavonol glycoside is greater than or equal to 27%; the content of lactone content is 9%-12%, wherein the content of Terpene Lactones A is greater than or equal to 2.1%, the content of Terpene Lactones B is greater than or equal to 0.9%, the content of Terpene Lactones C is greater than or equal to 1.2%, and the lactone ratio of GA:GB:GC is close to 7:3:4; the water-solubility is greater than and equal to 10%; the ginkgolic acid is less than and equal to 1ppm, which can be taken as a raw material used for injection. The invention has the advantages of simple production technology, high and stable product quality, high finished product yield, low cost and good economic benefit.

Owner:ZHEJIANG CONBA PHARMA

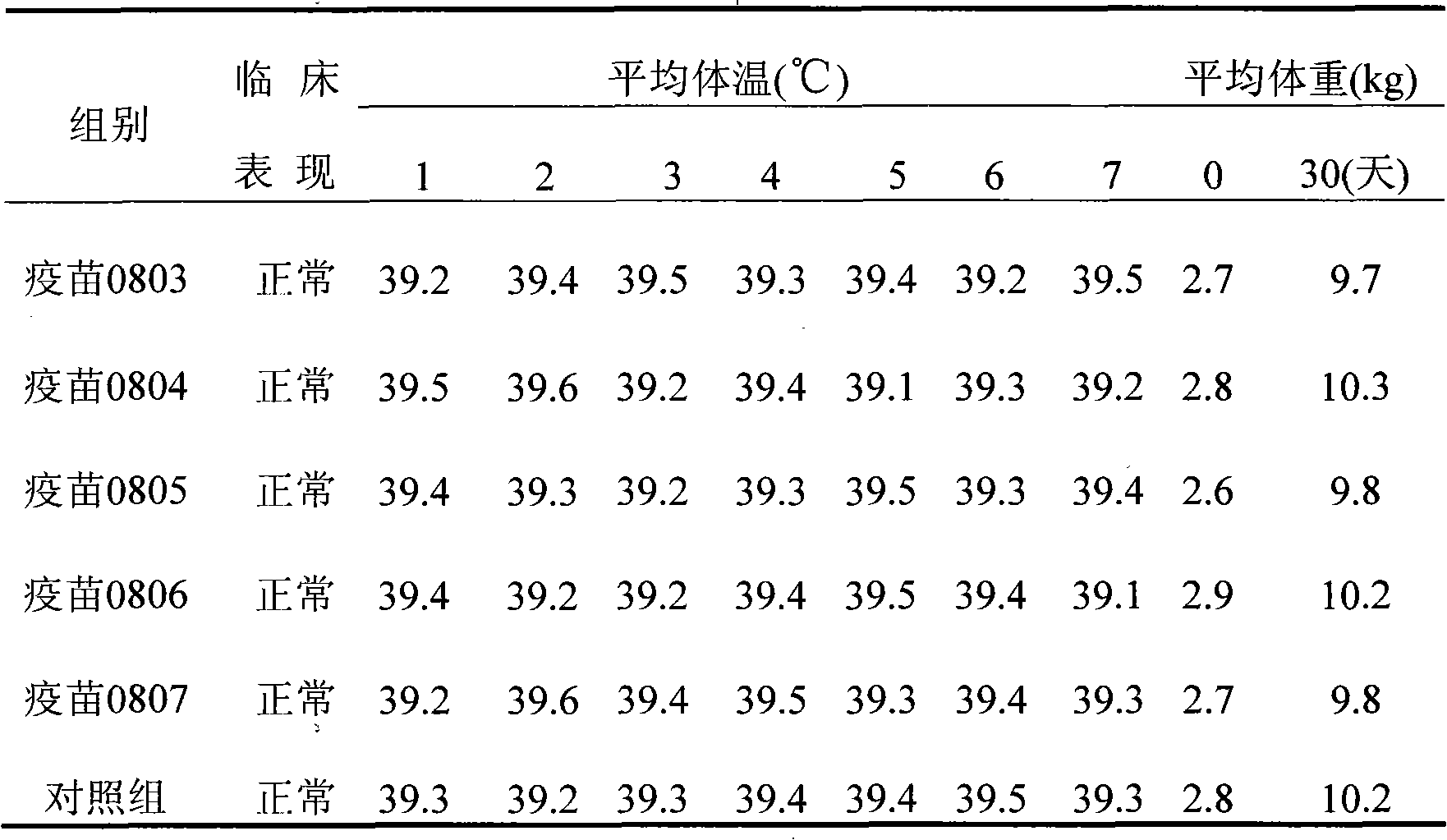

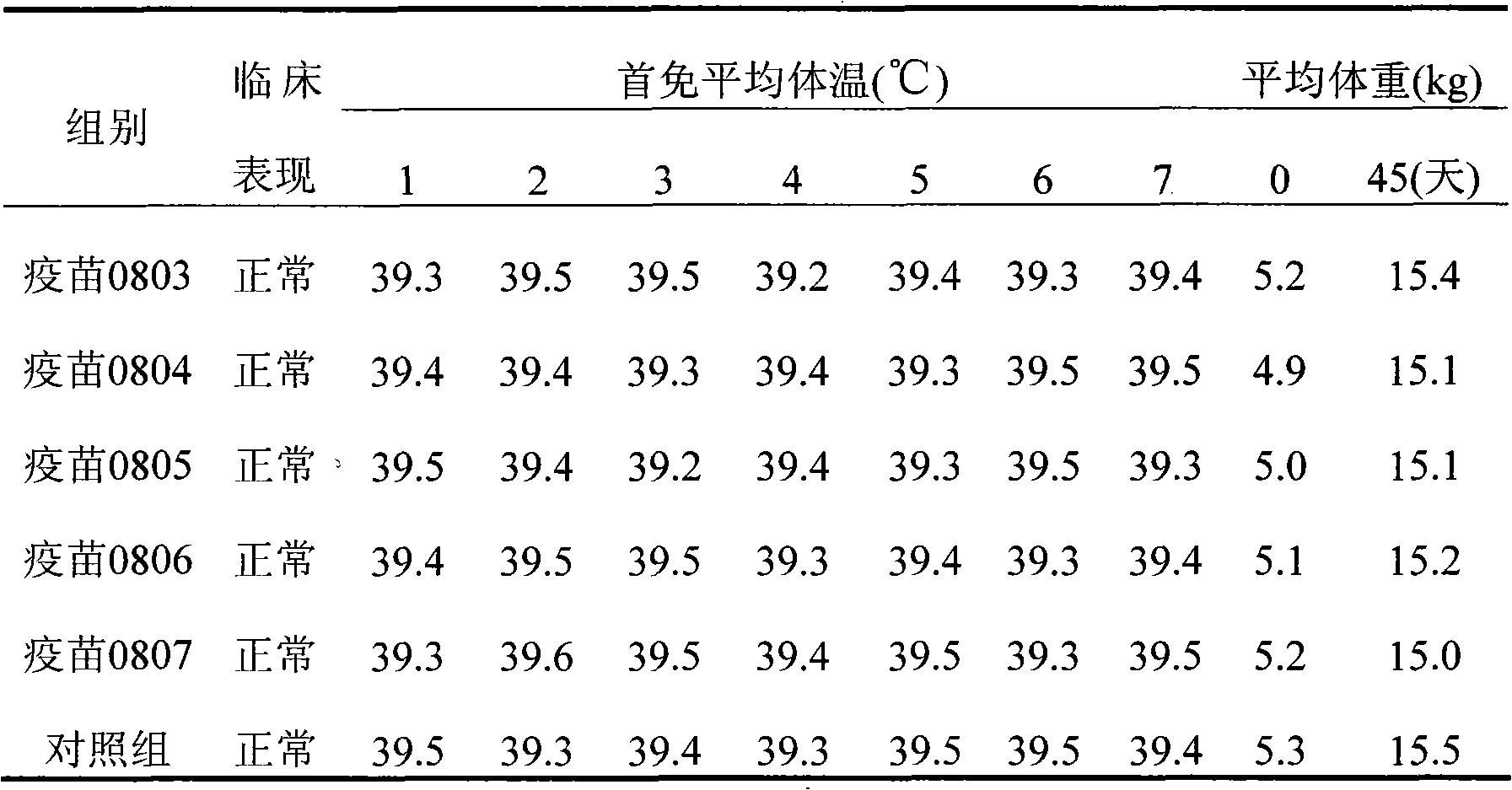

Preparation method for vaccine of porcine circovirus II

InactiveCN101773667AHigh poison priceExpand production scaleViral antigen ingredientsBiological material analysisAdjuvantHigh density

The invention discloses mass production of inactivated vaccine of porcine circovirus II (PCV2) and a preparation method thereof. The preparation method comprises the following technical steps: (1) high-density culture of cells for vaccine preparation; (2) reproduction of venom for vaccine preparation; and (3) addition of adjuvant to prepare the inactivated vaccine. Compared with the prior art, the invention has the advantages that the virus yield is high, the virus titer is high, the production scale is large, the yield of a single batch is high, the production cost is relatively low, the product quality is high and stable, the operation is convenient, the operation space is small, the technological parameters are controlled accurately and the like. The inactivated vaccine has high safety, can induce pig bodies to generate immune protection and fully satisfies the national biological product standards.

Owner:PU LIKE BIO ENG

Vacuum infusion machining method for weather-resistant fiberglass reinforced plastics (FRP) products

The invention provides a vacuum infusion machining method for weather-resistant fiberglass reinforced plastics (FRP) products. The method comprises the steps of preparing a mould - applying gel coat - laying at least three layers of fiberglass - laying an isolating membrane with holes - laying and arranging guide pipes - laying a guide net - laying a vacuum bag - vacuum pumping - resin leading-in - demoulding; the laying sequence of the guide pipes and the guide net in the traditional vacuum infusion machining method is changed, and the inside surfaces of the FRP products prepared are free of pipe pressure traces; the gel coat resin prepared is made of raw material constituents which are excellent in performance and able to coordinate with each other, and the gel coat prepared is excellent in weatherability and able to prevent early aging of the FRP products in high temperature, severe cold or other environments; the basic resin in the invention is able to infiltrate the fiberglass properly, and the FRP products prepared finally is high in quality and stability, excellent in weatherability, and applicable for outdoor use.

