Production method of polyamide 6FDY complete-extinction crystal yarn

A production method and full extinction technology, which is applied in the field of textile and chemical fibers, can solve the problems of unsatisfactory performance indicators, lack of market competitiveness, and different performance, so as to improve market competitiveness, enrich the three-dimensional effect, and accelerate the cooling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

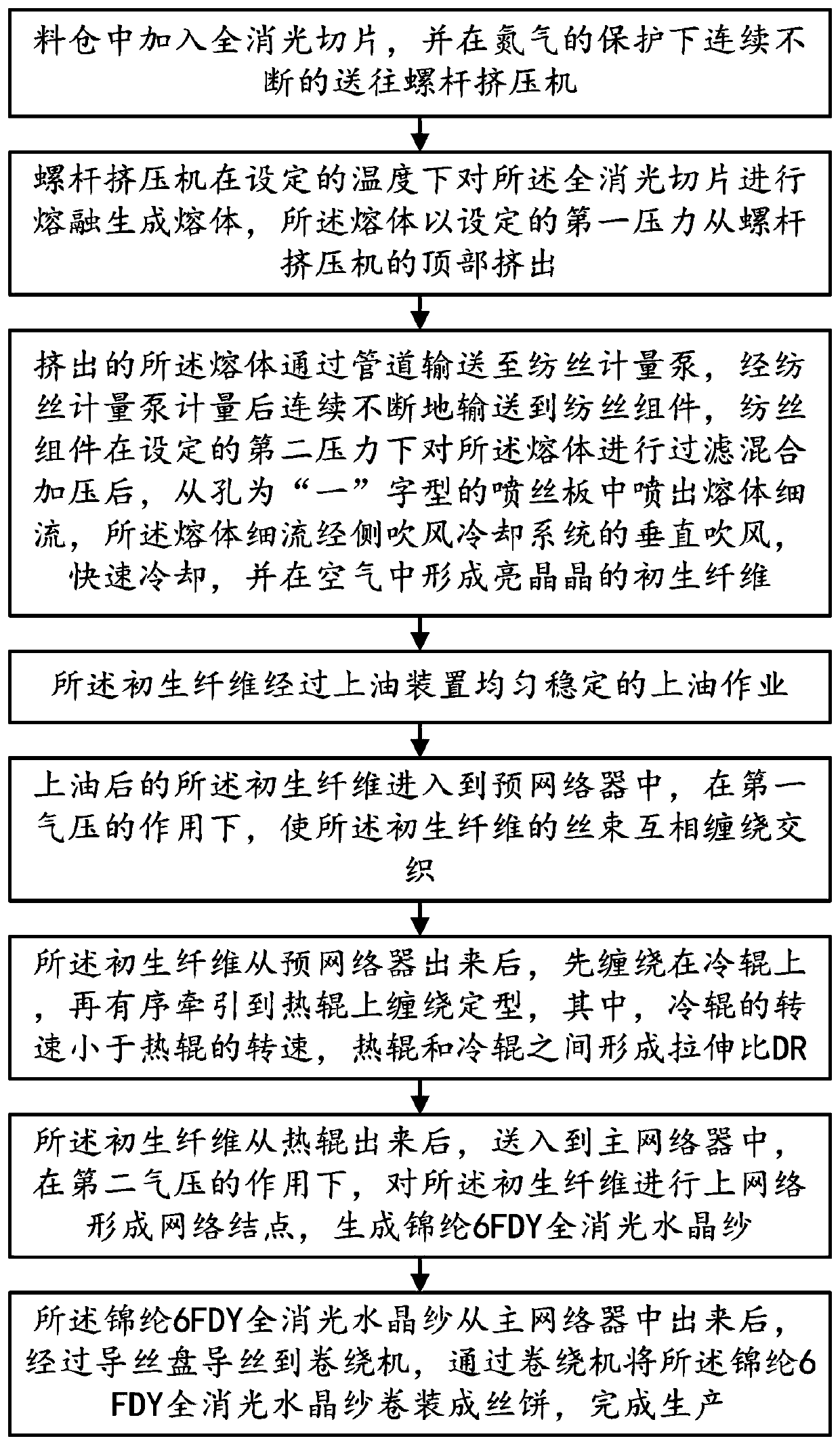

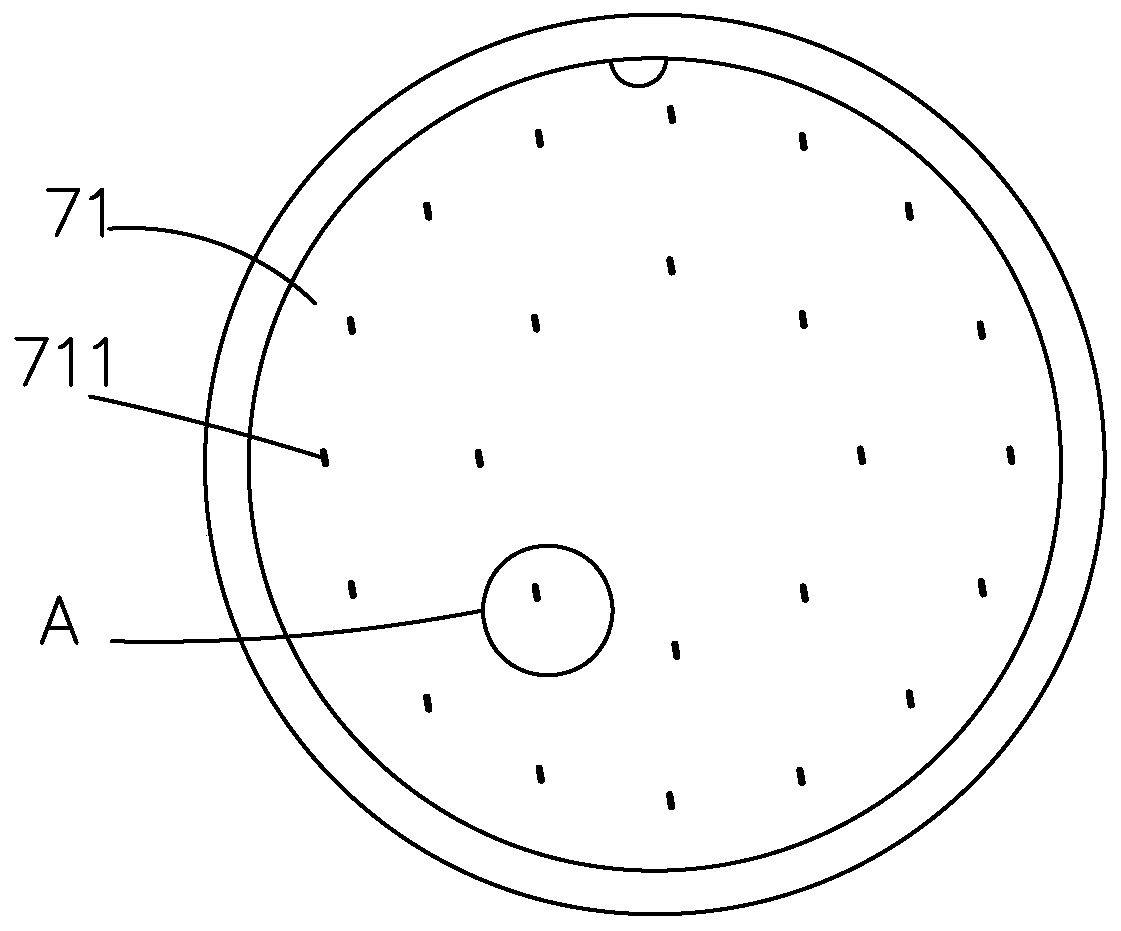

[0034] The general idea of the technical solution in the embodiment of the present application is as follows: the blowing of the spinneret by the side blowing cooling system is changed from side blowing to positive blowing, and the cooling speed is accelerated, and the melt stream is crystallized under rapid cooling to form sparkles Glowing highlights.

