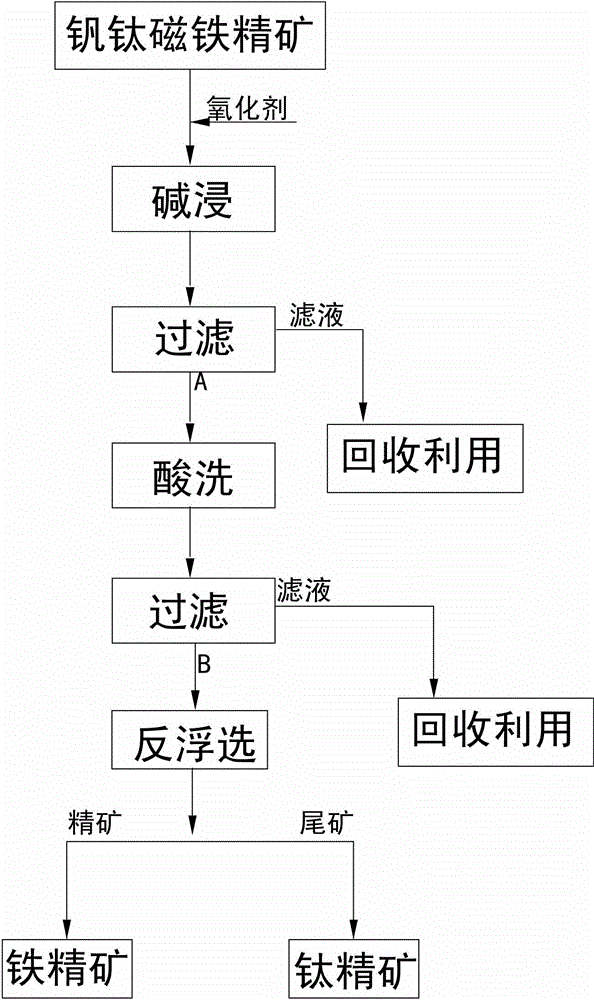

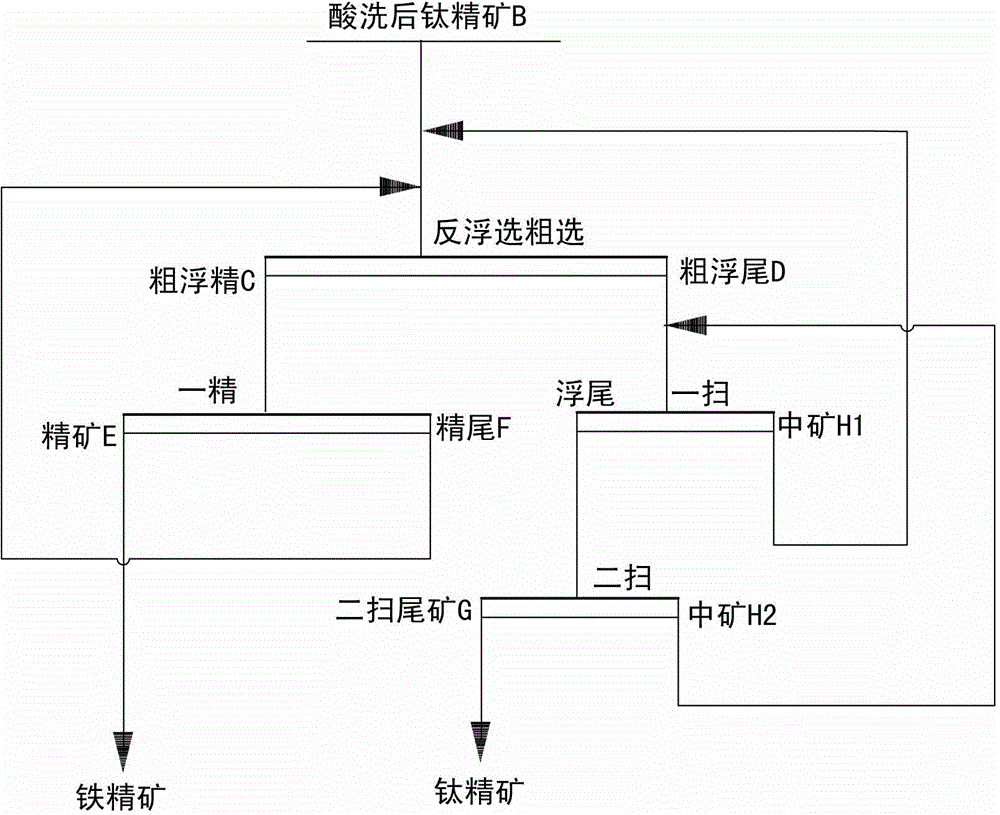

Method for re-concentrating vanadium-titanium magnetite concentrates by means of oxidized alkali leaching, acid pickling and reverse flotation