Owner:CHONGQING HAIQING NEW MATERIAL

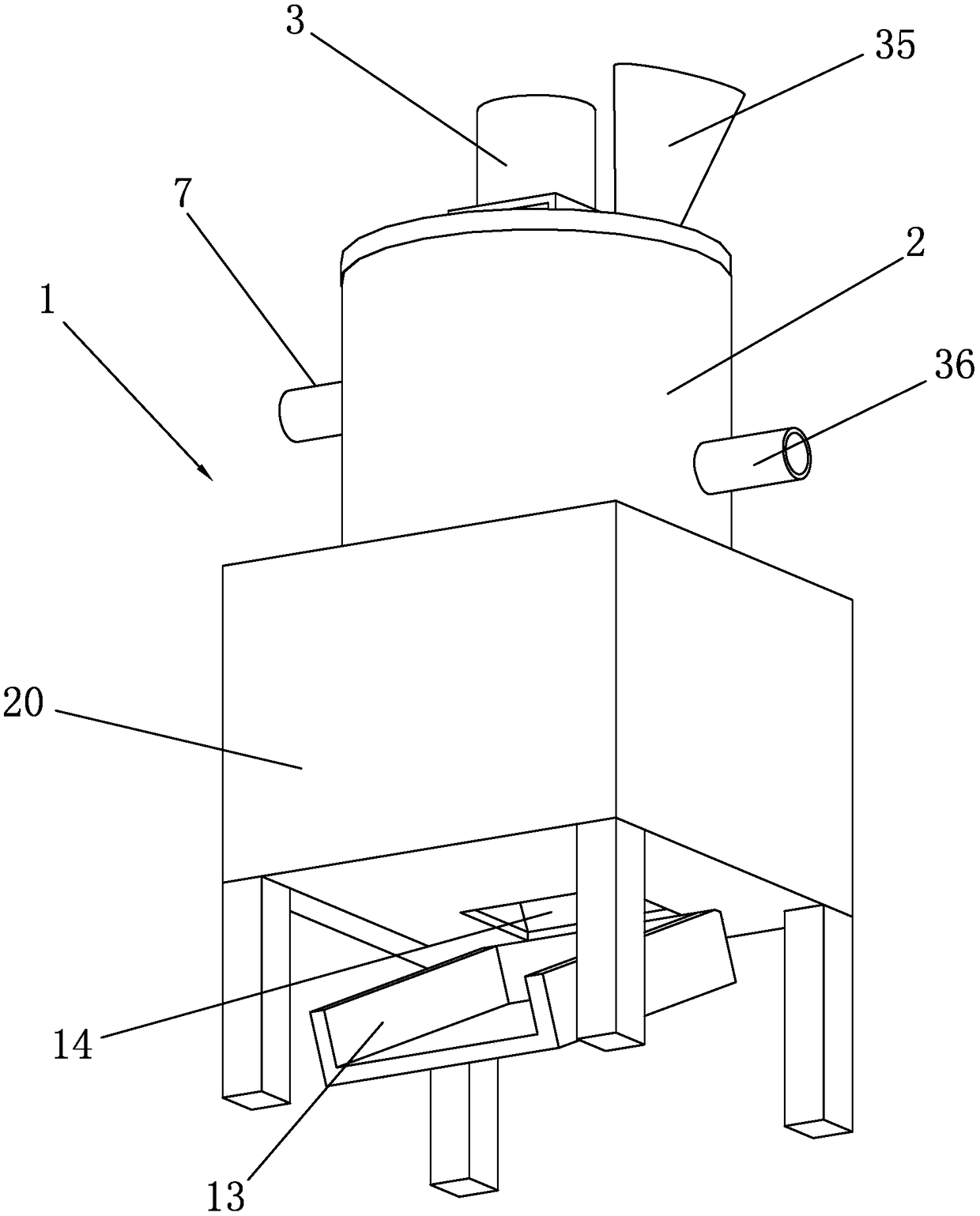

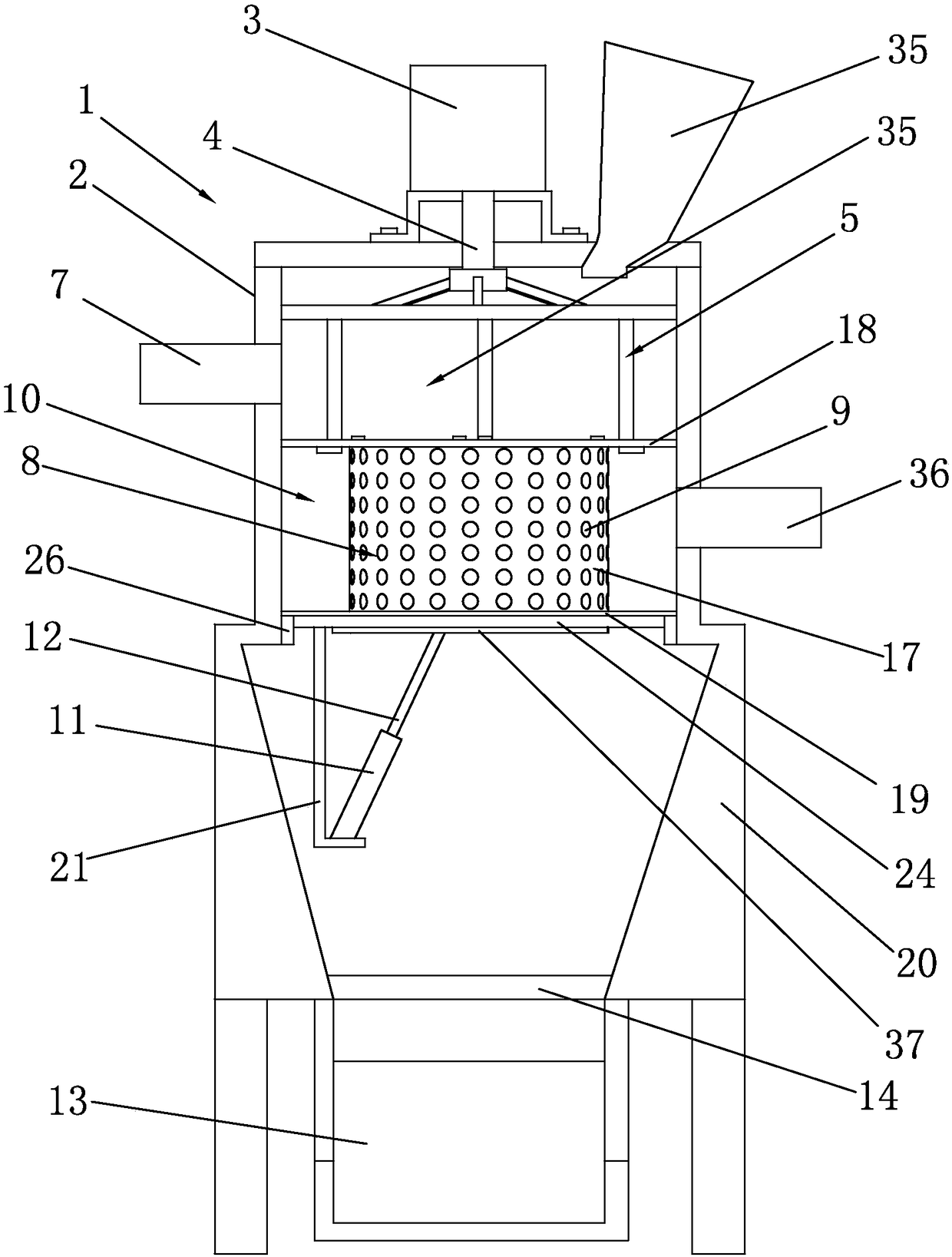

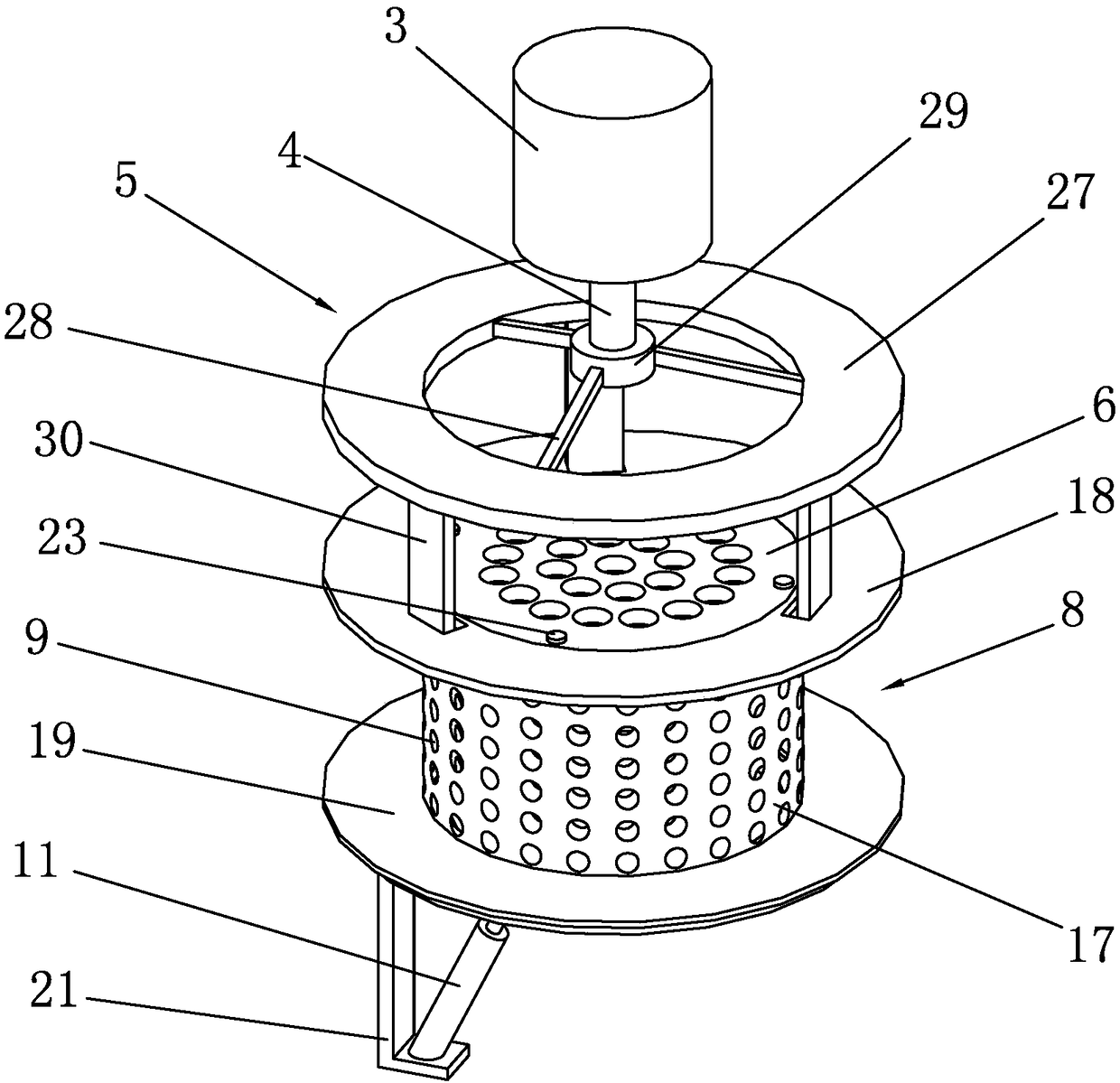

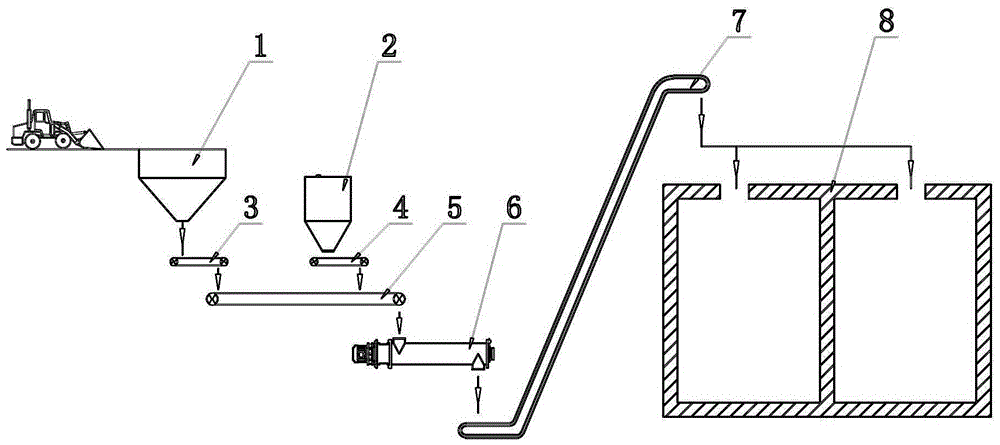

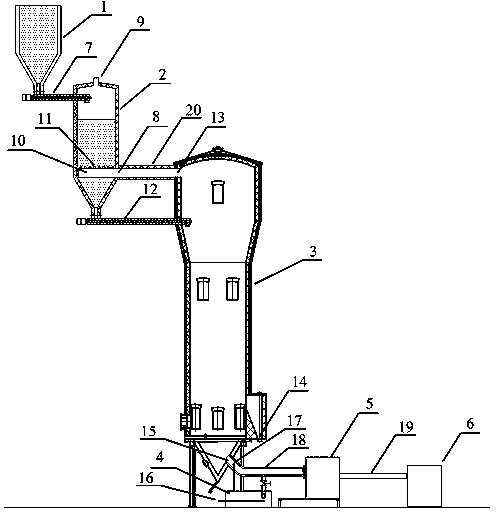

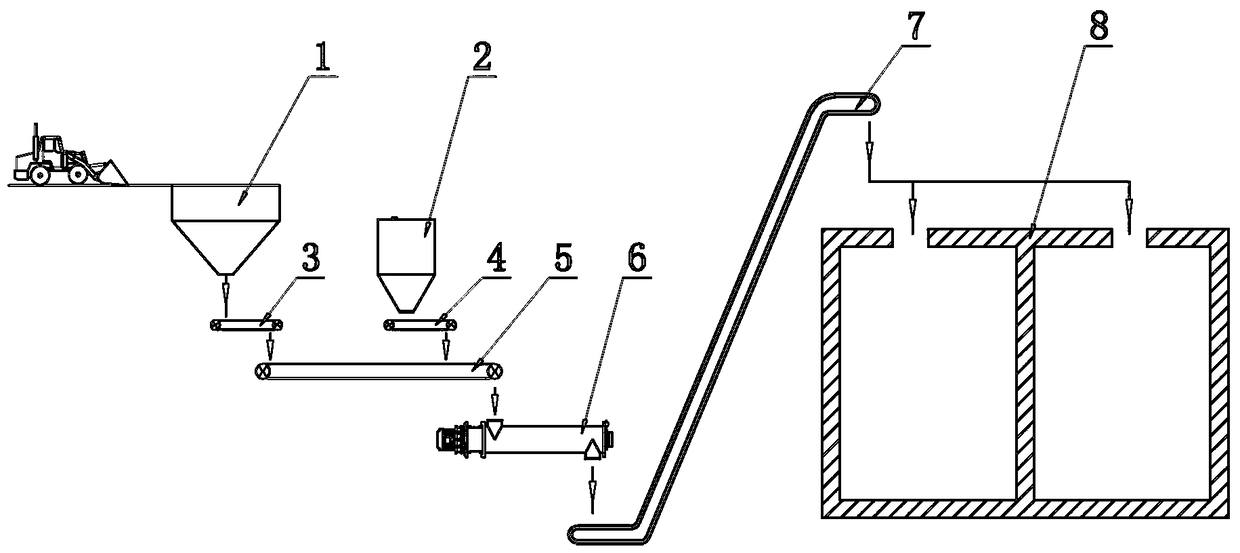

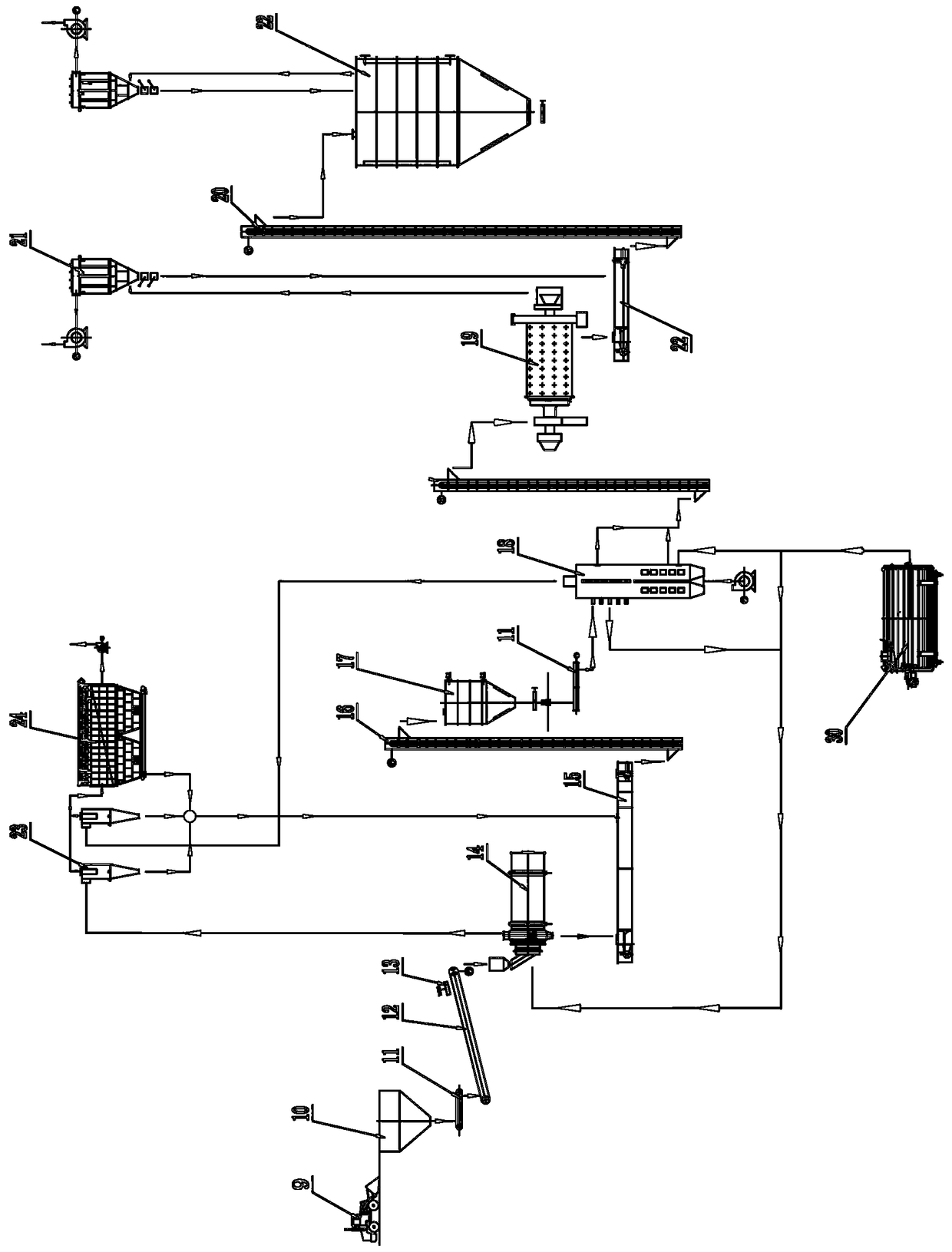

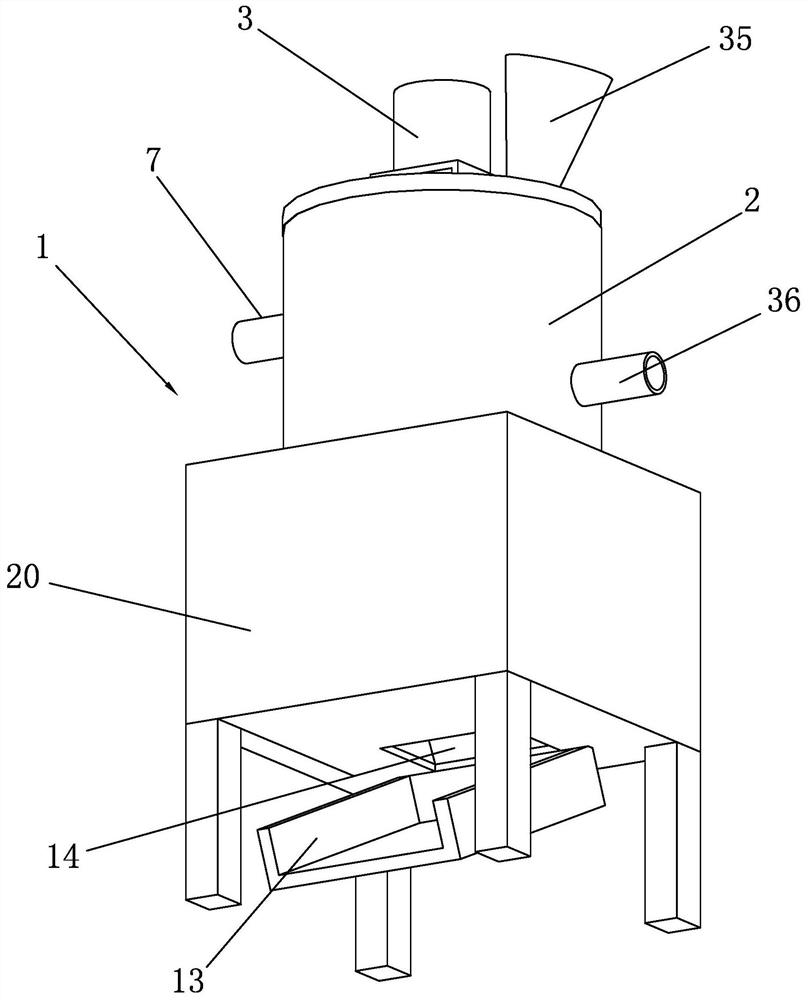

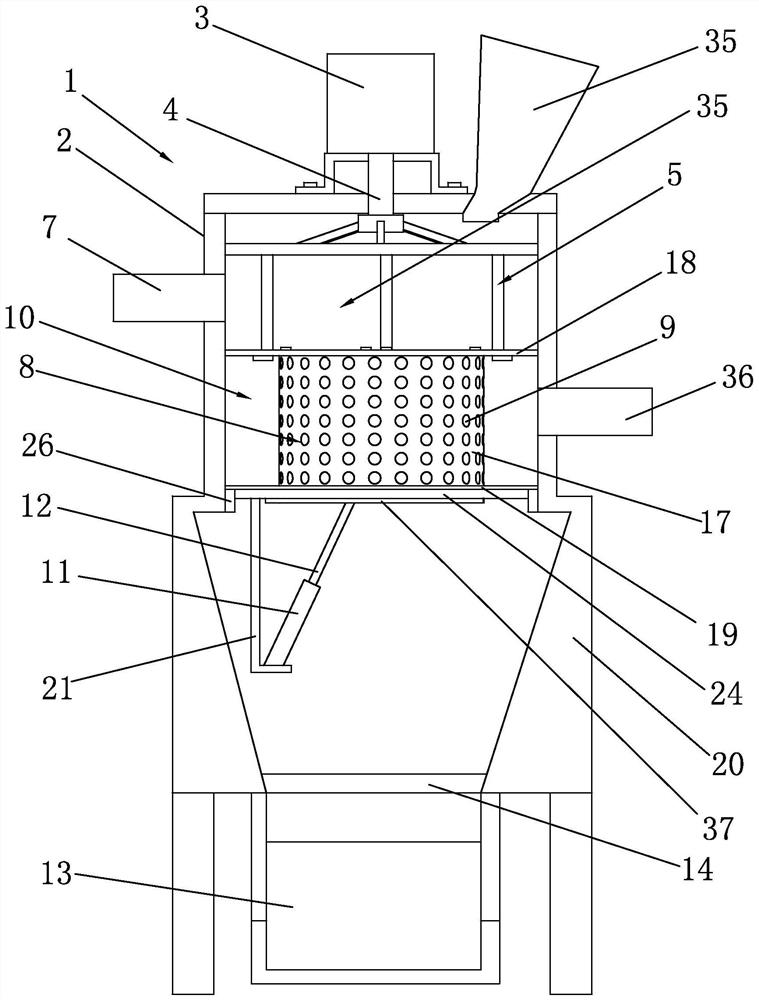

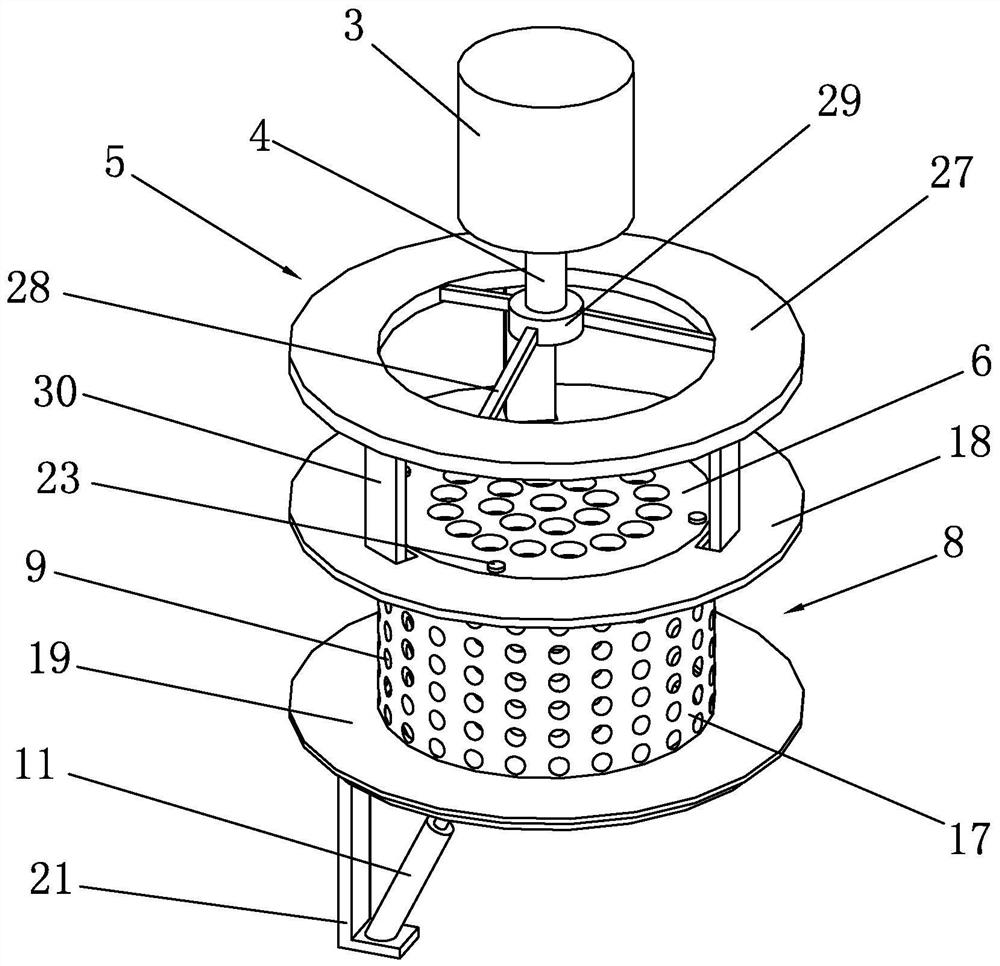

Device for preparing building gypsum from phosphorus gypsum and method using device

The invention relates to a device for preparing building gypsum from phosphorus gypsum and a method using the device and belongs to mineral processing equipment. According to the technical scheme, the device for preparing building gypsum from phosphorus gypsum comprises an ageing device at the front part, a drying device and a baking device in the middle as well as a ball milling device at the rear part, wherein the ageing device comprises a raw material hopper, an additive bin, a mixing device and an ageing bin which are arranged in sequence, conveying mechanisms are arranged below the raw material hopper and the additive bin and extend into a mixing machine, and the mixing machine conveys the mixed mixture into the ageing bin; an iron separator is further arranged at the front part of the baking device, a conveying device I extending to a middle bin is arranged at the discharge end of the baking device, a conveying device II extending to a boiling furnace of the baking device is arranged at the discharge end of the middle bin, a conveying device III extending to a ball milling device is arranged at the discharge end of the boiling furnace, and a conveying device IV extending to a finished product bin is arranged at the discharge end of the ball milling device.

Owner:枣庄盛世机械科技有限公司

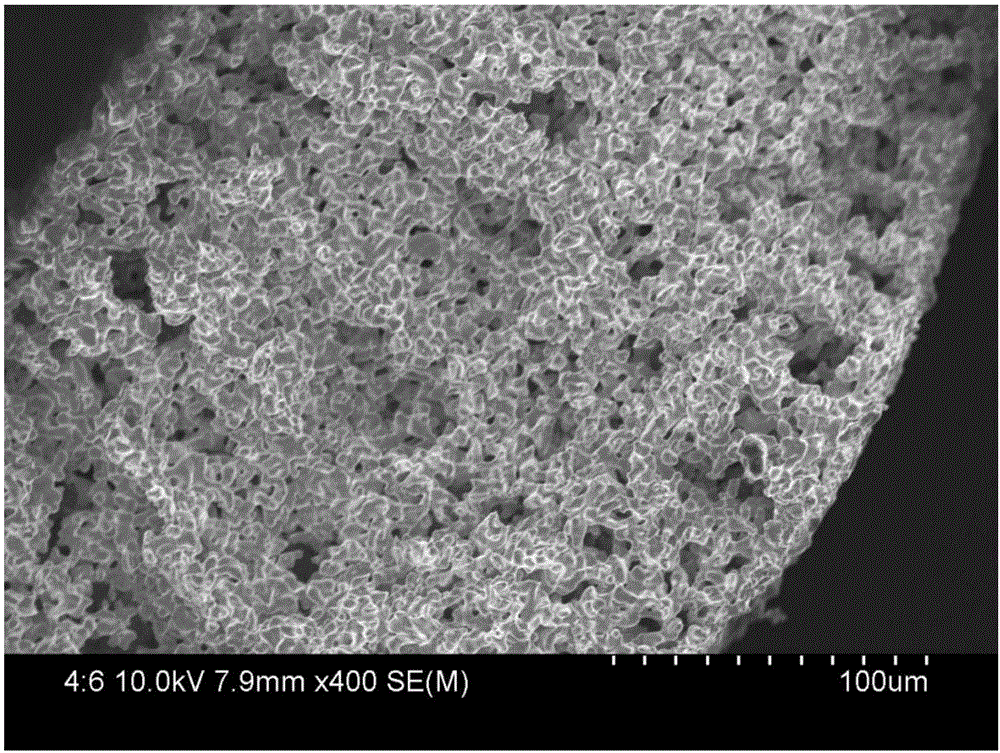

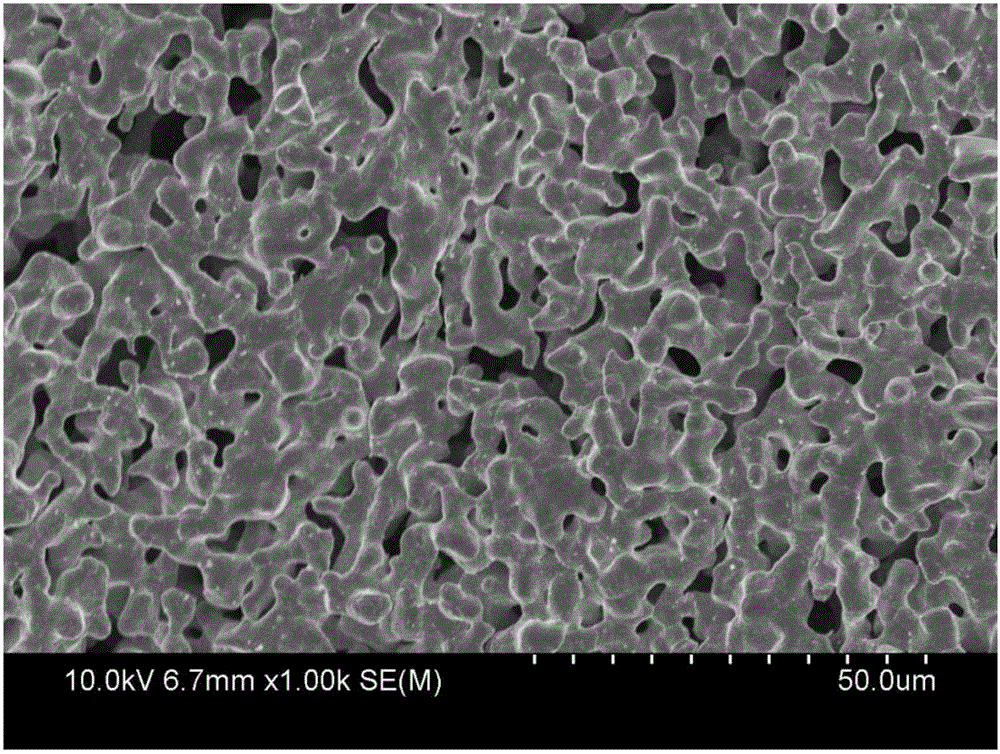

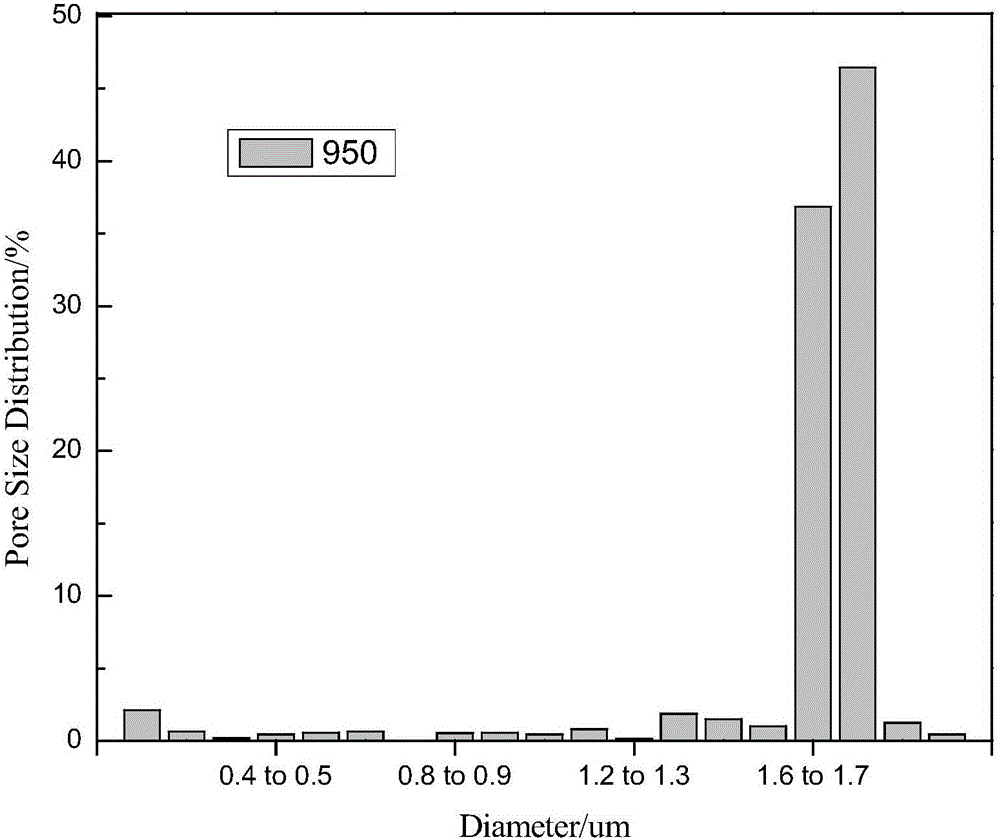

Preparation method of porous nickel hollow fiber membrane and porous nickel hollow fiber membrane prepared by same

