Raw material pretreatment solvent extraction system and method for needle coke industrial production

A needle coke and pretreatment technology, which is applied in the process of selective solvent extraction tar processing and multi-stage series refining process treatment, etc., can solve the problem of complex actual operation of the process, high content of quinoline insolubles, and short service life of equipment. and other problems, to achieve the effect of simple operation process, reduction of quinoline insoluble content, and stable operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

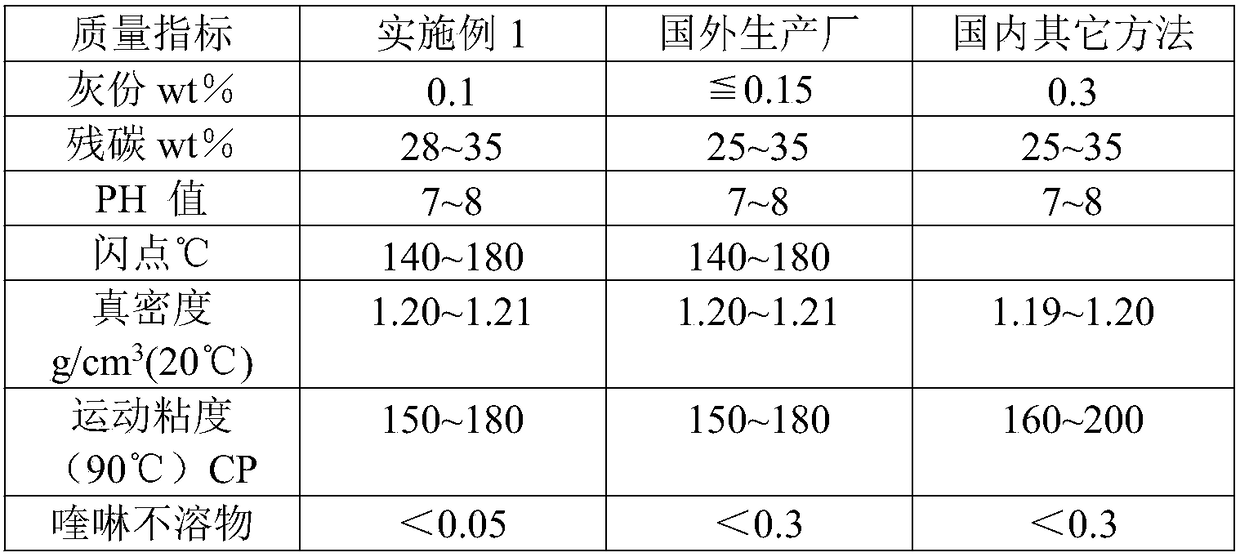

Embodiment 1

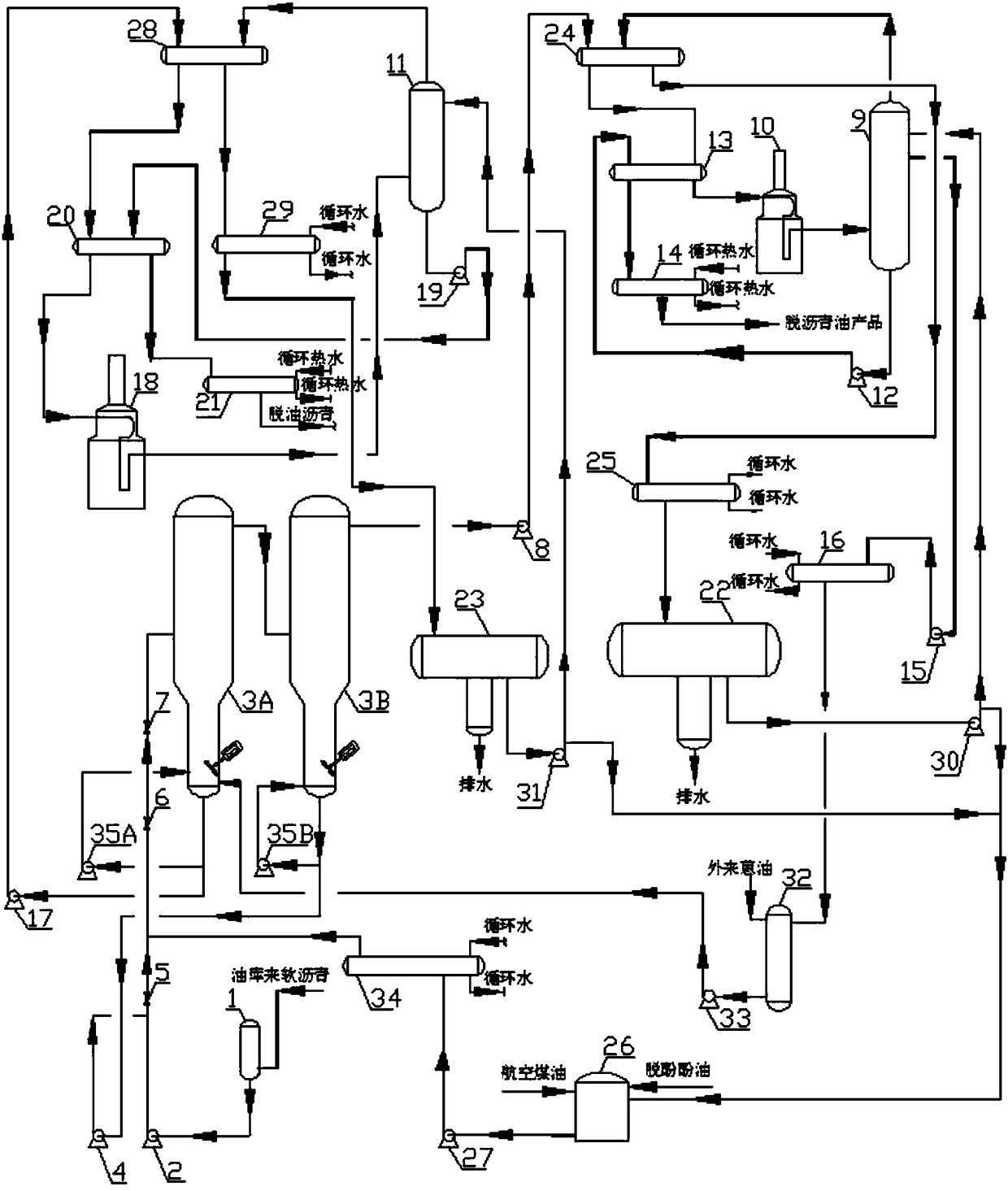

[0029] Such as figure 1 As shown, the raw material pretreatment solvent extraction system for needle coke industrial production in this embodiment includes a raw material buffer tank 1, a raw material oil pump 2, a first extractor 3A, a second extractor 3B, and a first asphalt solution pump 4 , primary mixer 5, secondary mixer 6, tertiary mixer 7, deasphalted oil solution pump 8, deasphalted oil stripper 9, deasphalted oil solution heating furnace 10, deoiled asphalt stripper Tower 11, deasphalted oil pump 12, deasphalted oil solution-deasphalted oil heat exchanger 13, deasphalted oil cooler 14, second asphalt solution pump 17, deoiled asphalt solution heating furnace 18, deoiled asphalt pump 19, deasphalted oil Oil asphalt solution-deoiled asphalt heat exchanger 20, deoiled asphalt cooler 21, first solvent tank 22, second solvent tank 23, deasphalted oil solution-solvent heat exchanger 24, first solvent aftercooler 25, Mixed solvent tank 26, mixed solvent pump 27, deoiled as...

Embodiment 2

[0059] The principle of this embodiment is the same as that of Embodiment 1, and the following content only introduces the differences between this embodiment and Embodiment 1.