A vanadium-titanium-magnetite concentrate and oxidized alkali leaching technology is applied in flotation, process efficiency improvement, solid separation and other directions to achieve mild reaction conditions, reduce emissions, and reduce ironmaking costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

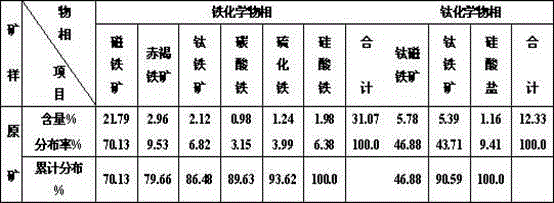

[0039] 1) Oxidative alkaline leaching

[0040] The TFe content is 51.2%, TiO 2 The content is 14.1%, SiO 2 The content is 3.66%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.51% and a S content of 0.58% was placed in a NaOH alkali solution with a mass concentration of 49%, and 98psi of O 2 , then alkali leaching reaction at a temperature of 320°C for 1.5 hours, and the reactants were filtered to obtain the filtrate and alkali leaching filter cake A. The NaOH consumption was 80.2 kg / t for ore feeding, and the filtrate was fed into the recovery treatment system, which The chemical reaction formula is:

[0041] 4mFeTiO 3 +8NaOH +mO 2 2mFe 2 o 3 ↓+4Na 2 O·(TiO 2 ) m ↓+4H 2 O m≥1

[0042] pFe 3 o 4 q (FeO TiO 2 ) +2rNaOH pFe 3 o 4 ↓+qFeO↓+ (Na 2 O) r ·(TiO 2 ) q ↓+rH 2 o

[0043] Al 2 o 3 +2NaOH 2NaAlO 2 + H 2 o

[0044] tSiO 2 +2NaOH Na 2 O (SiO 2 ) t ↓ + H 2 o

[0045] 3FeS 2 +6NaOH 3FeS↓+Na 2 SO 3 +2N...

Embodiment 2

[0060] 1) Oxidative alkaline leaching

[0061] The TFe content is 52.1%, TiO 2 The content is 13.6%, SiO 2 The content is 3.98%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.38% and a S content of 0.63% was placed in a NaOH alkali solution with a mass concentration of 41%, and 86psi of O 2 , then alkali leaching reaction at a temperature of 240°C for 2.0 hours, and the reactants were filtered to obtain the filtrate and alkali leaching filter cake A. The NaOH consumption was 78.5kg / t for ore feeding, and the filtrate was fed into the recovery treatment system, which Chemical reaction formula is with embodiment 1;

[0062] 2) pickling

[0063] Add water to the alkali leaching filter cake A in step 1) to make a slurry with a mass solid-to-liquid ratio of 1: 5, and then place it in H2O with a mass concentration of 4.5%. 2 SO 4 , pickling at 70°C for 40 minutes, filtering the pickling reactants to obtain the filtrate and acid leaching filter cake ...

Embodiment 3

[0070] 1) Oxidative alkaline leaching

[0071] The TFe content is 53.7%, TiO 2 The content is 12.4%, SiO 2 The content is 3.45%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.29% and a S content of 0.66% is placed in a NaOH alkali solution with a mass concentration of 32%, and 196kg / t of 给矿 H 2 o 2 , then alkali leaching reaction at a temperature of 315°C for 0.5 hour, the reactant was filtered to obtain the filtrate and alkali leaching filter cake A, the NaOH consumption was 75.9 kg / t to the ore, and the filtrate was fed into the recovery treatment system, which The chemical reaction formula is:

[0072] 2mFeTiO 3 +4NaOH+mH 2 o 2 mFe 2 o 3 ↓+2Na 2 O·(TiO 2 ) m ↓+(m+2)H 2 O m≥1

[0073] pFe 3 o 4 q (FeO TiO 2 ) +2rNaOH pFe 3 o 4 ↓+qFeO↓+ (Na 2 O) r ·(TiO 2 ) q ↓+rH 2 o

[0074] Al 2 o 3 +2NaOH 2NaAlO 2 + H 2 o

[0075] tSiO 2 +2NaOH Na 2 O (SiO 2 ) t ↓ + H 2 o

[0076] 3FeS 2 +6NaOH 3FeS↓+Na 2 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com