The invention discloses a preparation method of porous nickel hollow fiber membrane and a porous nickel hollow fiber membrane prepared by the same. The preparation method comprises the following steps: (1) preparing a membrane casting liquid by evenly mixing the following components together: 35 to 55% of nickel powder with a diameter of 0.5-50 [mu]m, 5 to 10% of binder, 0 to 1% of thickening agent, and the balance being a solvent; (2) preparing a porous nickel hollow fiber membrane precursor by spinning the membrane casting liquid obtained in the step (1) through a dry-wet spinning (NIPS) process; (3) sintering the porous nickel hollow fiber membrane precursor obtained in the step (2), wherein the temperature rising speed is controlled at 1 to 8 DEG C / min in the initial stage of sintering, and the highest temperature of sintering is in a range of 900 to 1100, maintaining the temperature for 0 to 150 minutes after the highest temperature of sintering is reached, and naturally cooling to obtain the porous nickel hollow fiber membrane.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of calcium hydroxide with high porosity

The invention provides a preparation method of calcium hydroxide with the high porosity. The preparation method comprises the following steps: (1) high-temperature calcinations treatment; (2) breakingand screening of calcium oxide stone; (3) digestive reaction; (4) filtering and dewatering treatment; (5) baking and drying; and (6) screening and filtering treatment. The preparation method has thegreatest characteristics that by increasing the temperature of digestion water to be 85-100 DEG C greatly and increasing the material digestion temperature to be 145-155 DEG C, a material is sufficiently expanded under the high-temperature digestion state; and water in pores in powder is quickly evaporated, expanded and gasified, and by serving as a pore-forming agent, the porosity and the pore diameter of the interior of the powder are increased greatly. On the basis of the original high specific surface area, by increasing the pore diameter of the micropores in the powder, the worldwide problems that in the solid-liquid reaction process, liquid is difficult to infiltrate into the powder, and consequently the reaction speed is low, and reacting is not thorough are reduced.

