Preparation process of high-activity anti-condensation calcium hydroxide

A calcium hydroxide, preparation technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, chemical industry, sustainable manufacturing/processing, etc., can solve the problem of general calcium hydroxide yield, high labor intensity, Problems such as large energy loss, to achieve the effect of improving structural stability, facilitating filtration and removal of impurities, and ensuring firm installation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A kind of preparation technology of high activity anticoagulation calcium hydroxide of the present invention comprises the following steps:

[0040] (1) High temperature calcination treatment:

[0041] First, the surface of the quicklime block is cleaned and washed to remove the soil and impurities on the surface, and then the cleaned quicklime block is transported to the calciner, and the calcium oxide stone is obtained after high-temperature calcination;

[0042] (2) Crushing and screening of calcium oxide stones:

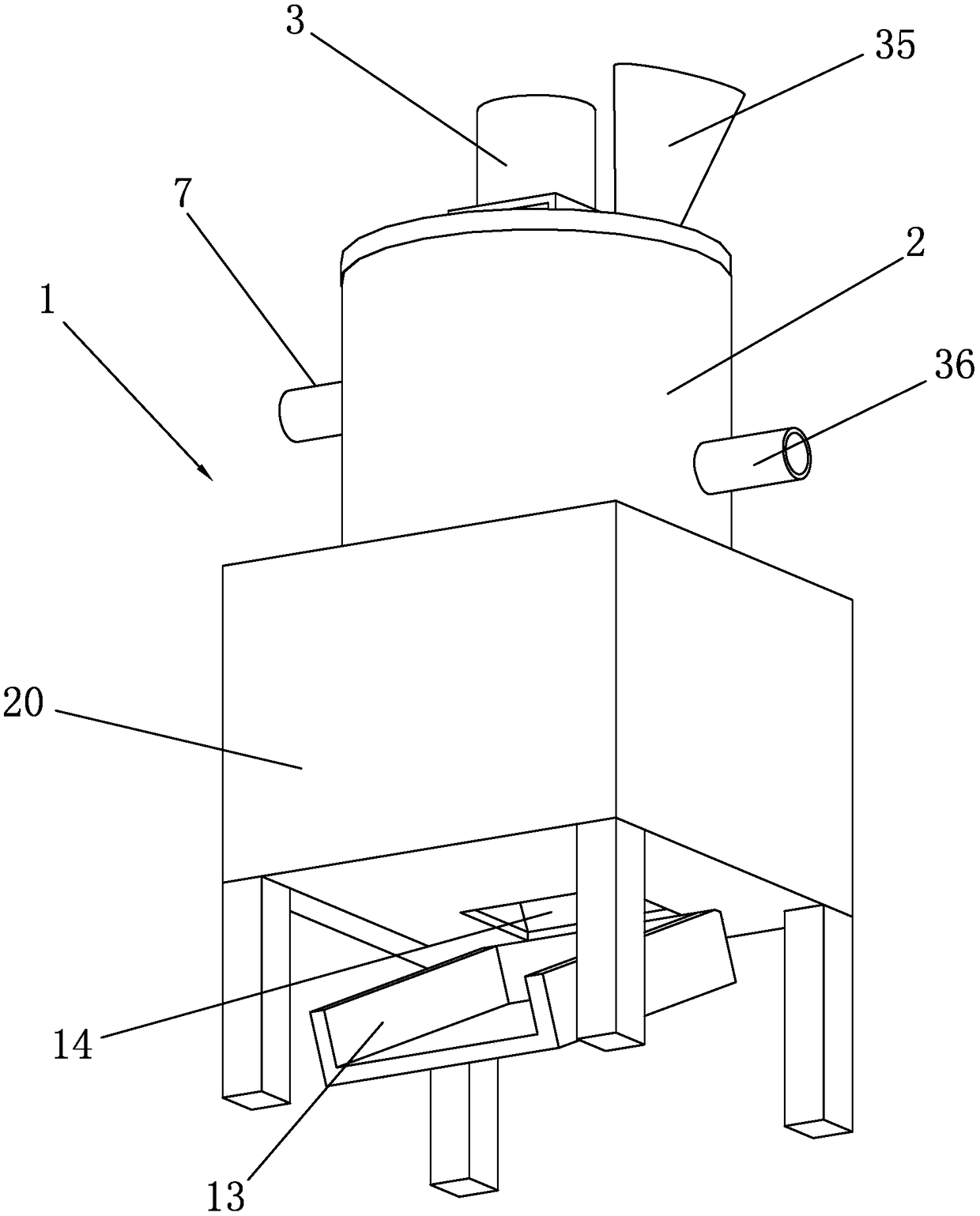

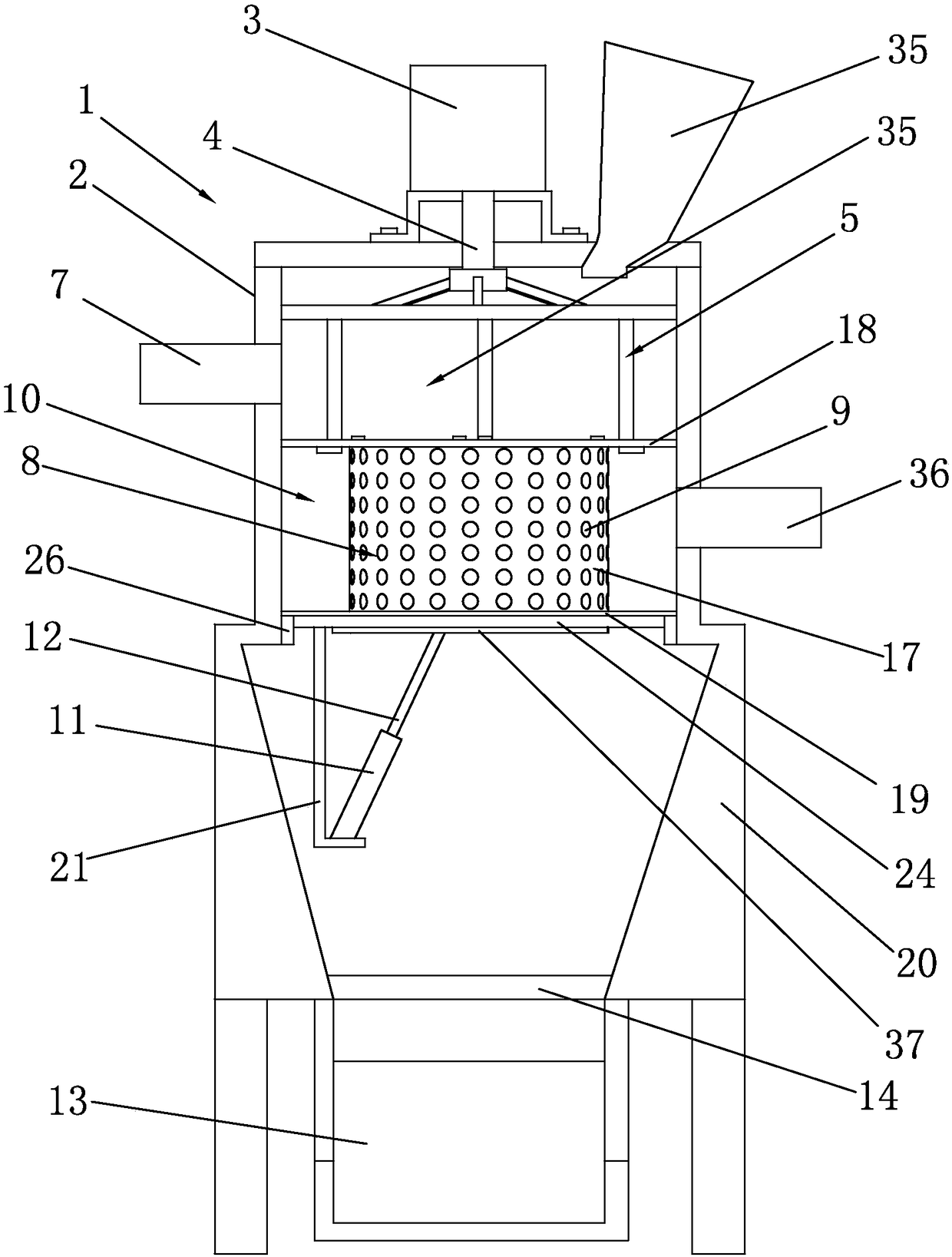

