Factory assembled latticed light steel structure and manufacturing method thereof

A factory-assembled, light-steel structure technology, applied in truss structures, building structures, building components, etc., can solve the problem that small and medium-sized light-steel structures can only be made by welding, improve bearing capacity and rigidity, and have good versatility , the effect of high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

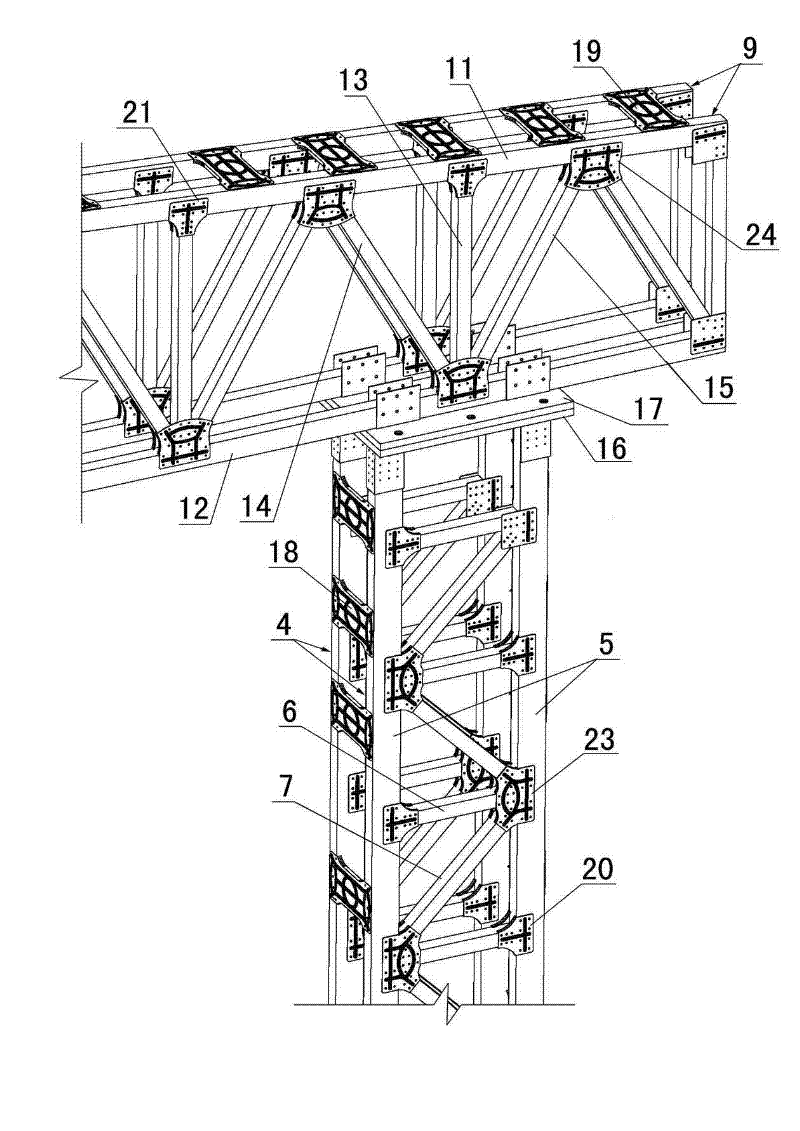

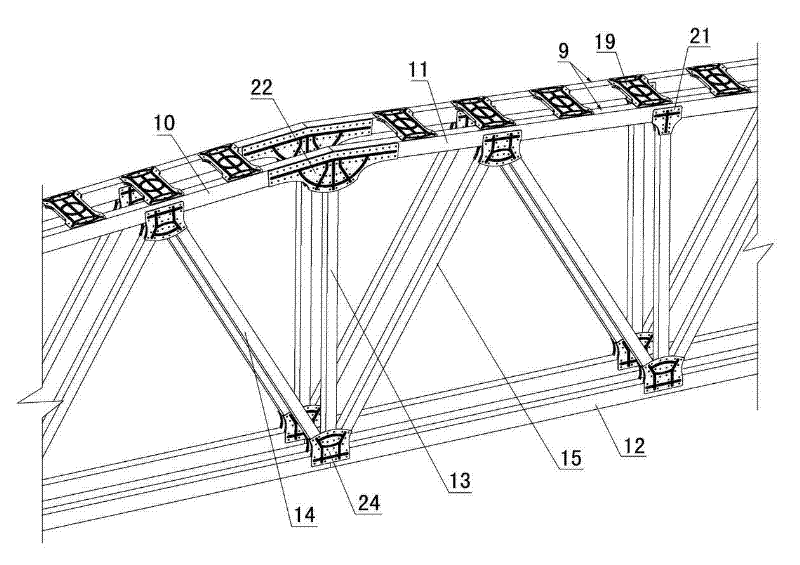

[0046] Examples see Figure 1-4 As shown, this factory-assembled lattice light steel structure is composed of frames distributed in parallel at intervals and beams 1 fixedly connected between the frames. The frame includes two lattice columns 2 and fixedly placed on two