Owner:南京格暠环保科技有限公司

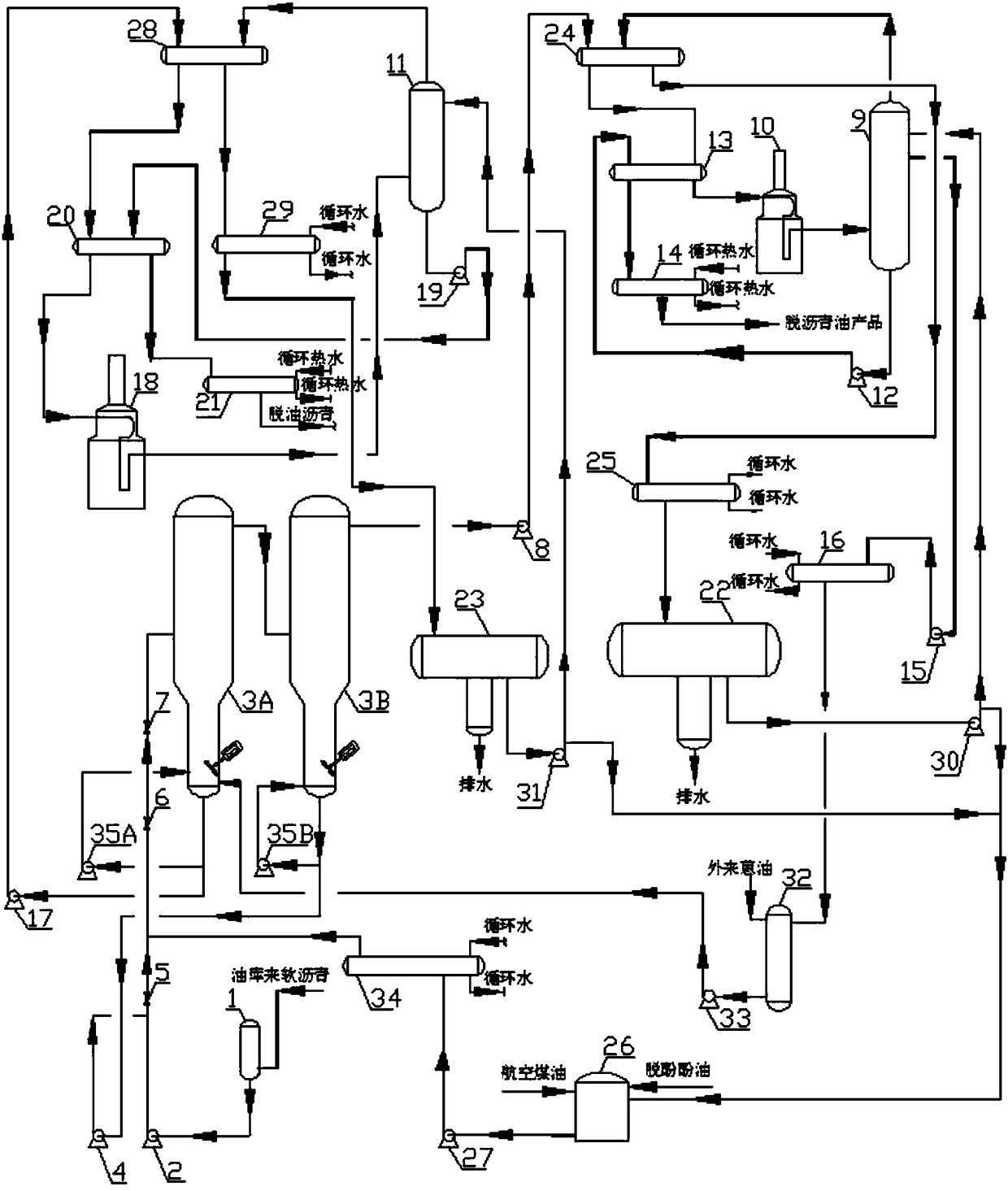

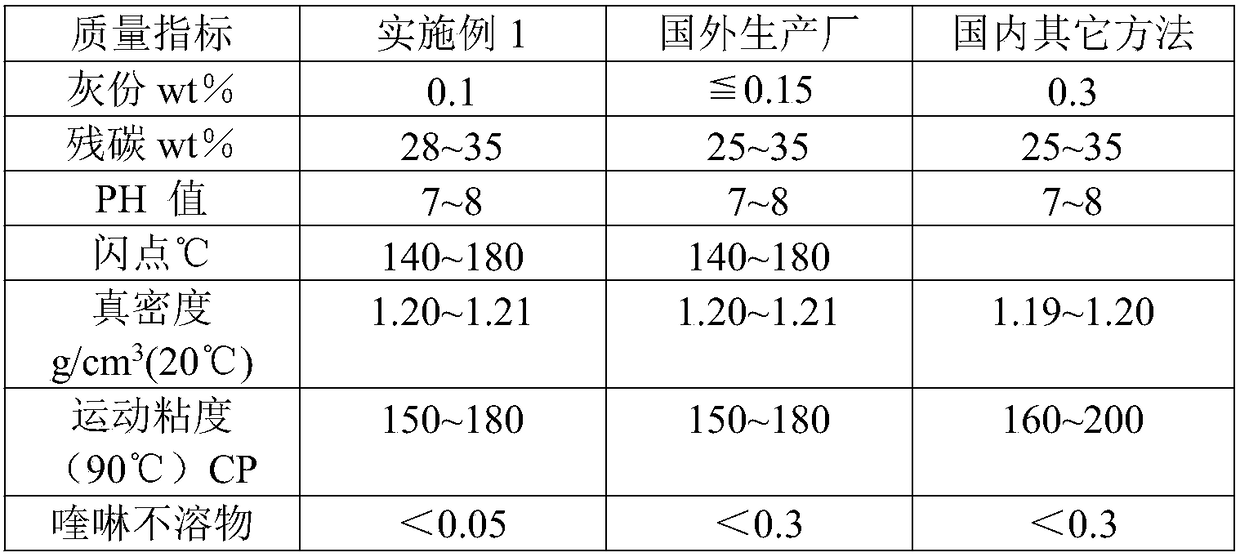

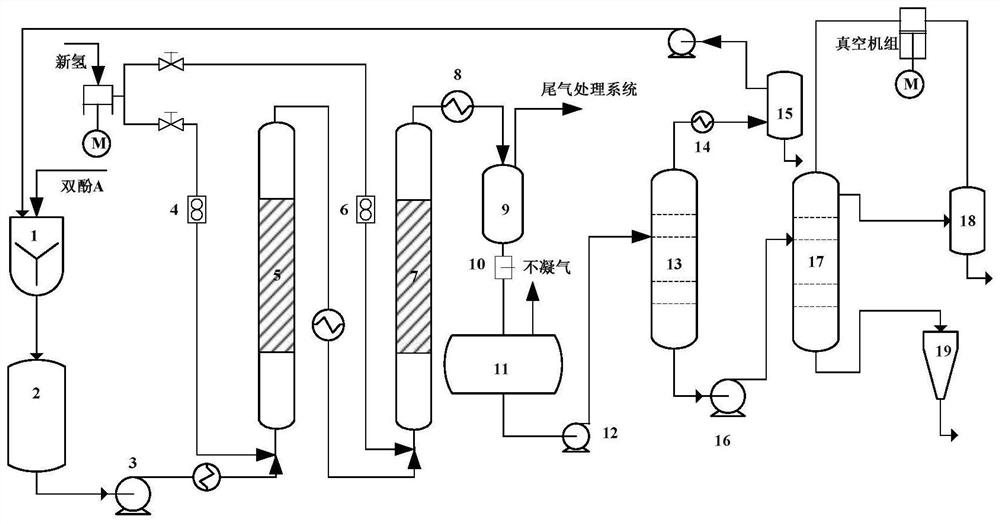

Raw material pretreatment solvent extraction system and method for needle coke industrial production

ActiveCN108395904AReduce contentEasy to operateTreatment with plural serial refining stagesTar working-up by solvent extractionDistillationAliphatic hydrocarbon

The invention provides a raw material pretreatment solvent extraction system and method for needle coke industrial production, and belongs to the field of needle coke production. The extraction systemcomprises a first extracter, a second extracter, a deasphalted oil stripping tower, a deasphalted oil solution heating furnace, a deoiled asphalt stripping tower, a deoiled asphalt solution heating furnace and the like. Needle coke raw materials needing to be pretreated are continuously extracted by a two-furnace two-tower way and two extracters as main devices; an aromatic hydrocarbon and aliphatic hydrocarbon mixed solvent is selected to be continuously extracted together with maltha in the two extracters, the maltha is divided into light phase oil and heavy phase oil by the mixed solvent,and settling separation in the two extracters are conducted by using proportion difference between the light phase and the heavy phase, so that impurities such as quinoline insolubles in maltha are separated from the heavy phase oil; and by using a distillation and stripping principle, the solvents in the light phase oil and the heavy phase oil are recovered and recycled by a one-furnace and one-tower process, high-quality deasphalted oil is obtained in the light phase oil, and deoiled asphalt byproducts are obtained in the heavy phase oil.

Owner:山西宏特煤化工有限公司

Virus and vaccine of porcine reproductive and respiratory syndrome and preparation method of same

ActiveCN101979514AHigh viral titerHigh poison priceViral antigen ingredientsAntiviralsFreeze-dryingCells/microL

The invention discloses a method for preparing virus of porcine reproductive and respiratory syndrome on a large scale. In the method, the virus of the porcine reproductive and respiratory syndrome is prepared in a cell microcarrier suspension culture system by a bioreactor. The method comprises the following steps of: inoculating host cells for preparing the virus to a carrier tank containing culture solution and a microcarrier, and mixing the cells and the microcarrier uniformly to ensure that the cells are attached to the microcarrier; providing sufficient nutrients and appropriate gas environment for the cells under the appropriate culture environment to ensure that the cells are grown until the cells are in an amount which are 10 to 20 times of the inoculation concentration on the microcarrier; preparing virus suspension from the virus of the porcine reproductive and respiratory syndrome by using cell maintenance culture solution to ensure that the suspension is adsorbed to the cells; culturing the virus under the appropriate culture environment; culturing continuously for 2 to 3 days to obtain virus solution; and after the virus solution passes inspection, performing freeze thawing on the virus solution twice at the temperature of -20 DEG C, and inactivating and purifying to prepare an inactivated vaccine of the porcine reproductive and respiratory syndrome or adding a freeze-drying protective agent for freeze drying to prepare a live vaccine of the porcine reproductive and respiratory syndrome. The method has large production scale, high yield of single batch and low production cost.

Owner:PU LIKE BIO ENG

Method for preparing tributyl citrate by using tubular reactor

ActiveCN106674008ASimple equipmentEfficient responseOrganic compound preparationCarboxylic acid esters preparationButanolCitric acid

The invention discloses a method for green and continuous production of tributyl citrate. A tubular reactor (containing an efficient soil catalyst) is used to realize efficient conversion of citric acid and butanol and combined with a continuous impurity removal technology and a continuous rectification technology, continuous production of the product is realized, the purity of the product, namely, tributyl citrate, is higher than or equal to 99.0, and the yield of the main product, namely, tributyl citrate, is higher than 98.0%, and no pollution is caused in the whole process.

Owner:NANJING POLYTECHNIC INSITUTE

Vacuum introduction processing method for weather-resistant FRP products

The invention provides a vacuum infusion machining method for weather-resistant fiberglass reinforced plastics (FRP) products. The method comprises the steps of preparing a mould - applying gel coat - laying at least three layers of fiberglass - laying an isolating membrane with holes - laying and arranging guide pipes - laying a guide net - laying a vacuum bag - vacuum pumping - resin leading-in - demoulding; the laying sequence of the guide pipes and the guide net in the traditional vacuum infusion machining method is changed, and the inside surfaces of the FRP products prepared are free of pipe pressure traces; the gel coat resin prepared is made of raw material constituents which are excellent in performance and able to coordinate with each other, and the gel coat prepared is excellent in weatherability and able to prevent early aging of the FRP products in high temperature, severe cold or other environments; the basic resin in the invention is able to infiltrate the fiberglass properly, and the FRP products prepared finally is high in quality and stability, excellent in weatherability, and applicable for outdoor use.

