Hydrogenation catalyst, preparation method and application thereof, and hydrogenation reaction method

A hydrogenation catalyst and hydrogenation reaction technology, applied in catalyst activation/preparation, hydrogenation preparation, chemical elements of heterogeneous catalysts, etc., can solve the problems of difficult continuous production and low activity, and achieve high product quality and high catalytic activity. , product quality and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

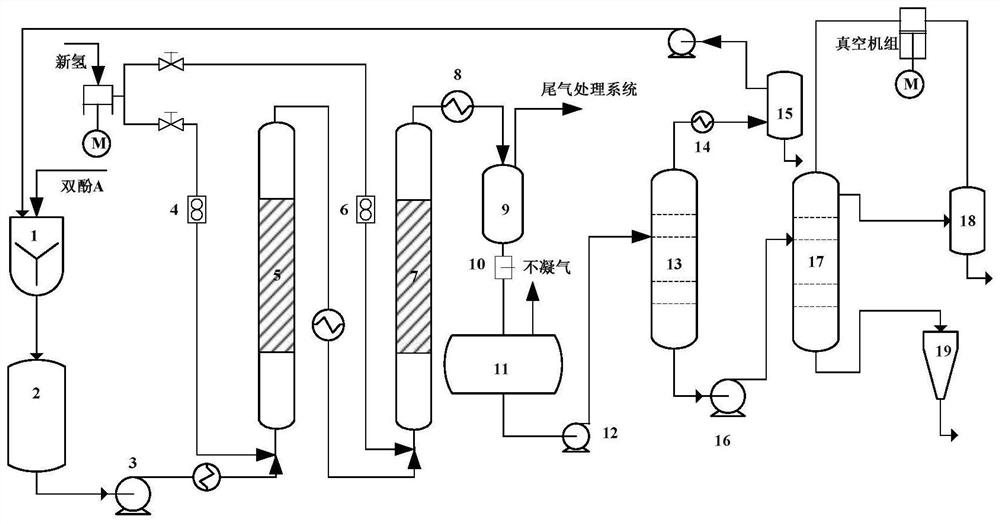

[0044] According to a second aspect of the present invention, the present invention provides a method for preparing a hydrogenation catalyst, the method comprising the following steps:

[0045] (1) contacting the precipitating agent with a solution containing a nickel compound and a zirconium compound, and separating the solid-phase substance from the mixture obtained by contacting to obtain a precipitate;

[0046] (2) mixing the precipitate with a VIB group metal compound and an aluminum-containing compound, and successively drying, calcining and molding the obtained mixture to obtain a catalyst precursor, wherein the VIB group metal compound is a group VIB metal oxide compounds and / or precursors of Group VIB metal oxides, said aluminum-containing compounds being alumina and / or precursors of alumina;

[0047] (3) contacting the catalyst precursor with a reducing agent under reduction reaction conditions.

[0048] In step (1), the nickel compound and the zirconium compound ar...

preparation example 1

[0103] In this embodiment, the hydrogenation catalyst A is: based on the total amount of the catalyst, the content of nickel element is 30% by weight, the molybdenum oxide (MoO 3 ) content was 5% by weight, the content of zirconia was 20% by weight, and the content of alumina was 45% by weight. Prepared in the following way:

[0104] (1) The aqueous solution containing nickel nitrate and zirconium nitrate and the aqueous solution containing sodium hydroxide and sodium carbonate (the molar ratio of sodium hydroxide: sodium carbonate is 1:2) are co-currently co-currently mixed at 40°C with stirring. Precipitation, controlling the pH value of the end point to be 11, filtering the obtained reaction mixture, and washing the collected solid matter with deionized water 5 times to obtain a nickel-zirconium coprecipitate.

[0105] (2) The nickel-zirconium precipitate is mixed with molybdenum oxide and pseudo-boehmite, slurried, then dried at 120°C for 6 hours, and then calcined at 500...

preparation example 2

[0108] In this preparation example, the hydrogenation catalyst B is: based on the total amount of the catalyst, the content of nickel element is 50% by weight, the content of molybdenum oxide is 0.5% by weight, the content of zirconia is 30% by weight, and the content of alumina is 19.5% by weight . Prepared in the following way:

[0109] (1) Mix an aqueous solution containing nickel chloride and zirconium chloride with an aqueous solution containing potassium hydroxide and sodium carbonate (the molar ratio of potassium hydroxide:sodium carbonate is 1:3) at 60°C with stirring. Flow co-precipitation, controlling the pH value of the end point to be 12, filtering the obtained reaction mixture, washing the collected solid material with deionized water 6 times to obtain nickel-zirconium co-precipitate.

[0110] (2) The nickel zirconium precipitate is mixed with molybdenum oxide and pseudo-boehmite, slurried, then dried at 100°C for 6 hours, then calcined at 400°C for 5 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com