Technology for preparing acetic esterand device thereof

An acetate and process technology, which is applied in the field of acetate preparation process and its equipment, can solve the problems of equipment corrosion, high pressure of wastewater treatment, easy occurrence of side reactions, etc., achieve light equipment corrosion, high conversion rate, and solve the problem of containing The effect of the sulfur problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

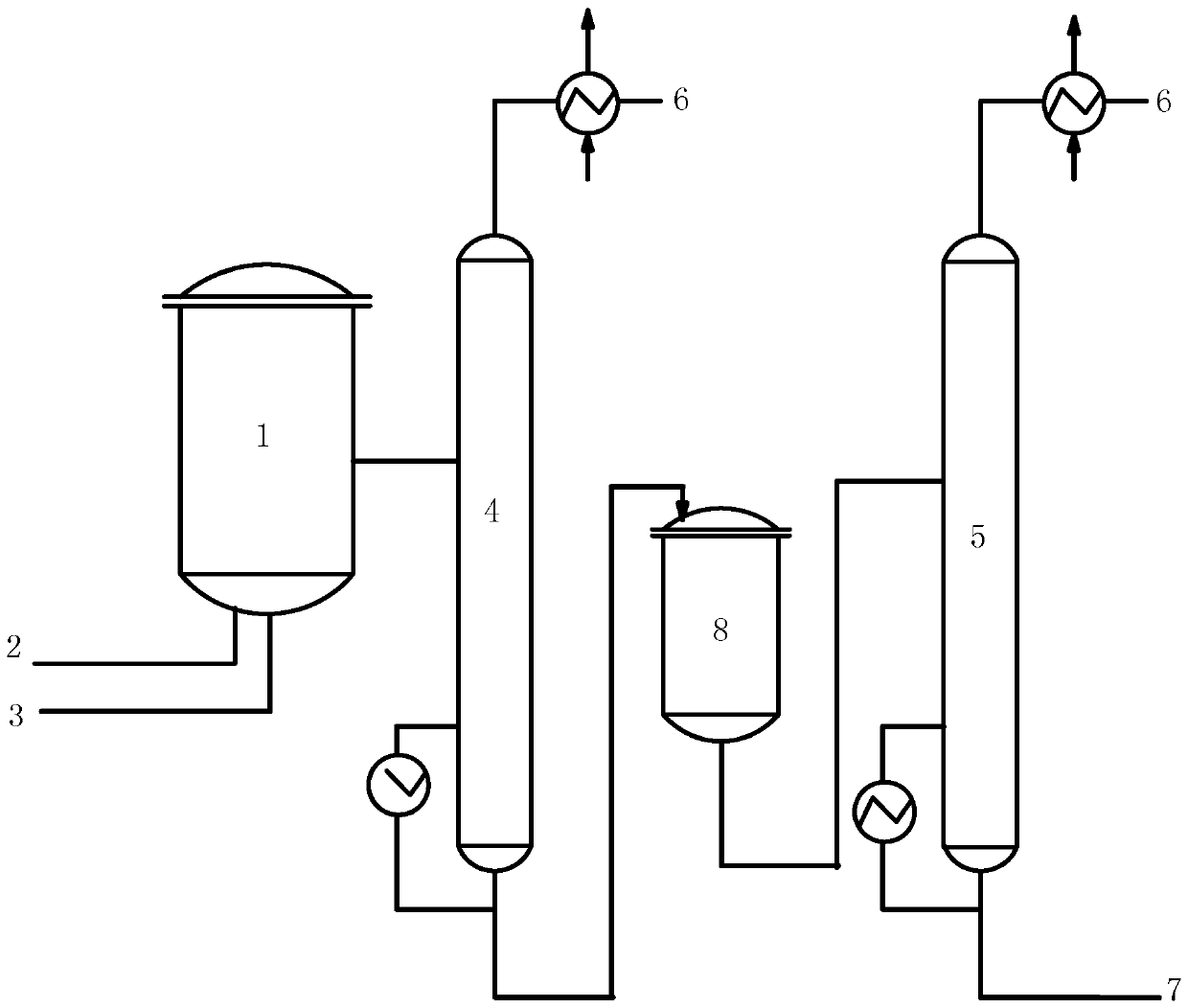

[0018] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 shown.

[0020] A process for preparing acetate, said process comprising the following steps:

[0021] (1) Esterification, acetic acid and alcohol raw materials continuously enter the esterification kettle 1, by controlling the temperature and pressure of the esterification kettle 1, under the absence of sulfuric acid catalysis, acetic acid and alcohol raw materials undergo esterification reaction to generate acetate and water;

[0022] (2) Product rectification, acetate and unreacted acetic acid and alcohol raw materials in step 1 enter primary rectification tower 4 from esterification kettle 1, separate acetate, acetic acid, unreacted alcohol and a large amount of water , the unreacted raw material enters an intermediate esterification kettle 8 equipped with solid acid, and the acetic acid and alcohol raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com