Owner:CHONGQING HAIQING NEW MATERIAL

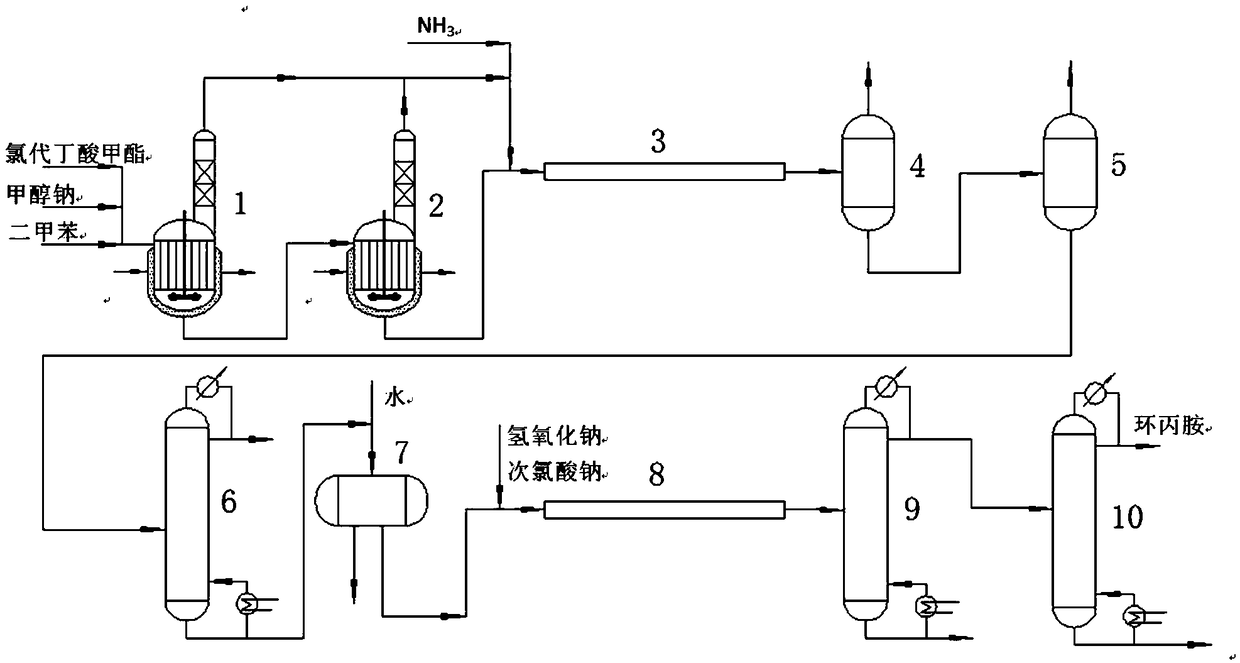

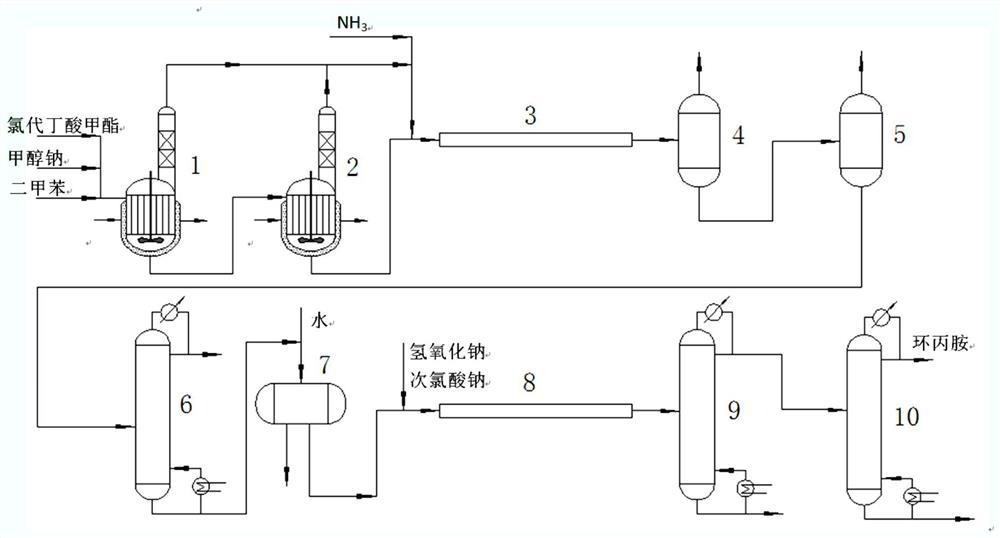

Rolicyprine continuous production system and production method

ActiveCN108129330AHigh yieldIncrease productivityAmino compound purification/separationOrganic compound preparationPhase splitterFirst-order reaction

The invention belongs to the field of chemical production and particularly relates to a rolicyprine continuous production system and a production method. The rolicyprine continuous production system comprises the following production devices connected sequentially: a first-order reaction distillation kettle, a second-odor reaction distillation kettle, an ammonization reactor, a deamination tank, aflash tank, a demethanolization tower, a phase splitter and a degradation reactor. The invention relates to the method for producing rolicyprine by using the rolicyprine continuous production system,and solves the existing problem of intermittent production of the rolicyprine; the mobility and the filterableness of the material are improved in the processes of cyclization, ammoniation, and ammoniation distillation; the degrading process of cyclopropyl carboxamide is improved, meanwhile, the high conversation rate and the high yield of the rolicyprine are guaranteed at the same time, and thecontinuous production of the rolicyprine is realized.

Owner:SHAXING CHEM TAIZHOU CITY

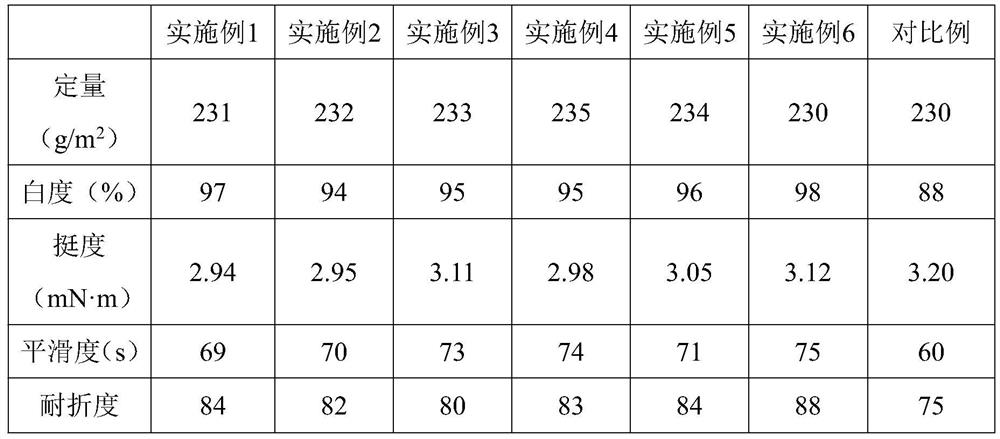

High-whiteness coated ivory board and preparation method thereof

PendingCN113668281AAvoid yellowingGood printability of paperCoatings with pigmentsSpecial paperPolymer scienceWhitening Agents

The invention relates to the field of papermaking, and discloses a high-whiteness coated ivory board and a preparation method thereof. The high-whiteness coated ivory board comprises raw paper and a coating layer covering the surface of the raw paper, wherein the raw paper comprises a surface paper layer, a core paper layer and a bottom paper layer, the coating layer comprises a pre-coating layer, a surface coating layer and a back coating layer, the paper pulp of the raw paper comprises 80-90 parts of hardwood pulp and 10-20 parts of softwood pulp, the paper pulp is formed by bleaching treatment through a biological enzyme method, the coating materials of the pre-coating layer, each of the surface coating layer and the back coating layer comprises a pigment, a coating adhesive and a coating additive, the pigment comprises 85-95 parts of ground calcium carbonate and 5-15 parts of kaolin, and the coating additive comprises a fluorescent whitening agent accounting for 0.05-0.10% of the total weight of the coating materials. The preparation method comprises the steps of paper pulp preparation, net loading, squeezing and water removal, preliminary drying, on-line coating in a machine, drying and subsequent calendaring, reeling, cutting and packaging. The invention provides a method for preparing the high-whiteness coated ivory board by using a biological enzyme method for bleaching and using a small amount of a whitening agent, and the whiteness of the prepared coated ivory board is 94% or above.

