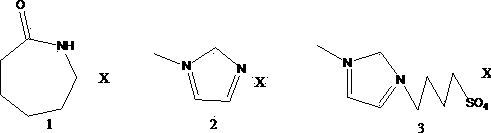

Method for synthesizing TNAD through catalytic nitration by using ionic liquid

An ionic liquid and catalyst technology, applied in the field of synthesizing TNAD, can solve the problems of potential safety hazard, increase production cost, and high reaction temperature, and achieve the effects of less equipment corrosion, increased safety, and simple reaction operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

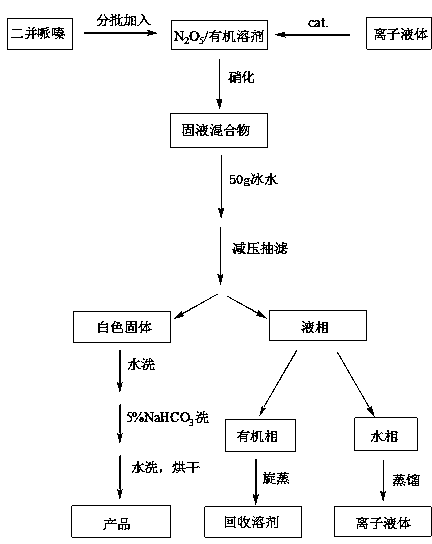

Method used

Image

Examples

Embodiment 1

[0028] Under ice bath, add 30mmol N to the four-neck flask 2 o 5 And 30ml of dichloromethane solvent, add 5mmol of dipiperazine in batches, control the temperature not to exceed 5°C, after the addition, raise the temperature to 25°C for 60min, after the reaction, pour the mixture into 50g of ice water, there is a white solid Precipitated, washed with water, 5% NaHCO 3 washing, washing with water until neutral, and drying to obtain TNAD with a yield of 77.6%.

Embodiment 2

[0030] The process was the same as in Example 1, but the reaction time was changed to 30 min to obtain TNAD with a yield of 48.2%.

Embodiment 3

[0032] The process was the same as in Example 1, but the reaction time was changed to 70 min to obtain TNAD with a yield of 77.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com