lattice columns. The roof trusses 3 between the tops of the columns 2, the beams 1 are fixedly connected between the roof trusses 3.

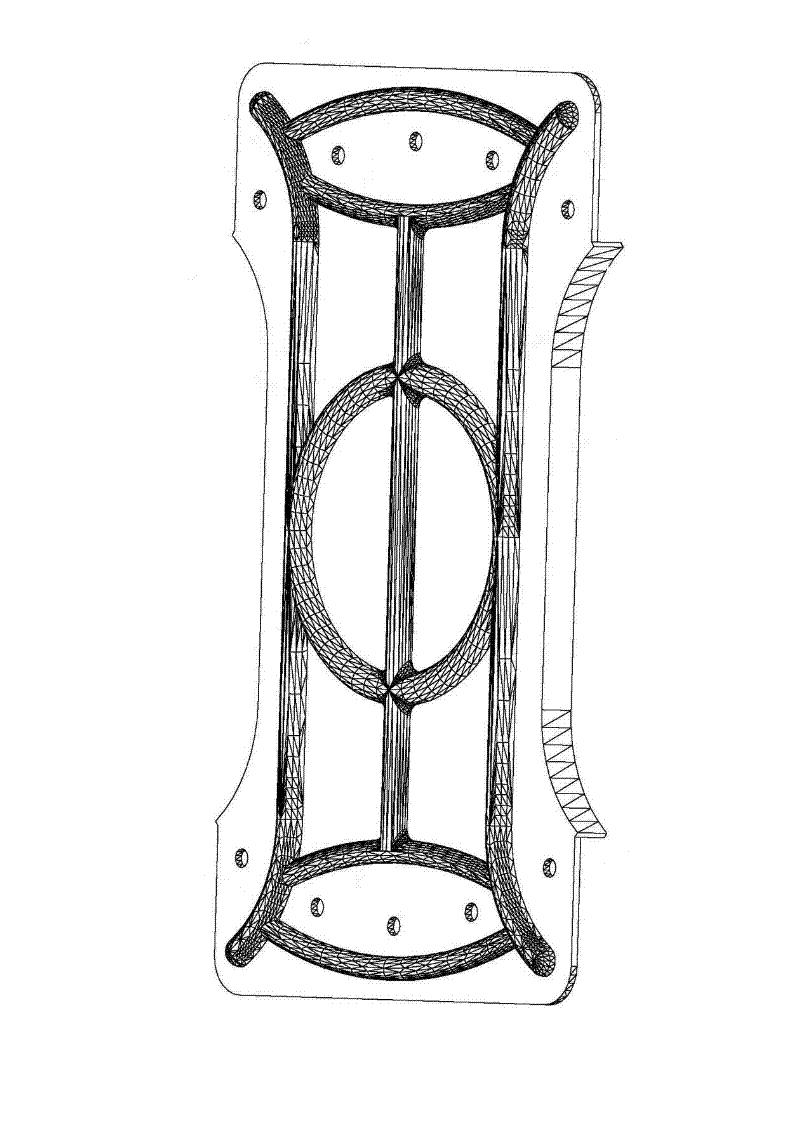

[0047] The lattice column 2 includes two relatively parallel sheet columns 4, a middle support connecting plate 18 for the sheet column connected between the two sheet columns 4 by self-tapping screws, and a connecting plate 18 connected to the bottom of the sheet column 4 by self-tapping screws. The foundation connector 8 (bolt holes are provided on the foundation connector to connect the foundation), and the roof truss connector 16 connected to the top of the sheet column 4 by self-tapping screws, the sheet column 4 includes two vertical rods 5, connecting The transverse webs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com