Owner:湖北骏马纸业有限公司

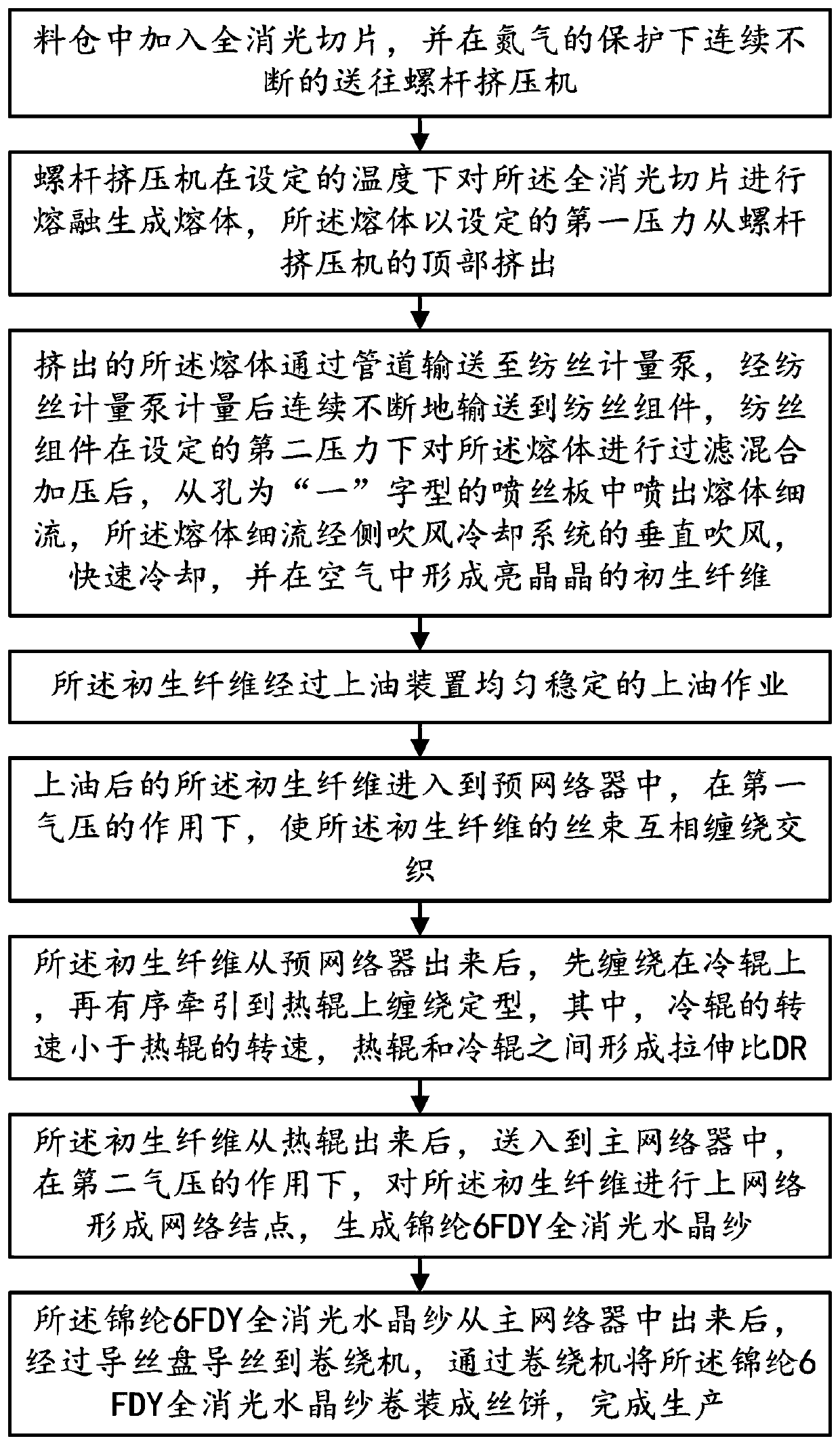

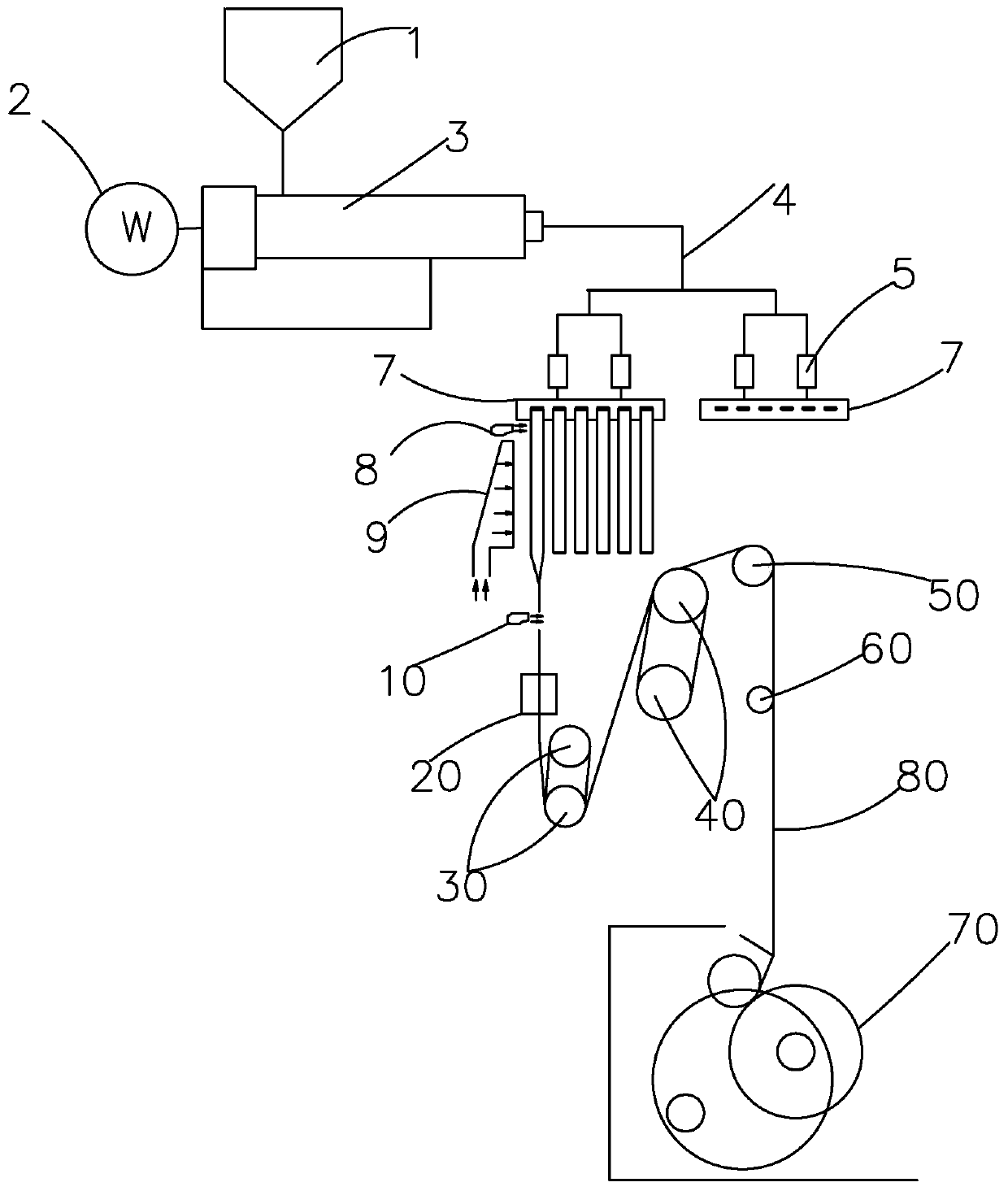

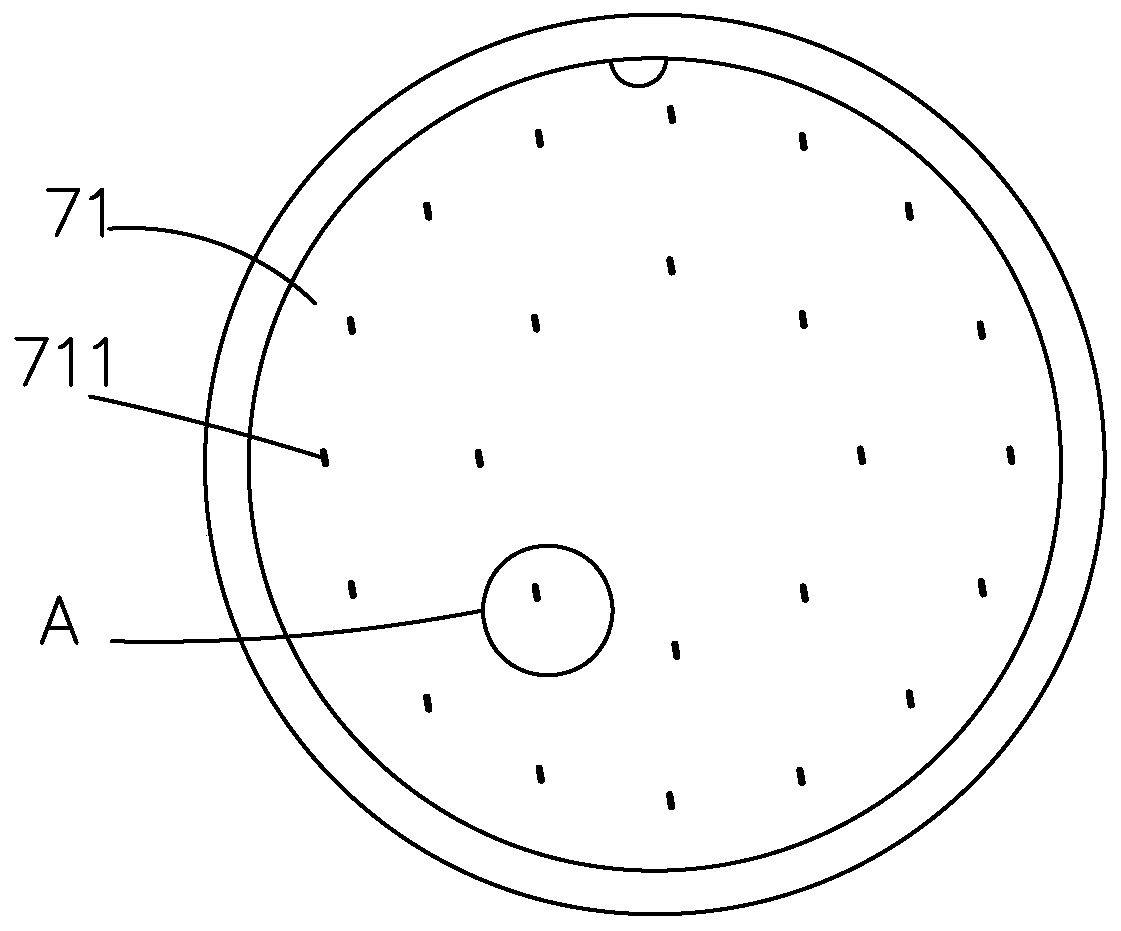

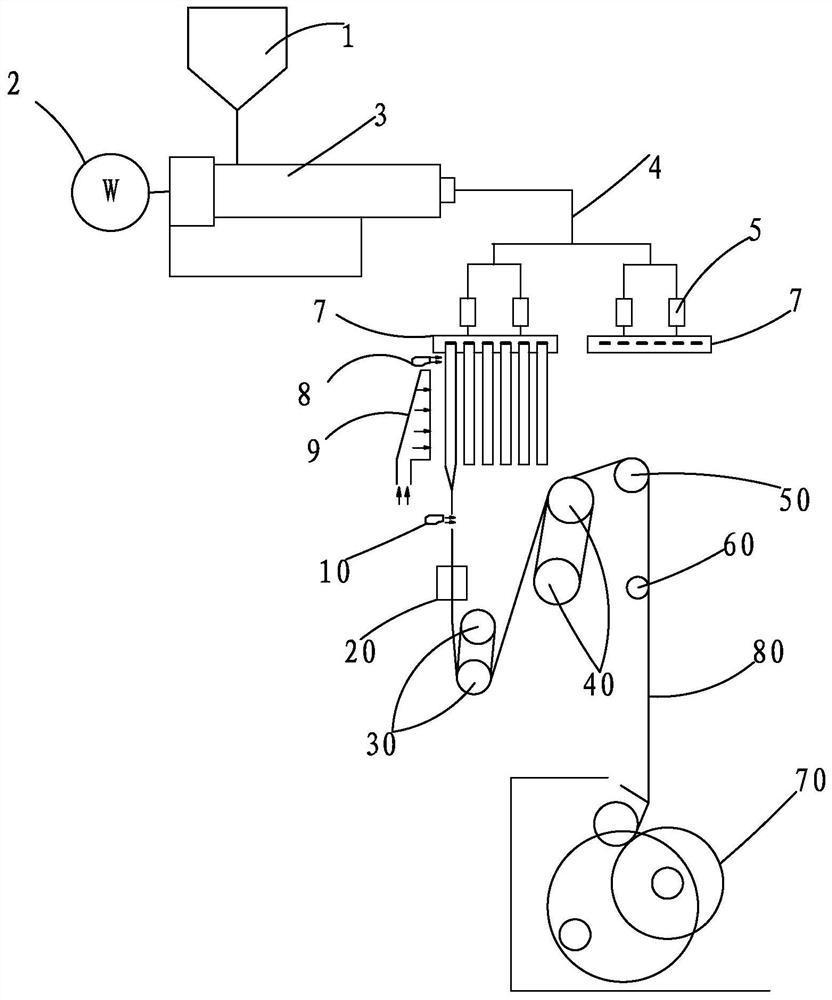

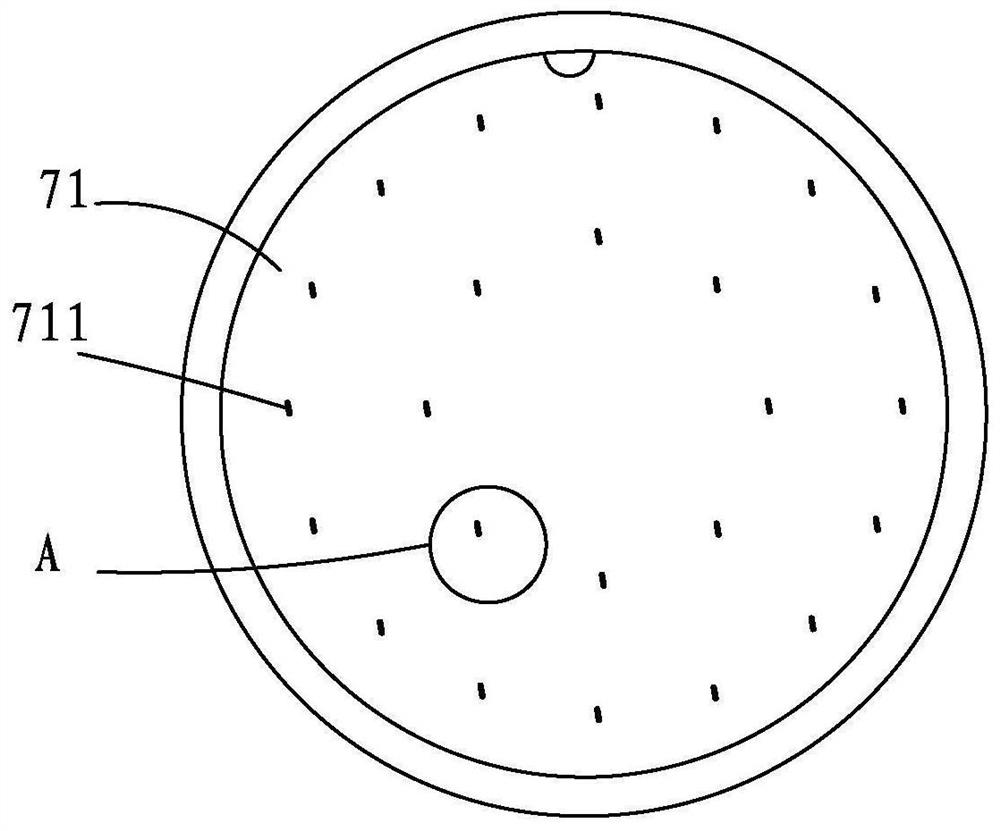

Production method of polyamide 6FDY complete-extinction crystal yarn

ActiveCN111118638AGood colorSpeed up coolingArtificial thread manufacturing machinesFilament/thread formingYarnFiber

The present invention provides a production method of a polyamide 6FDY complete-extinction crystal yarn in the field of textile chemical fibers. The production method comprises the steps of S10, adding a complete-extinction slice into a material bin and conveying to a screw extruder; S20, performing melting at a set temperature, and extruding a melt from the top of the screw extruder at the set first pressure to be conveyed to a metering pump; S30, performing metering and then conveying the melt to a spinning assembly, performing filtering, and mixing pressurizing on the melt at the set secondpressure, and cooling the melt trickles sprayed from a spinneret plate by a cross air blasting cooling system to form nascent fibers; and S40, enabling the nascent fibers to pass through an oiling device, a pre-networking device, a cold and hot roller and a main network device to generate a complete-extinction crystal yarn, and winding the complete-extinction crystal yarn into a yarn cake. The production method has the advantages that the new fibers with smooth feeling, elastic and soft hand feel, stereoscopic feeling, comfort in wearing, fuzzy light spots on the fabric cloth and easiness incoloring are produced, and the production process is simple, the efficiency is high, the product quality is high and stable.

Owner:CHANGLE LIHENG POLYAMIDE TECH +1

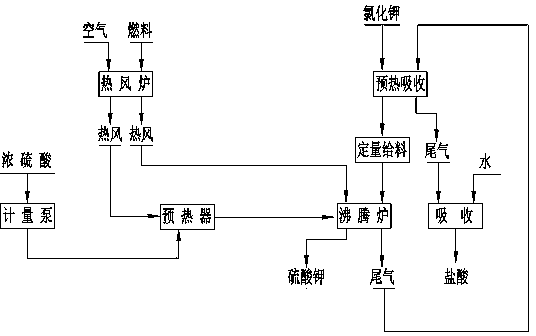

Device and method for producing potassium sulfate by utilizing fluidized bed furnace reactor

InactiveCN104291361AEquipment corrosion is smallReduce maintenanceSulfate/bisulfate preparationEnergy inputHot blastChemistry

The invention provides a device and a method for producing potassium sulfate by utilizing a fluidized bed furnace reactor. The device mainly consists of a potassium chloride feeding device, a potassium chloride preheater, a fluidized bed furnace reactor, a sulfuric acid preheater, a hot blast heater and a fan, wherein the potassium chloride feeding device is connected with the potassium chloride preheater through a potassium chloride conveyor; the potassium chloride preheater is connected with the fluidized bed furnace reactor; the sulfuric acid preheater is connected with the fluidized bed furnace reactor; and the fluidized bed furnace reactor is connected with the hot blast heater and the fan through a pipeline. The device disclosed by the invention is slight in equipment corrosion, large in yield and high and stable in quality, and the energy conservation and consumption reduction aims are achieved.

Owner:LIAOCHENG UNIV

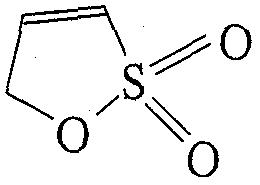

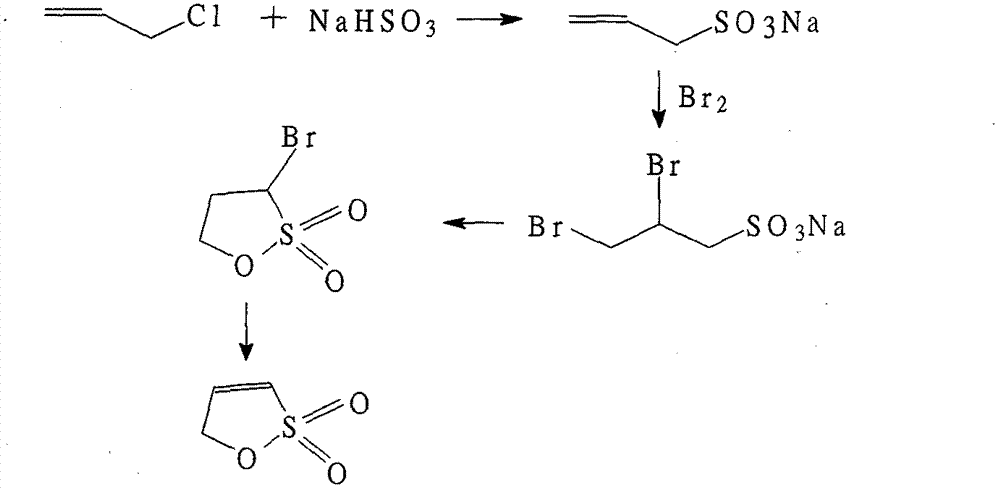

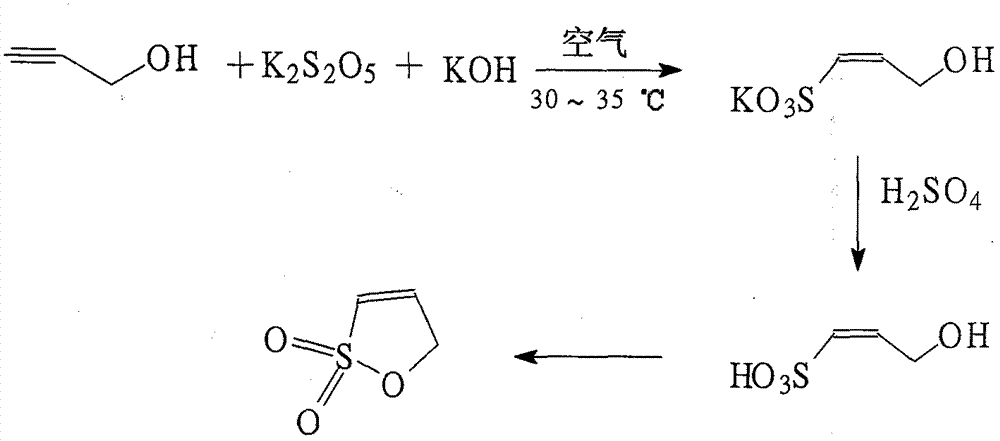

Method for preparing 1-propone-1,3-sultone

The invention relates to a method for preparing 1-propene-3-sultone, and the technical field of preparation of organic materials. The method mainly comprises the processes of addition, acidation and cyclization: a, addition, namely an addition reaction of propargyl ethanol and alkali metal sulphite or hydrosulfite is carried out in an aqueous solution, the molar ratio of the propargyl alcohol to the alkali metal sulphite or the hydrosulfite is 1:1-10, and inorganic acid or organic acid is added to stop reaction after the addition reaction is ended; and b, a product of the addition reaction is separated out, and then the separated product is subjected to cyclization and separation to obtain a 1-propene-3-sultone product. The PST product can be refined. The method overcomes the defect of the prior art, and has the remarkable advantages of unique method, simple manufacturing process, easy operation, mild reaction conditions, cheap and easily-obtained raw materials, higher yield, good selectivity, high and stable quality of products, few three wastes, lower cost, remarkable economic benefit, and the like.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

Device and method for preparing building gypsum from phosphogypsum

The invention relates to a device for preparing building gypsum from phosphorus gypsum and a method using the device and belongs to mineral processing equipment. According to the technical scheme, the device for preparing building gypsum from phosphorus gypsum comprises an ageing device at the front part, a drying device and a baking device in the middle as well as a ball milling device at the rear part, wherein the ageing device comprises a raw material hopper, an additive bin, a mixing device and an ageing bin which are arranged in sequence, conveying mechanisms are arranged below the raw material hopper and the additive bin and extend into a mixing machine, and the mixing machine conveys the mixed mixture into the ageing bin; an iron separator is further arranged at the front part of the baking device, a conveying device I extending to a middle bin is arranged at the discharge end of the baking device, a conveying device II extending to a boiling furnace of the baking device is arranged at the discharge end of the middle bin, a conveying device III extending to a ball milling device is arranged at the discharge end of the boiling furnace, and a conveying device IV extending to a finished product bin is arranged at the discharge end of the ball milling device.

Owner:枣庄盛世机械科技有限公司

Preparation method of high fructose corn syrup prepared through plant starch hydrolysis and isomerization

InactiveCN108893510AEnergy savingLow costFructose productionFermentationAlant starchActivated carbon

The invention discloses a preparation method of high fructose corn syrup prepared through plant starch hydrolysis and isomerization. The preparation method includes the steps of S1, plant starch hydrolysis; S2, saccharification; S3, isomerization; S4 evaporation and concentration. The preparation method has the advantages that a pre-concentration procedure is omitted, energy is saved, and cost issaved; an organic membrane is used for filtering, and a decoloring effect is increased by the filtering coordinated with two subsequent activated-carbon decoloring; reaction conditions are controlledstrictly, and the prepared high fructose corn syrup is good in color and taste and high and stable in quality.

