Aluminum alloy neutral zirconium-tungsten conversion liquid and preparation method of zirconium-tungsten conversion film on surface of aluminum alloy

An aluminum alloy surface, aluminum alloy technology, applied in the direction of climate sustainability, metal material coating process, reduction of greenhouse gases, etc., can solve the problems of high production cost, unfavorable storage and transportation, etc., to achieve less equipment corrosion and conversion time. Short, safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

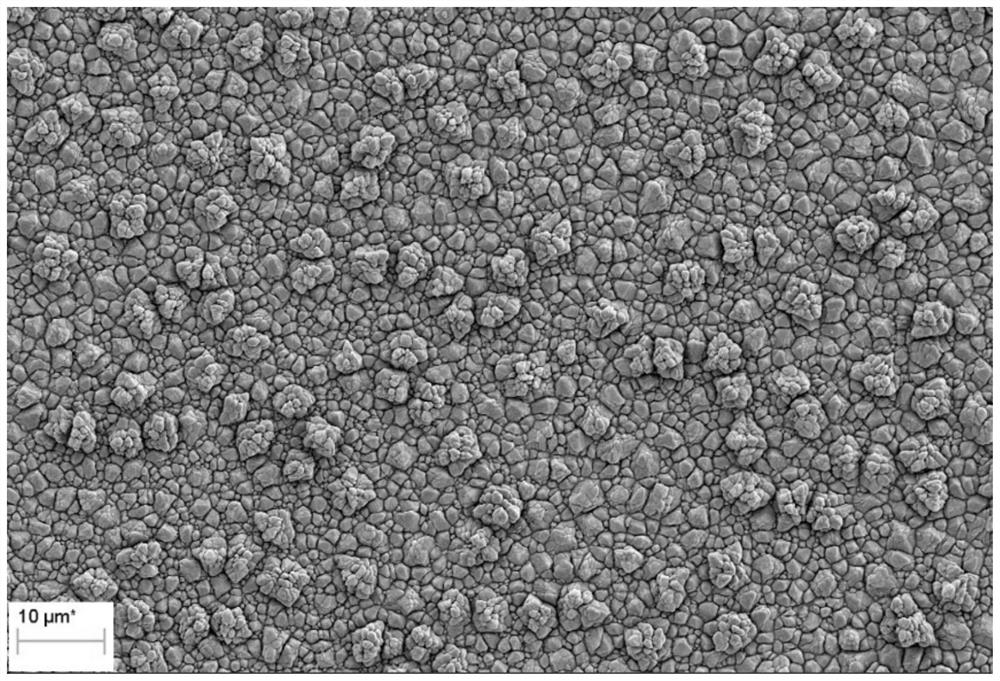

[0038] The preparation method of the aluminum alloy neutral zirconium-tungsten conversion solution and the colored conversion film of the present embodiment is carried out according to the following steps:

[0039] (1) Preparation of an aluminum alloy neutral zirconium-tungsten conversion solution: weigh 8.0g of disodium EDTA, 2.0g of tannic acid, 4.0g of fluorozirconic acid, 3.0g of ammonium bifluoride, and 6.0g of tungstic acid. sodium. Accurately measure 700ml of deionized water, pour it into a 1000ml beaker, and add the above weighed reagents into the beaker in turn. When adding fluorozirconic acid, it needs to be slowly added dropwise without stirring. The rest of the reagents need to be stirred and dissolved at room temperature. Add the remaining reagents; add deionized water to 980ml, adjust the pH to 6.7, and replenish water to 1000ml to obtain the neutral zirconium-tungsten conversion solution.

[0040] (2) Substrate preparation: cut 6063 aluminum alloy into 30.0×30....

