Device and method for producing potassium sulfate by utilizing fluidized bed furnace reactor

A reactor and fluidized furnace technology, applied in the direction of sulfate/bisulfate preparation, energy input, etc., can solve the problems of using organic harmful solvents, complex process, high production cost, etc., to reduce equipment corrosion, high product quality, production The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

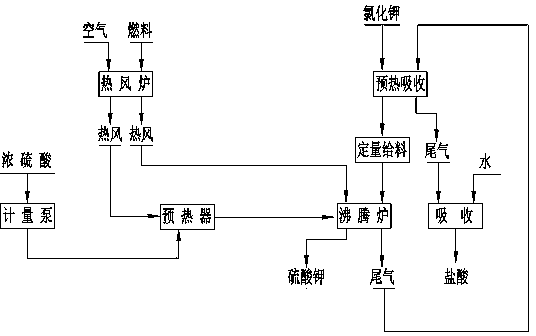

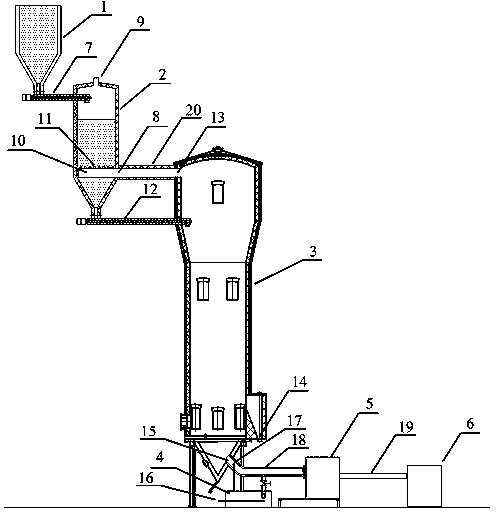

[0030] Embodiment 1 A kind of device and method for fluidized-bedded furnace technology to produce potassium sulfate, its device is mainly composed of potassium chloride material feeding device, potassium chloride preheater (2), fluidized-bedded furnace reactor (3), sulfuric acid preheater (4 ), hot blast stove (5) and other devices. Potassium chloride feeding device is composed of potassium chloride silo (1) and potassium chloride conveyor (7). Potassium chloride silo (1) is preheated by potassium chloride conveyor (7) The potassium chloride preheater (2) is lined with a wear-resistant protective layer and an insulation layer on the outside. The gas distribution pipe (10) is installed inside, and the hydrogen chloride gas outlet (9) is opened on the top, and the chlorine The potassium chloride metering conveyor (12), the gas distribution pipe (10) is equipped with a gas nozzle (11); the fluidized furnace reactor (3) is lined with a wear-resistant protective layer, and an oute...

Embodiment 2

[0034] Example 2 An apparatus and method for producing potassium sulfate by fluidized furnace process, the apparatus and method steps can still refer to Example 1. The difference is that the weight ratio of potassium chloride to sulfuric acid is 0.85:0.58, the sulfuric acid used is industrial sulfuric acid with a mass concentration of 93%, and the outlet temperature of the hot blast stove is controlled at 850°C.

Embodiment 3

[0035]Example 3 An apparatus and method for producing potassium sulfate by fluidized furnace process, the apparatus and method steps can still refer to Example 1. The difference is that the weight ratio of potassium chloride and sulfuric acid is 0.90:0.62, the sulfuric acid used is industrial sulfuric acid with a mass concentration of 96%, the potassium oxide content of the potassium chloride used is greater than 60%, and the outlet temperature of the hot blast stove is controlled at 950°C .

[0036] The table below is the comparison of the obtained potassium sulfate product quality and expected output in Example 1 of the present invention with the currently widely used Mannheim method. Therefore, the product quality of the present invention is high and stable, and the production output is large. In addition, the corrosion of equipment in the invention is reduced, and the amount of maintenance is reduced, thereby achieving the purpose of saving energy and reducing consumption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com