Owner:安徽启慧信息科技有限公司

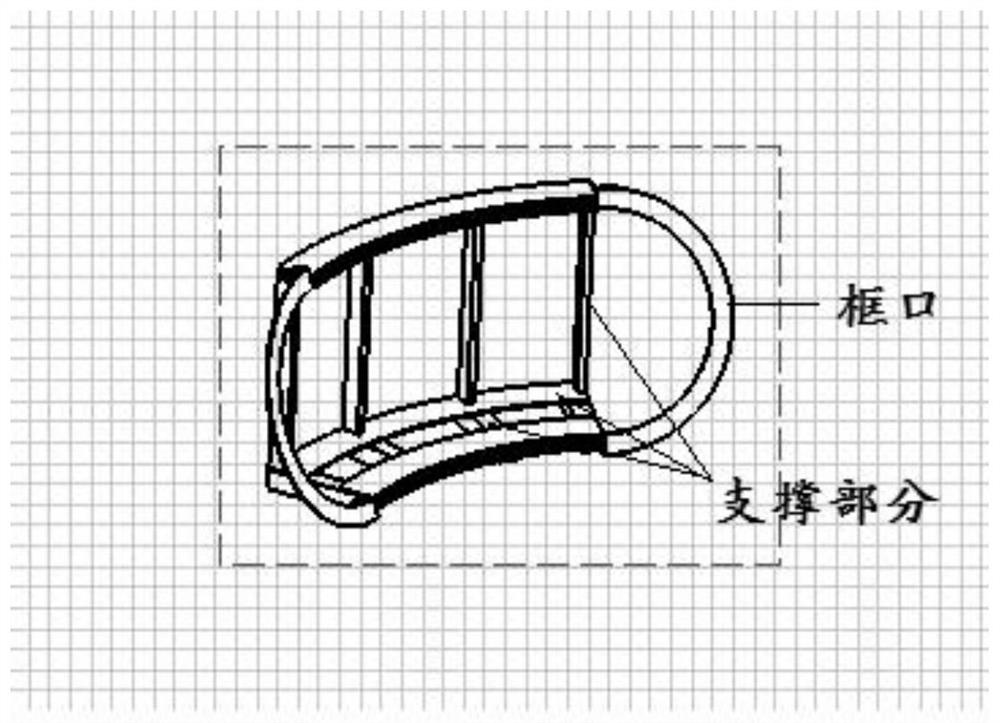

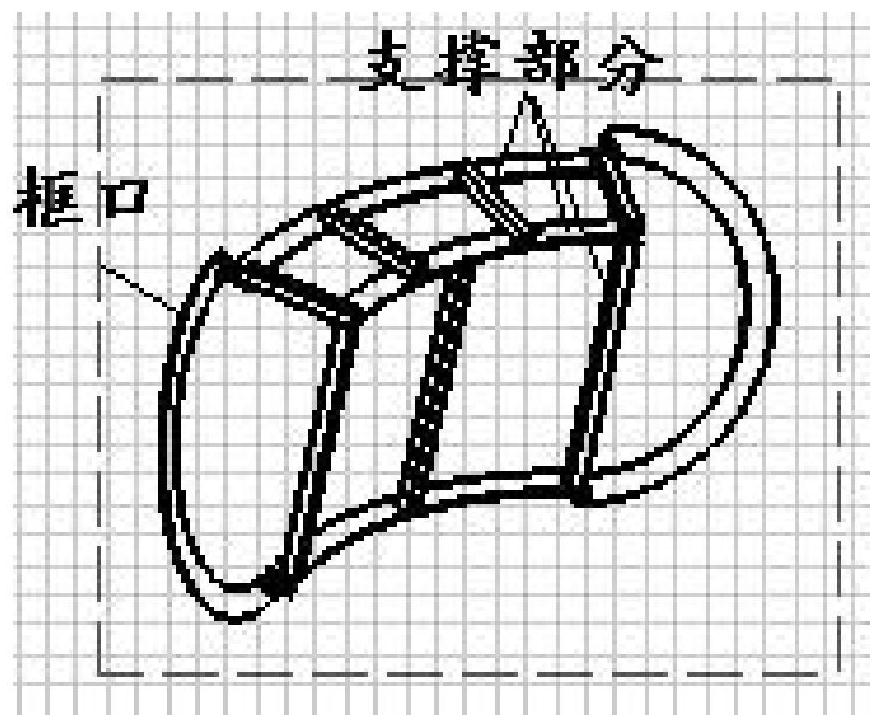

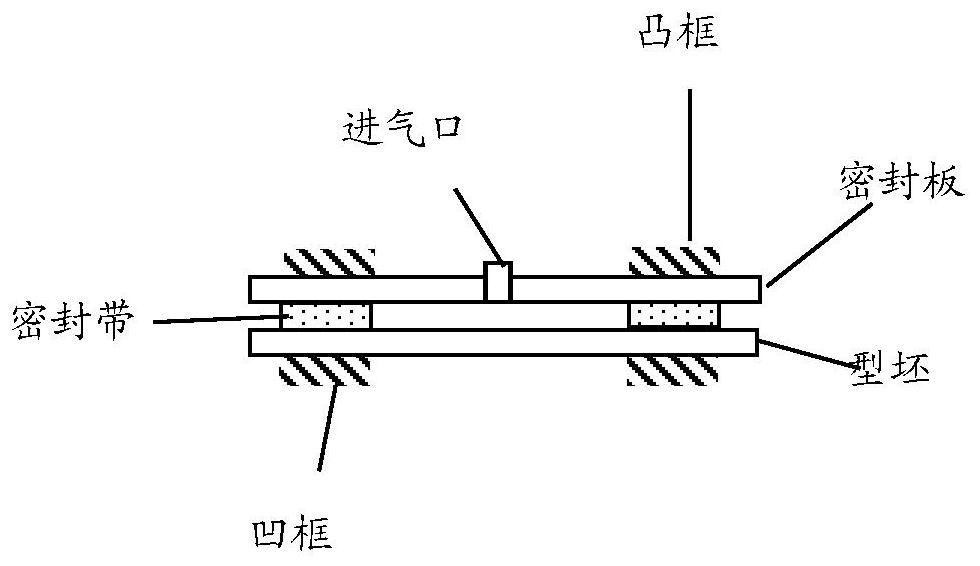

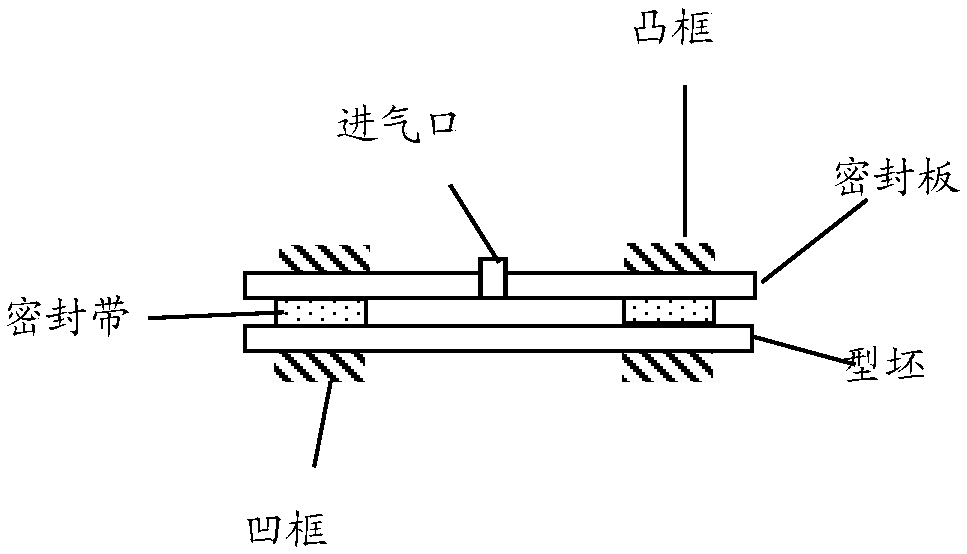

A kind of preparation method of quadric mirror

ActiveCN109624265BReduce investmentReduce manufacturing costOptical articlesBlow moldingUltrasonic welding

The invention belongs to the technical field of curved surface mirrors. The preparation method provided by the present invention directly uses the metal-coated thermoplastic non-crystalline resin plate as a raw material, and obtains a parison by cutting and ultrasonic welding, and then obtains a quadratic surface by controlling the temperature of the blow molding process at one time. Reflector. This method reduces the investment in basic equipment, production costs and technical risks, and the operation process is simple, which significantly improves the yield in the later stage, and the product quality is high and stable; at the same time, the method has good surface consistency, no need for splicing, and the finished product is light in weight. It is convenient; the size and specifications can be changed flexibly, and those skilled in the art can make the molding control frame according to the needs. The process has strong adaptability, and the obtained product has a clean appearance and can be used directly.

Owner:郭远芳

Preparation method of quadric reflector

ActiveCN109624265AReduce investmentReduce manufacturing costOptical articlesBlow moldingUltrasonic welding

The invention belongs to the technical field of curved mirrors. In a preparation method, a thermoplastic non-crystalline resin sheet plated with a metal film is directly adopted as a raw material, a parison is obtained by cutting and ultrasonic welding, and then a quadric reflector is obtained by one-time molding by controlling the temperature of the blow molding process. By means of the method, the basic equipment input, the production cost and the technical risk are reduced, the operation process is simple, the later-period finished product rate is significantly improved, and the product quality is high and stable; and meanwhile, the surface consistency is good, splicing is not needed, the finished product is light in weight and convenient to use, size specification changing is flexible,the person skilled in the art can make a molding control frame according to the needs, the process adaptability is strong, and the obtained product has a neat appearance and can be directly used.

Owner:郭远芳

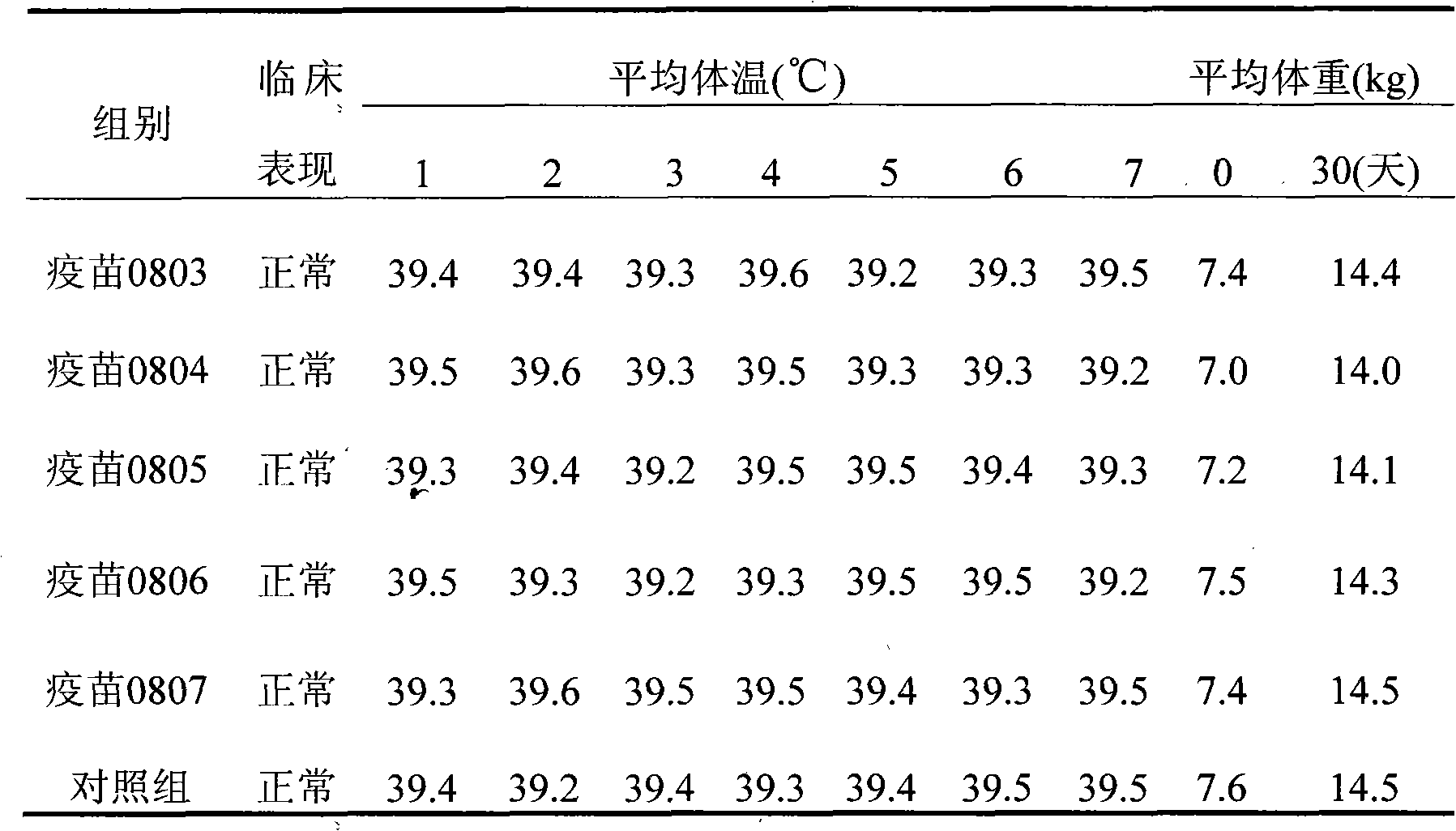

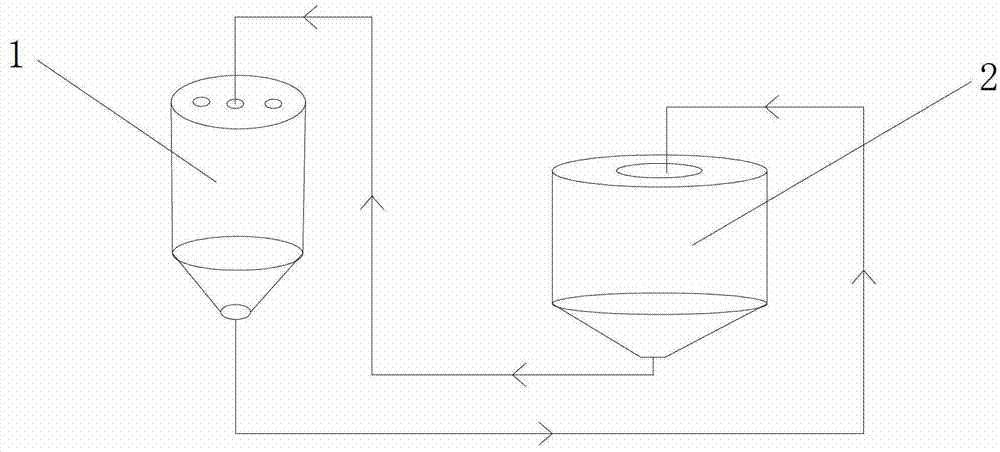

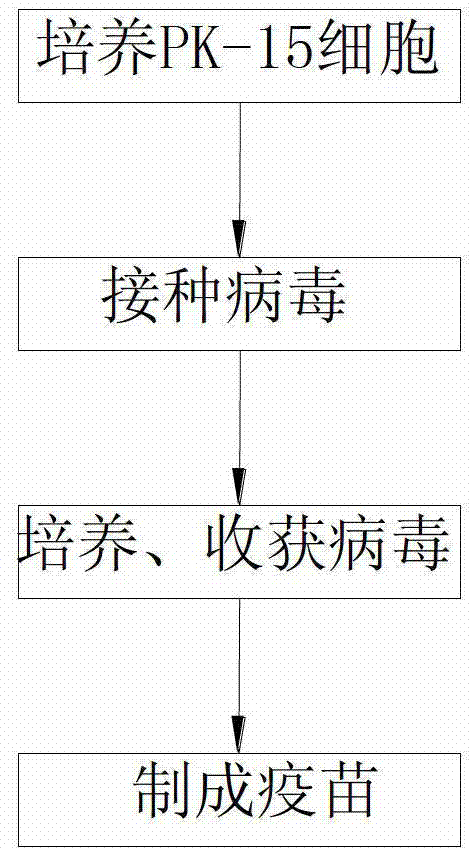

A kind of method utilizing bioreactor to prepare porcine circovirus type 2 inactivated vaccine

ActiveCN103100082BSave production landImprove securityViral antigen ingredientsMicroorganism based processesSide effectCircovirus

The invention relates to a method for preparing porcine circovirus type 2 inactivated vaccine by utilizing a bioreactor, wherein the bioreactor is a riptide type bioreactor; a circulatory system is composed of a perfusion bag and a riptide bag; a cell culture bag is built in the perfusion bag; a paper carrier is in the cell culture bag; and the method comprises the following steps of: culturing PK-15 cells; inoculating porcine circovirus type 2; culturing the porcine circovirus type 2, measuring sugar consumption by taking a virus maintenance solution, and obtaining a virus solution when the sugar consumption is decreased; and preparing the porcine circovirus type 2 inactivated vaccine. The method for preparing the porcine circovirus type 2 inactivated vaccine by utilizing the riptide type bioreactor disclosed by the invention is small in production site, low in labour intensity, relatively lower in production cost, simple in operation, low in inter-batch difference, and high and steady in product quality; full-automatic micro-computer control can be achieved; and the prepared porcine circovirus type 2 inactivated vaccine is good in safety, high in immune efficacy and low in side effect and has the better immune protective effect on virulent attack of porcine circovirus type 2.