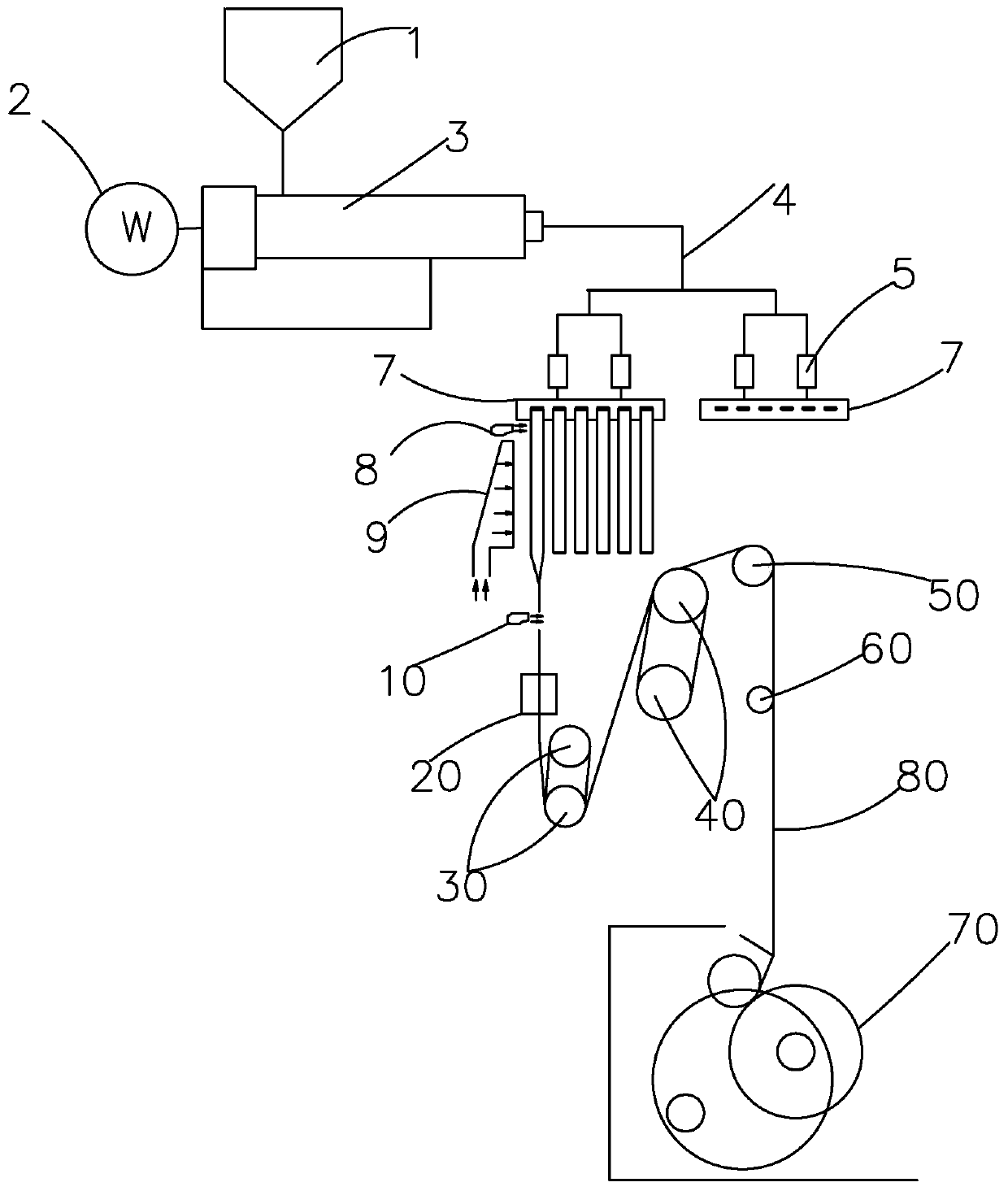

[0035] Please refer to Figure 1 to Figure 3 As shown, a preferred embodiment of a nylon 6FDY full-dull crystal yarn production method of the present invention comprises the following steps:

[0036] Step S10, adding full-dull slices into the silo 1, and continuously sending them to the screw extruder 3 under the protection of nitrogen;

[0037] Step S20, the screw extruder 3 melts the full-dull slice at a set temperature to generate a melt, and the melt is extruded from the top of the screw extruder 3 at a set first pressure; the screw extruder The press 3 is driven by the drive motor 2;

[0038] Step S30, the extruded m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com