Preparation method of porous nickel hollow fiber membrane and porous nickel hollow fiber membrane prepared by same

A technology of fiber membrane and porous nickel, which is applied in the field of hollow fiber membrane and its preparation process, can solve problems such as differences in process parameters and sintering process parameters, and achieve the effects of high product quality, light weight and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] A kind of preparation method of porous nickel hollow fiber membrane is characterized in that described method comprises the following steps:

[0029] 1) Configure casting solution

[0030] After mixing all the components in the formulation of the casting solution, heat it in a water bath to 70° C. and stir until they are evenly mixed to obtain the casting solution.

[0031] 2) Preparation of porous nickel hollow fiber membrane precursor

[0032] The casting solution obtained in the above step 1) is spun by a dry-wet method (NIPS) to obtain a porous nickel hollow fiber membrane precursor; Soak in pure water until the solvent is fully separated out, the soaking time is 24 hours, and dry the soaked primary fiber at room temperature to obtain a porous nickel hollow fiber membrane precursor.

[0033] 3) Sintering

[0034] The porous nickel hollow fiber membrane precursor obtained in step 2) is sintered, and the heating rate during sintering is V°C / min;

[0035] When the ...

Embodiment 1~6

[0045] The formula of embodiment 1~6 sees the following table (all solvents all adopt NMP, thickener all adopts PVP, and binding agent all adopts PAN)

[0046]

[0047] Step 3) of all embodiments 1 to 6) Concrete sintering process is as follows

[0048]

[0049]

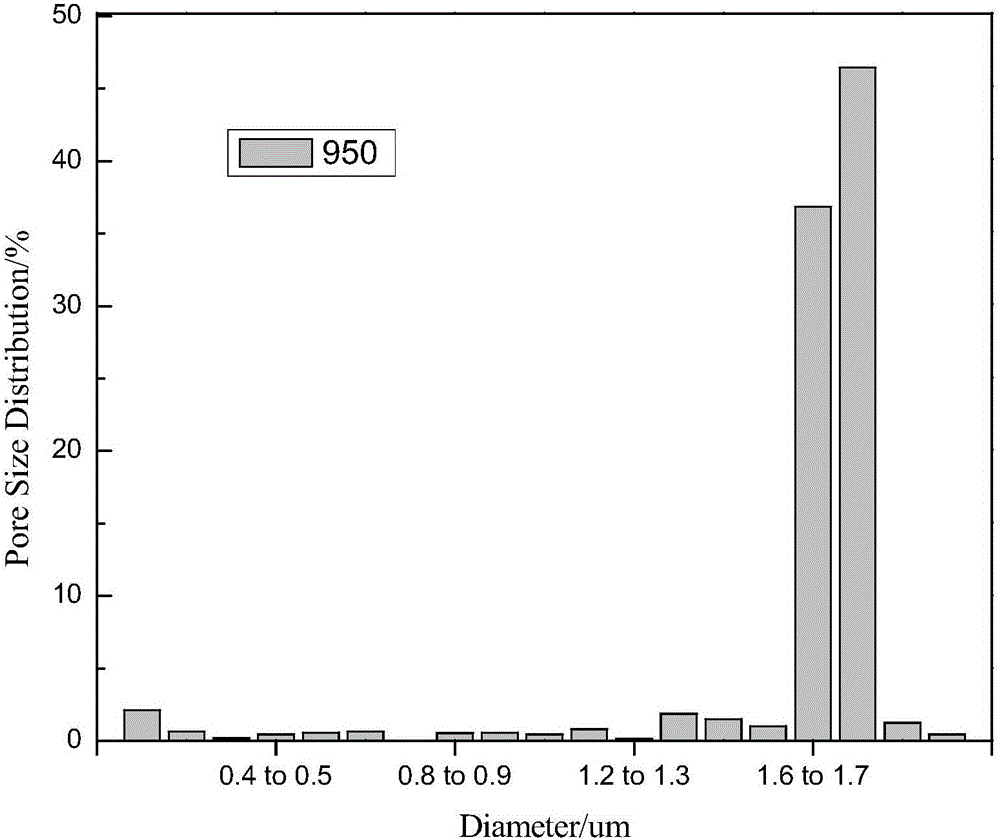

[0050] Note: during the sintering process of Examples 1 and 6, the sintering temperature reaches T 1 The same sintering atmosphere is used before and after, and when T 1The heating rate before was 3°C / min, and then the heating rate was 5°C / min. Aperture refers to 95% aperture distribution range in this table, and aperture distribution detection shows that the average maximum aperture of the porous nickel fiber membrane obtained in embodiment 1-6 does not exceed the upper limit of the aperture range listed in the table (i.e. no large hole)

[0051] When DMF, EC, and DMAc are used to replace NMP in the examples, porous nickel hollow fiber membranes can also be obtained.