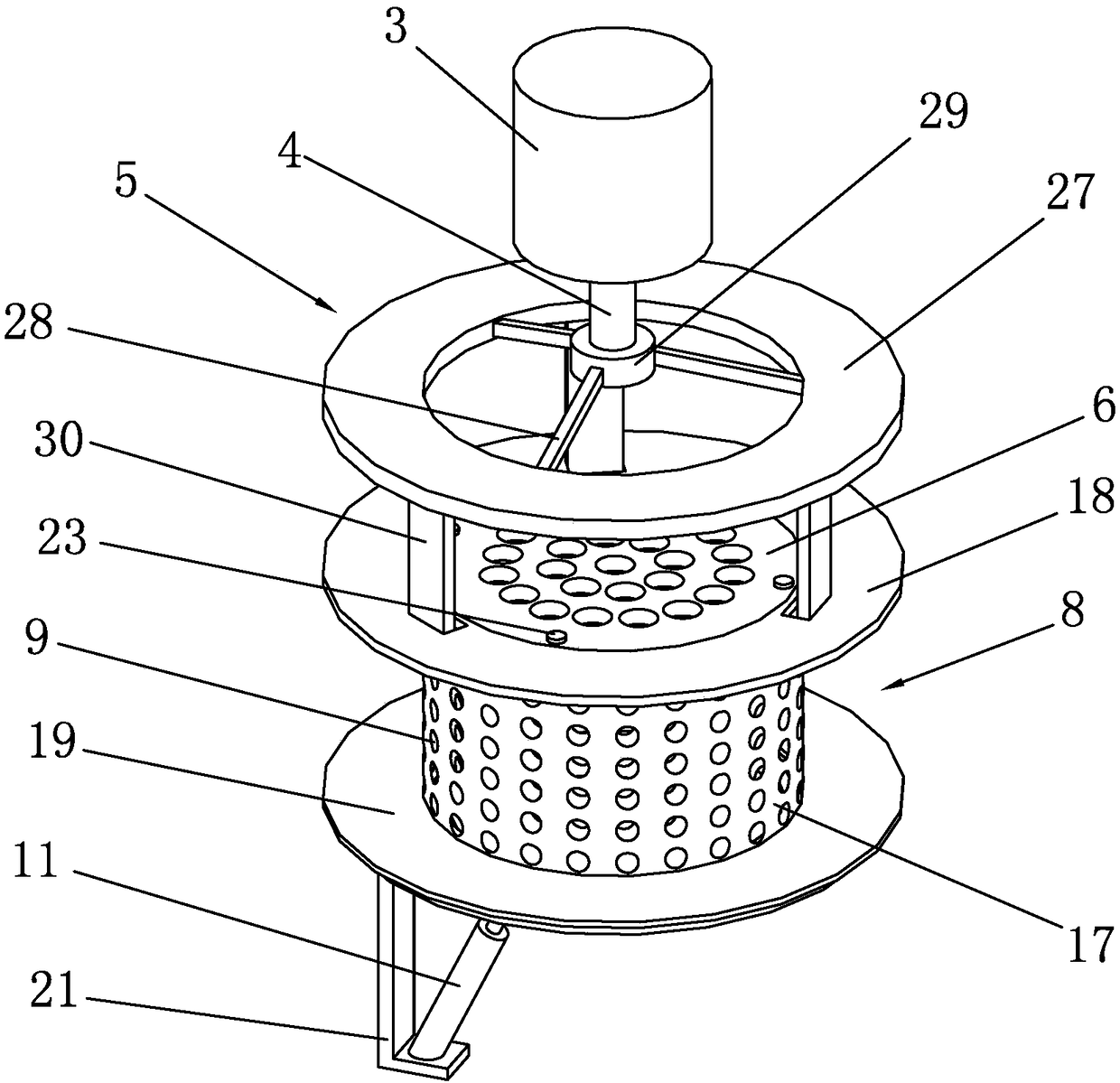

[0043] a, the calcium oxide stone obtained in the step (1) is added in the crusher, and the calcium oxide stone is transported to the screening machine 1 by the conveying device after being crushed by the crushing device on the inner wall of the crusher;

[0044] b. The crushed calcium oxide stones are weighed by metering, quantitatively enter the screening machine 1 from the feed pipe 35, and the rotating motor 3 is started at the same time, and the rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com