[0060] In this embodiment, in step 1, the temperature of the soft asphalt entering the raw material buffer tank 1 from the raw material tank of the oil depot is 130°C, and the ratio of the mixed solvent entering from the mixed solvent tank 26 to the soft asphalt is 1:0.5;

[0061] In step 2, the deasphalted oil solution from the deasphalted oil solution outlet on the top of the second extractor 3B enters the deasphalted oil solution-solvent heat exchanger 24 through the deasphalted oil solution pump 8, and the deasphalted oil solution-solvent In the heat exchanger 24, the deasphalted oil solvent coming out of the deasphalted oil solvent outlet at the top of the deasphalted oil stripper 9 is heat-exchanged to 130° C. and then enters the deasphalted oil solution-deasphalted oil heat exchanger 13, and Th...

Embodiment 3

[0067] The principle of this embodiment is the same as that of Embodiment 1, and the following content only introduces the differences between this embodiment and Embodiment 1.

[0068] In this embodiment, in step 1, the temperature of the soft asphalt entering the raw material buffer tank 1 from the raw material tank of the oil depot is 160°C, and the ratio of the mixed solvent entering from the mixed solvent tank 26 to the soft asphalt is 1:2;

[0069] In step 2, the deasphalted oil solution from the deasphalted oil solution outlet on the top of the second extractor 3B enters the deasphalted oil solution-solvent heat exchanger 24 through the deasphalted oil solution pump 8, and the deasphalted oil solution-solvent In the heat exchanger 24, the deasphalted oil solvent that comes out of the deasphalted oil solvent outlet at the top of the deasphalted oil stripping tower 9 is heat-exchanged to 180° C. and then enters the deasphalted oil solution-deasphalted oil heat exchanger 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com