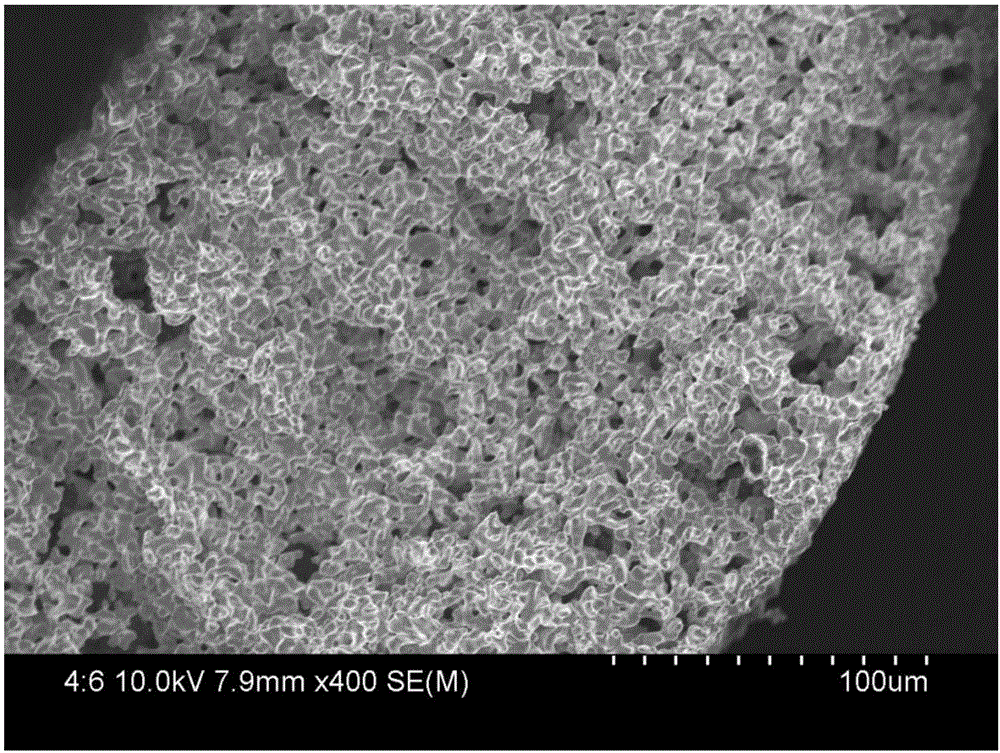

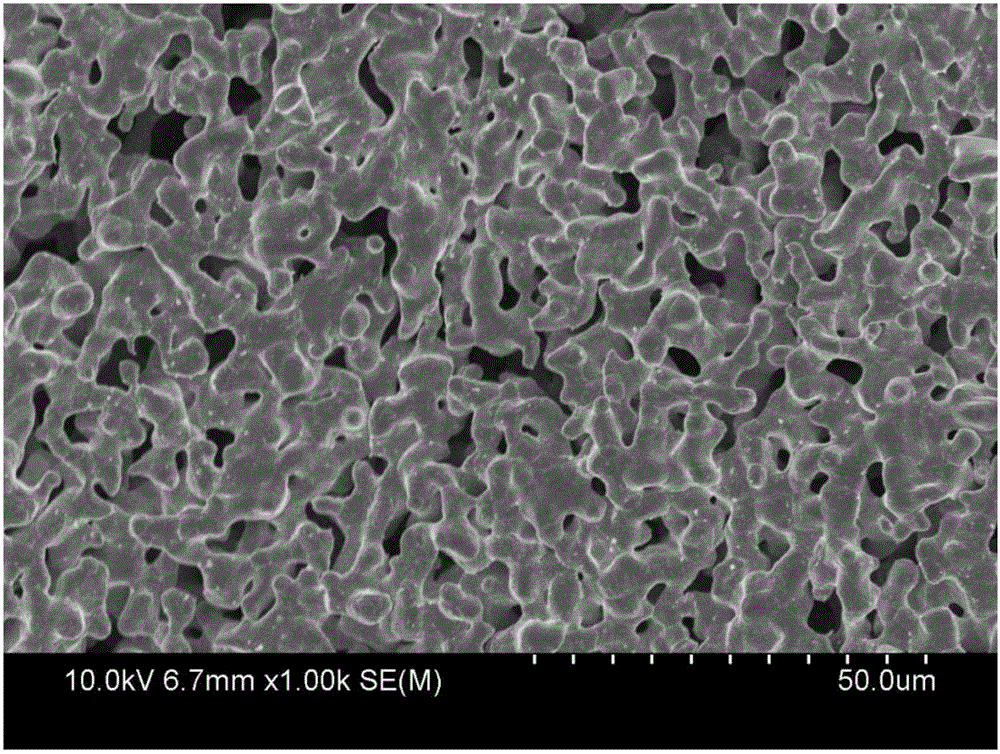

[0052] The porous nickel hollow fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com