Embodiment 2

[0046] The preparation method of the aluminum alloy neutral zirconium-tungsten conversion solution and the colored conversion film of the present embodiment is carried out according to the following steps:

[0047] (1) Preparation of an aluminum alloy neutral zirconium-tungsten conversion solution: weigh 5.0g of disodium EDTA, 1.0g of tannic acid, 1.4g of fluorozirconic acid, 2.3g of ammonium bifluoride, and 2.5g of tungstic acid. sodium. Accurately measure 700ml of deionized water, pour it into a 1000ml beaker, and add the above weighed reagents into the beaker in turn. When adding fluorozirconic acid, it needs to be slowly added dropwise without stirring. The rest of the reagents need to be stirred and dissolved at room temperature. Add the remaining reagents; add deionized water to 980ml, adjust pH to 6.8, and replenish water to 1000ml to obtain the neutral zirconium-tungsten conversion solution.

[0048] (2) Substrate preparation: same as Example 1;

[0049] (3) Pickling...

Embodiment 3

[0053] The preparation method of the aluminum alloy neutral zirconium-tungsten conversion solution and the colored conversion film of the present embodiment is carried out according to the following steps:

[0054] (1) Preparation of an aluminum alloy neutral zirconium-tungsten conversion solution: Weigh 10.0 ethylenediaminetetraacetic acid disodium, 1.5 g tannic acid, 2.5 g fluorozirconic acid, 6.0 ammonium hydrogen hydride, and 7.0 sodium tungstate respectively. Accurately measure 700ml of deionized water, pour it into a 1000ml beaker, and add the above weighed reagents into the beaker in turn. When adding fluorozirconic acid, it needs to be slowly added dropwise without stirring. The rest of the reagents need to be stirred and dissolved at room temperature. Add the remaining reagents; add deionized water to 980ml, adjust the pH to 7.0, and replenish water to 1000ml to obtain the neutral zirconium-tungsten conversion solution.

[0055] (2) Substrate preparation: same as Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

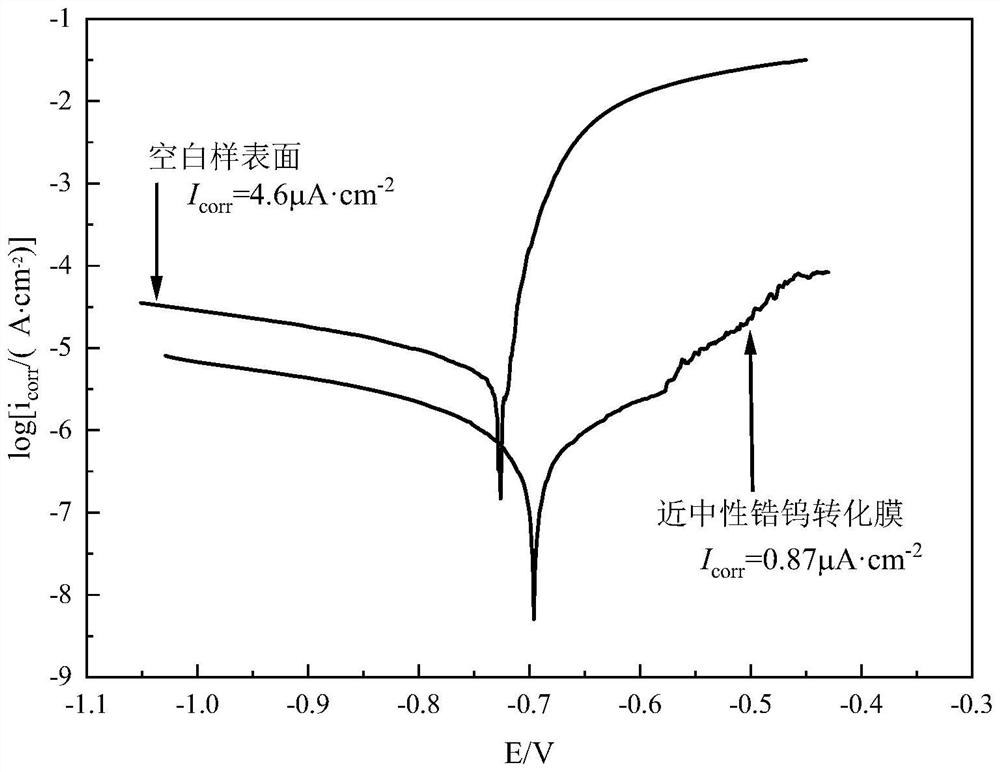

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com