Owner:兆丰华生物科技(南京)有限公司 +1

Production process of a new type of nylon 6 with fdy flat cross-section

ActiveCN109440206BFeel softRich in three-dimensionalityMonocomponent copolyamides artificial filamentMelt spinning methodsWinding machineFiber

The present invention provides a kind of production technology of the polyamide fiber 6 of a kind of novel FDY matting flat section, step S1, add full matting slice in the silo; Step S2, slice enter screw extruder, extrude from the top of screw extruder; Step S3. After the melt is metered by the spinning metering pump, filtered, mixed and pressurized by the spinning assembly, a thin stream of the melt is sprayed from the spinneret hole, and then cooled and solidified to form; step S4, the formed primary fiber is processed Oiling operation; step S5, the primary fiber after oiling enters the pre-netting device, and under the action of a certain low air pressure, the tows are intertwined with each other; step S6, the primary fiber is first wound on the cold roll and then pulled in an orderly manner Winding and shaping on the hot roller; step S7, the fiber filaments are sent into the main network device, and the network is carried out; step S8, then winder is wound into a silk cake; the production process of the present invention is simple and efficient. High, high and stable product quality, can effectively meet the needs of the market, and has broad application prospects.

Owner:CHANGLE LIHENG POLYAMIDE TECH +1

Continuous cotton pulp washing and bleaching process

ActiveCN102561093BRealize remote centralized automatic controlEasy to realize remote centralized automatic controlWashing/displacing pulp-treating liquorsPulp bleachingWater savingPulp and paper industry

The invention belongs to the cotton pulp field and particularly provides a water-saving continuous cotton pulp washing and bleaching process, wherein a redesigned drum-type vacuum washer is used to replace the frequently-used horizontal belt washer for cotton pulp dreg bleaching. A countercurrent washing method is used for washing the cotton pulp, not only is water saved, but also the washing effect is good, the labor intensity is reduced, the control accuracy is improved, continuous production is achieved, and the product quality is stable.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

A kind of tubular reactor prepares tributyl citrate method

ActiveCN106674008BHigh degree of automationEasy to operateOrganic compound preparationCarboxylic acid esters preparationTributyl citrateImpurity

The invention discloses a method for green and continuous production of tributyl citrate. A tubular reactor (containing an efficient soil catalyst) is used to realize efficient conversion of citric acid and butanol and combined with a continuous impurity removal technology and a continuous rectification technology, continuous production of the product is realized, the purity of the product, namely, tributyl citrate, is higher than or equal to 99.0, and the yield of the main product, namely, tributyl citrate, is higher than 98.0%, and no pollution is caused in the whole process.

Owner:NANJING POLYTECHNIC INSITUTE

Water-soluble ginkgo leaf extract and preparation technology thereof

ActiveCN102293793BImprove processing stabilityHigh yieldNervous disorderGinkgophyta medical ingredientsBiotechnologyGinkgo Biloba Leaf Extract

The invention relates to a water-soluble ginkgo leaf extract and its preparation technology, The method of the invention comprises: taking common ginkgo biloba as a raw material, mixing with acetone and extracting, concentrating, diluting by adding water, cryoprecipitating, filtering, performing a gradient elution to a filtrate through macroporous adsorption resin, carrying out an alcohol precipitation by ethanol with high purity, water extraction and cryoprecipitating, concentrating, drying to obtain the water-soluble ginkgo leaf extract, wherein the content of total flavonol glycoside is greater than or equal to 27%; the content of lactone content is 9%-12%, wherein the content of Terpene Lactones A is greater than or equal to 2.1%, the content of Terpene Lactones B is greater than or equal to 0.9%, the content of Terpene Lactones C is greater than or equal to 1.2%, and the lactone ratio of GA:GB:GC is close to 7:3:4; the water-solubility is greater than and equal to 10%; the ginkgolic acid is less than and equal to 1ppm, which can be taken as a raw material used for injection. The invention has the advantages of simple production technology, high and stable product quality, high finished product yield, low cost and good economic benefit.

Owner:ZHEJIANG CONBA PHARMA

A kind of preparation technology of highly active anticoagulation calcium hydroxide

ActiveCN108911535BHigh purityQuality improvementSievingGas current separationCalcium hydroxideEconomic benefits

The invention discloses a preparation process of high-activity anti-condensation calcium hydroxide. The preparation process comprises the following steps: (1) high-temperature calcination treatment; (2) crushing screening of calcium oxide stones; (3) digestion reaction; (4) filtration and dewatering treatment; (5) baking drying; (6) screening and filtration treatment. The invention provides a technical scheme of the preparation process of the high-activity anti-condensation calcium hydroxide. An integrated process production process is automatically controlled, the labor strength of workers islow, the operation security performance is also improved, and technical risks are avoided; moreover, a calcium hydroxide product prepared by adopting the preparation process has the advantages of high quality and stability, energy consumption loss during production is low, the yield of the product is high, the purity is high, the production cost is effectively reduced, and the economic benefit isimproved.

Owner:叶萍

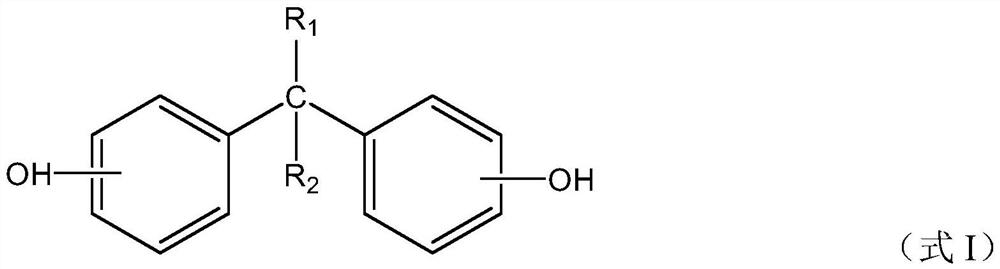

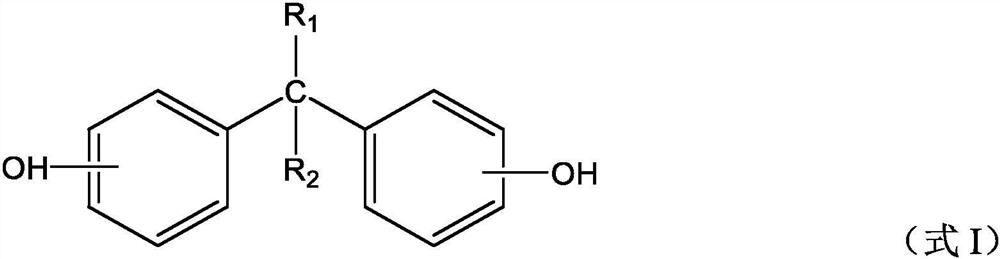

Hydrogenation catalyst, preparation method and application thereof, and hydrogenation reaction method

ActiveCN114643060ALow costImprove low temperature reactivityPreparation by hydrogenationHeterogenous catalyst chemical elementsPtru catalystHydrogenation reaction

The invention discloses a hydrogenation catalyst as well as a preparation method and application thereof, and further discloses a hydrogenation reaction method adopting the hydrogenation catalyst. The hydrogenation catalyst contains a binder and active components, the active components contain nickel and VIB family metal elements, and the binder contains zirconium oxide and aluminum oxide. The catalyst provided by the invention takes nickel as a main active component and is low in cost. Moreover, the catalyst according to the present invention shows improved catalytic activity in the hydrogenation reaction of phenolic compounds, especially improved low-temperature reaction activity. The catalyst disclosed by the invention is suitable for a continuous production process, so that continuous preparation of a hydrogenated bisphenol A product can be realized, and the product quality is high and stable.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

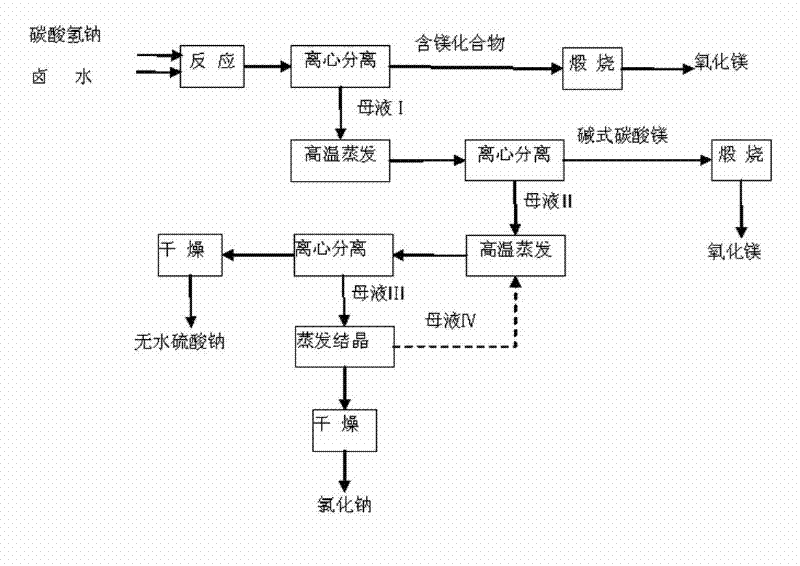

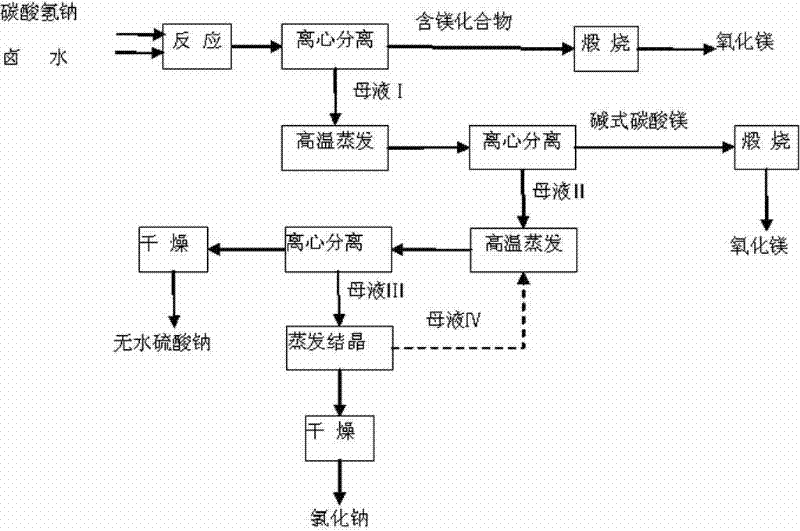

Novel process for producing high-purify magnesium oxide from salt lake brine

InactiveCN102060313BEasy to operateProduct quality is high and stableAlkali metal chloridesMagnesiaSodium bicarbonateCarbonate

The invention discloses a novel process for producing high-purify magnesium oxide from salt lake brine, belongs to the technical field of comprehensive utilization of brine and aims to provide a process for coproducing high-purify magnesium oxide, sodium sulfate and sodium chloride by taking natural salt lake brine and sodium hydrogen carbonate as raw materials. The process comprises the following steps of: blending according to an equivalence ratio of magnesian ions to bicarbonate ions, being (1:2.02)-(1:2.05); separating after reaction to obtain intermediate products, i.e. basic magnesium carbonate and mother liquid I; washing the basic magnesium carbonate with deionized water; calcining the washed basic magnesium carbonate to obtain the high-purify magnesium oxide; evaporating and concentrating the mother liquid I, and then centrifugally separating to obtain the basic magnesium carbonate and mother liquid II; evaporating and concentrating the mother liquid II, and then centrifugingto obtain anhydrous sodium sulfate and mother liquid III; and cooling and crystallizing the mother liquid III to obtain sodium chloride and mother liquid IV. The process has the advantages of realization of comprehensive utilization of brine, simplicity of operation in a reaction process, easiness for industrialized mass production, high magnesium conversion ratio, good product quality, no three-waste emission in the reaction process and favorable environment and societal benefits.

Owner:NAFINE CHEMICAL INDUSTRY GROUP CO LTD

A kind of cyclopropylamine continuous production system and production method

ActiveCN108129330BHigh yieldIncrease productivityAmino compound purification/separationOrganic compound preparationReactive distillationPropylamine

The invention belongs to the field of chemical production, and in particular relates to a continuous production system and production method of cyclopropylamine. The continuous production system of cyclopropylamine comprises the following production devices connected in sequence: a primary reaction still, a secondary reaction still, an ammoniation reactor, a deammonization tank, a flash tank, a methanol removal tower, a phase separator and degradation reactor. The invention relates to a method for producing cyclopropylamine by using the cyclopropylamine continuous production system, which solves the problem of intermittent production of cyclopropylamine in the prior art; improves the fluidity and filterability of materials in the processes of cyclization, ammoniation and ammoniation distillation ; Improve the cyclopropyl formamide degradation process, while ensuring high conversion rate and high cyclopropylamine yield to achieve, to achieve continuous production of cyclopropylamine.

Owner:SHAXING CHEM TAIZHOU CITY

Manufacturing method for ceramic mold casting

InactiveCN112264582AImprove surface accuracyLow costFoundry mouldsFoundry coresElectrolysed waterCeramic mold casting

The invention discloses a manufacturing method of ceramic mold casting, which comprises the following steps of refractory material selecting, adhesive selecting, electrolyzed water preparing, ceramicslurry preparing, ceramic slurry pouring, drawing, torch firing, and roasting, wherein a ventilating agent and a coagulation accelerator are added during preparation of the ceramic slurry, the gelatinization time after ceramic slurry pouring can be adjusted through the addition amount of a coagulation accelerator, the gelatinization time for a small piece can be controlled to be 4-6 seconds, the gelatinization time for medium and large pieces can be controlled to be 8-15 seconds, when the drawing time is about two times of the gelatinization time, the roasting temperature is 870-950 DEG C after gelatinizing is conducted for 5-15 minutes, roasting lasts for 1-3 hours, and therefore cracks are prevented from being generated. Products machined through the method are high in surface precision,low in cost, and high and stable in quality.

Owner:乐清市和瑞恒模具科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com